Method for desulfurizing waste gas and reutilizing sulfur source

A waste gas desulfurization and waste gas technology, which is applied in the field of desulfurization of sulfur dioxide-containing waste gas and recycling of sulfur resources, can solve the problems of secondary pollution and high desulfurization cost, and achieve the effects of fast desulfurization speed, high desulfurization rate and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

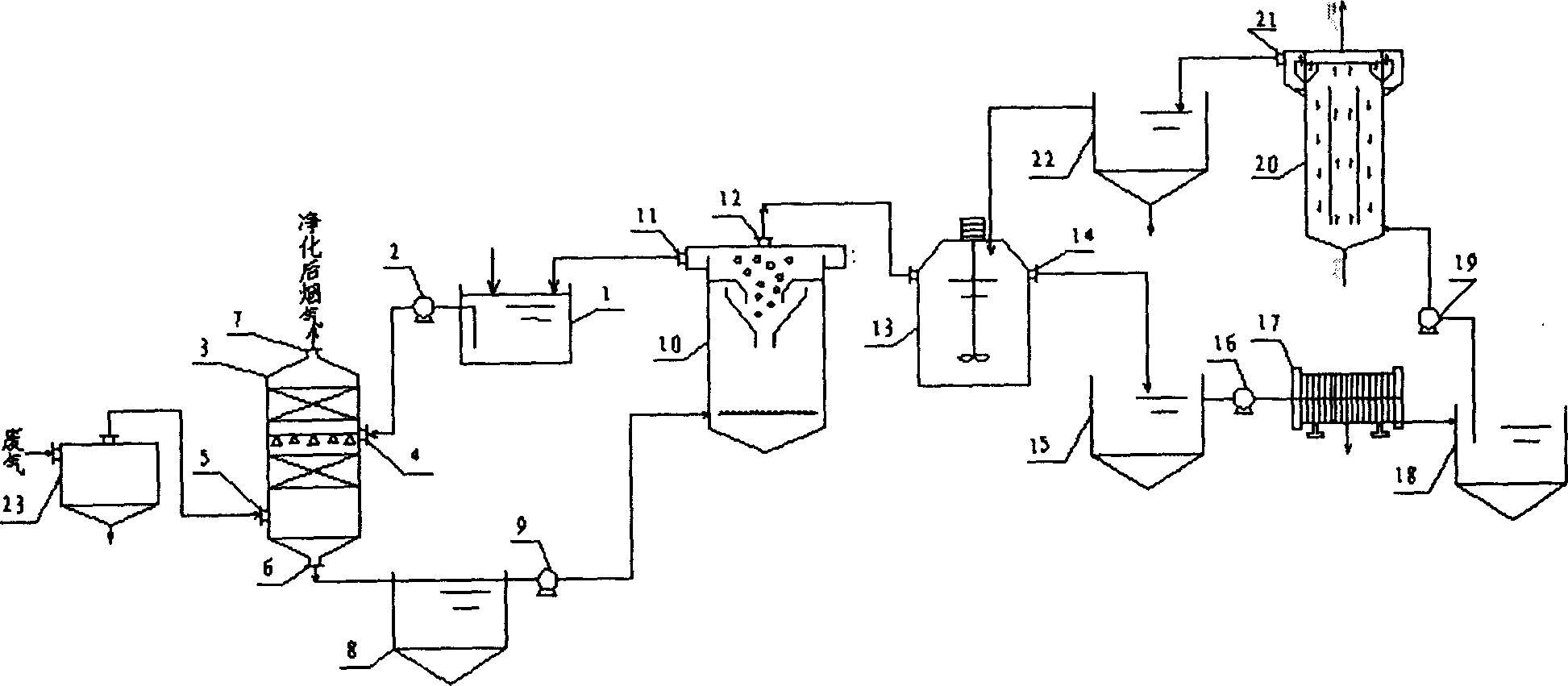

[0032] Using sodium carbonate (Na 2 CO 3 ) lye is the absorption liquid, adopts the inventive method to remove sulfur dioxide (SO 2 ), to recover sulfur resources from waste gas, to achieve the purpose of treating waste with waste and recycling sulfur resources. Taking the treatment of a coal-fired boiler with a scale of 35T / h as an example, the amount of exhaust gas to be treated is 60000Nm 3 / h, the exhaust gas temperature is 180°C, and the sulfur dioxide content in the exhaust gas is 1500ppm.

[0033] The process flow of this embodiment is shown in the figure. 5% sodium carbonate (Na 2 CO 3 ) lye is pumped into the waste gas absorption device from the lye pool 1 through the water inlet 4 on the upper part of the waste gas absorption device 3 through the water inlet 4 on the upper part of the waste gas absorption device 3, and at the same time, the flue gas from the coal-fired boiler is dedusted by the dust collector 23 and then enters through the waste gas inlet at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com