Zein nano fiber porous film and preparation method

A nanofiber, zein technology, applied in medical science, prosthesis, etc., can solve the problems of expensive solvent and harmful environment, and achieve the effect of good biocompatibility, good permeability, and good clinical repair effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

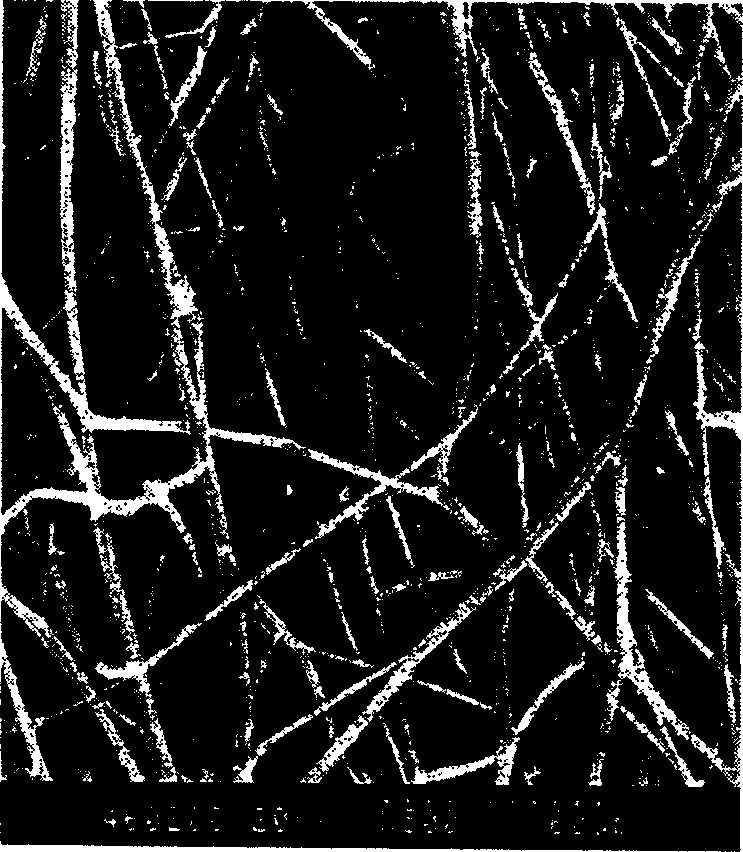

[0041] The preparation method of zein nanofiber porous membrane is to dissolve zein in a solvent to obtain an electrospinning solution, or dissolve additives in the above solution to obtain an electrospinning mixture, add it to a storage tank, and connect it to a or multiple injection heads, the injection head is connected to a DC high-voltage electric field, the voltage is positive or negative 3 kV-120 kV, the receiving device is grounded, and electrospinning is performed to obtain ribbon-shaped zein nanofibers, and the ribbon-shaped nanofibers are randomly stacked A zein nanofiber porous membrane is obtained, the transverse dimension of the nanofiber is 20 nanometers to 10 micrometers, and the pore size of the porous membrane is 100 nanometers to 100 micrometers. Alternatively, the obtained zein nanofiber porous membrane is soaked in a crosslinking agent solution, dried to obtain a crosslinked zein nanofiber porous membrane, and then soaked in an additive solution. The cross...

Embodiment 1

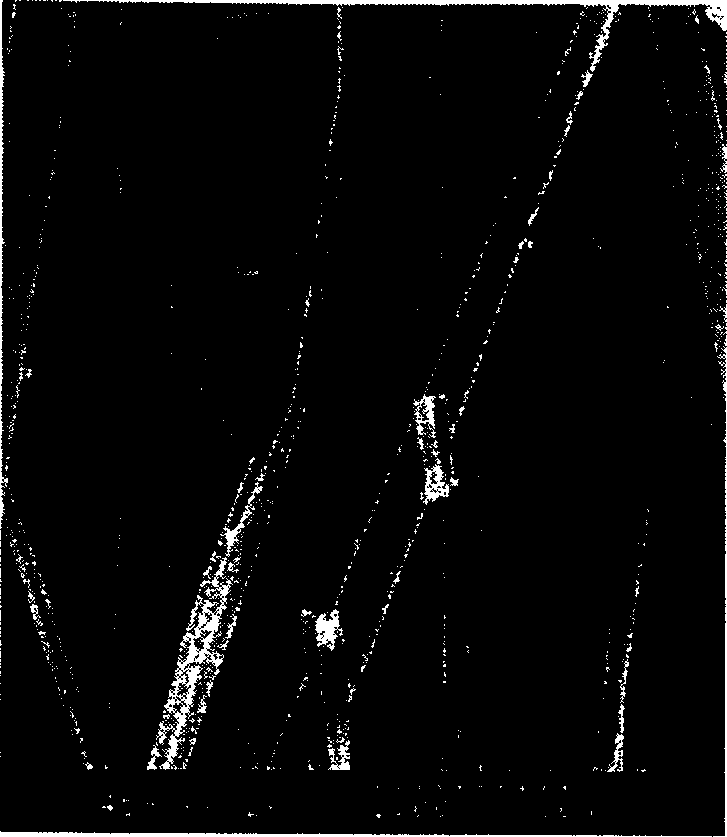

[0046] Dissolve 5 grams of zein in a mixed solvent of 10 ml of ethanol and water, the volume ratio of ethanol and water is 70:30, and make a 50% (w / v) polymer solution, then add it to the storage tank, and pass the syringe pump Connect the catheter to the nozzle, connect the nozzle to a high-voltage positive electric field, control the distance between the nozzle and the receiver at about 10cm, the solution flow rate is 6ml / h, and the voltage is 15kV, and electrospinning is performed to obtain nanofiber membrane materials. Electron microscope observation (see attached figure 1 ), the nanofiber is a ribbon structure, and the transverse dimension of the fiber is between 100 nanometers and 4 microns.

Embodiment 2

[0048] Dissolve 3 grams of zein in a mixed solvent of 10 ml of ethanol and water, the volume ratio of ethanol and water is 90:10, and make a 30% (w / v) polymer solution, then add it to the storage tank, and use the syringe pump Connect the catheter to the nozzle, connect the nozzle to a high-voltage positive electric field, control the distance between the nozzle and the receiver at about 10cm, the solution flow rate is 6ml / h, and the voltage is 10kV. Electrospinning is performed to obtain ribbon-shaped nanofibers, nano The fibers are randomly packed into a zein nanofiber film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

| Hole size | aaaaa | aaaaa |

| Horizontal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com