Indium phosphide-base quantum cascade semiconductor laser and producing method

An indium-based quantum technology and a fabrication method are applied in the field of indium phosphide-based quantum cascade semiconductor lasers and fabrication, and can solve problems such as serious heating of devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

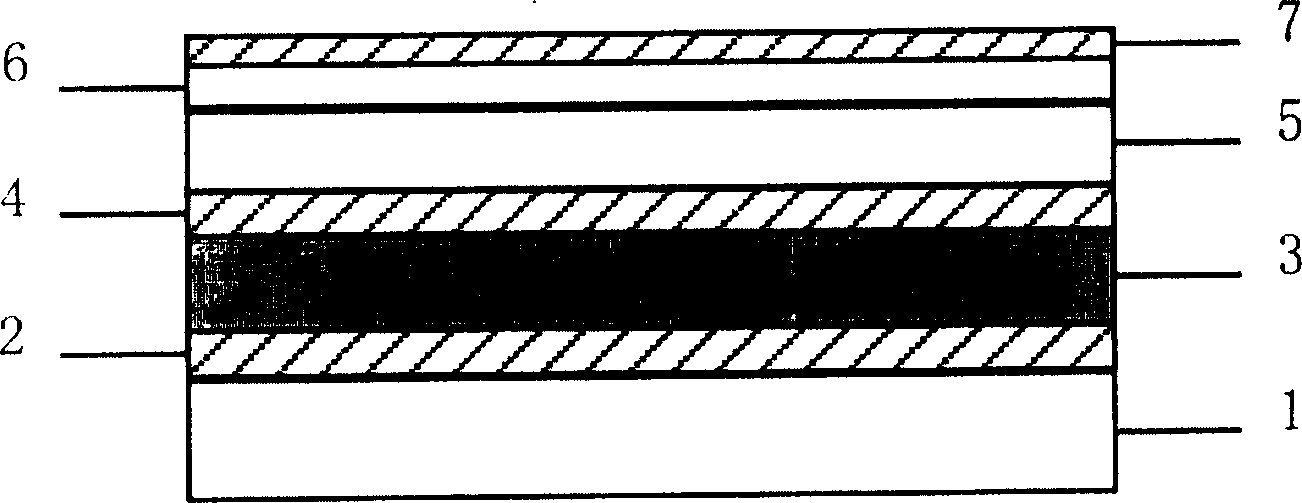

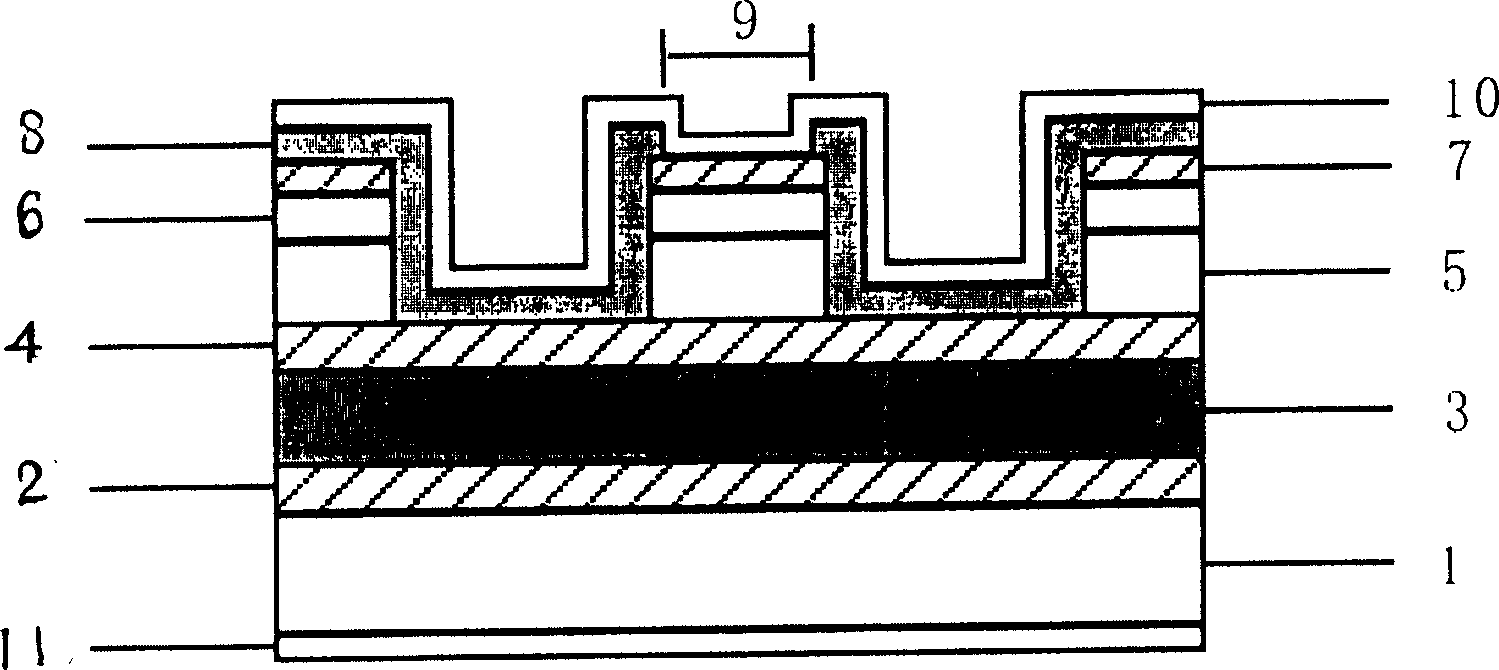

[0033] figure 1 It is a schematic diagram of the material structure of a quantum cascade semiconductor laser. Using molecular beam epitaxy (MBE) growth technology to grow a layer of N-type InGaAs lower waveguide layer 1 on the N-type InP substrate 1, and then grow 35 cycles of active regions 3 alternating InGaAs and InAlAs, and then grow N-type InGaAs The upper waveguide layer 4, because our solid-source MBE equipment does not have a P source, so after growing the waveguide core, the sample is cleaned with concentrated sulfuric acid, and then transferred to a metal-organic chemical vapor deposition (MOCVD) system to continue growing. layer N-type InP upper cladding layer 5, then grow N-type InP contact layer 6, and finally grow highly doped N-type InGaAs ohmic contact layer 7.

[0034] The device is a double-groove-ridge waveguide structure, and the epitaxial surface of the device is welded on the copper heat sink to further reduce the heat generation of the device. After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com