Catheter stent preparation method for repairing tubular tissue and organ and apparatus thereof

A catheter stent and tissue technology, which is applied in the field of catheter stent preparation, can solve problems such as difficult control of stent pore size and microporous structure, complicated operation of fiber weaving method, and time-consuming dipping method, so as to promote tissue reconstruction and functional recovery, equipment Simple, convenient and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

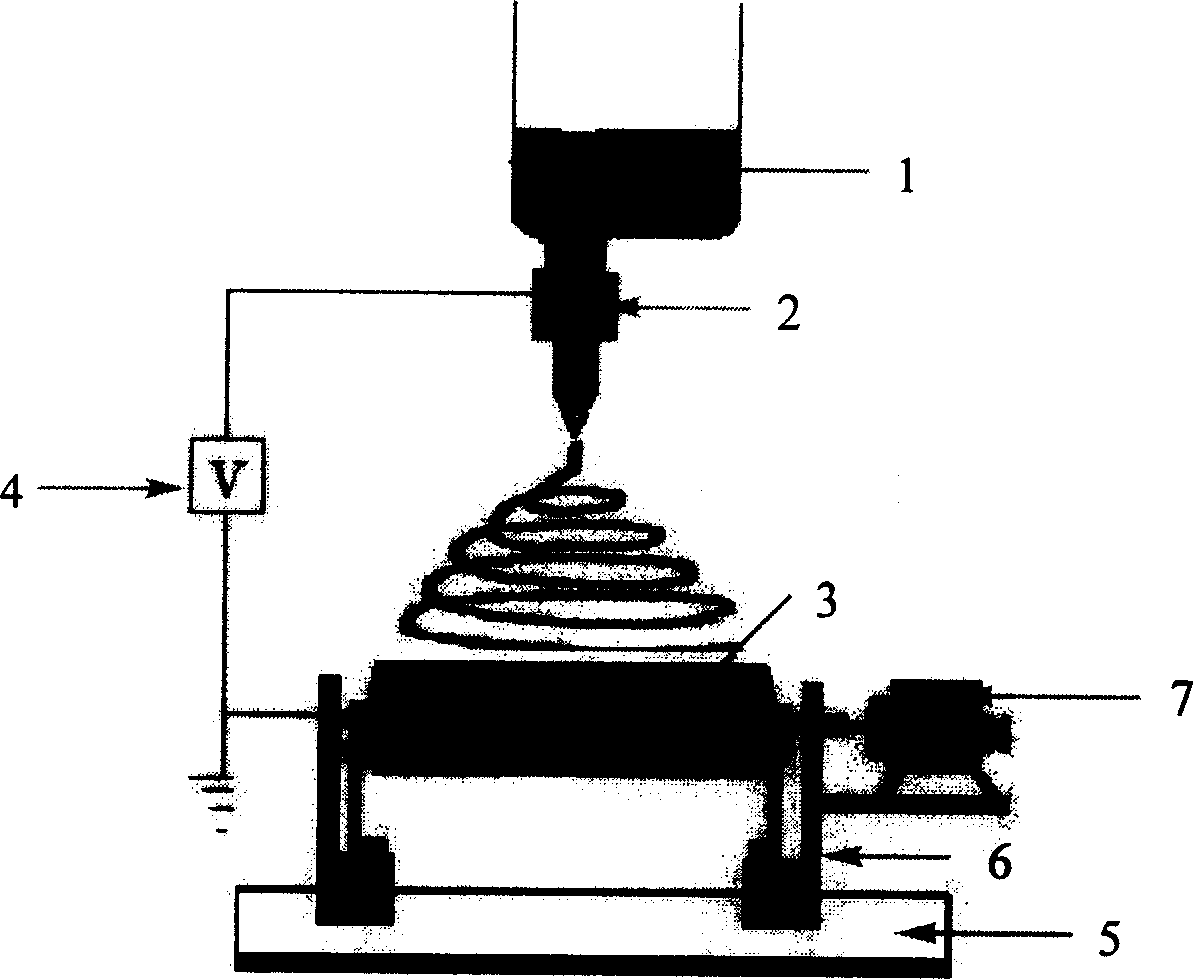

[0024] Polycaprolactone (PCL, Mn 42,500, Aldrich) 2g was dissolved in 10mL dimethylformamide (DMF) / chloroform mixed solvent (volume ratio 4 / 6), placed figure 1 In the feeder shown, the feeding speed of the spinning solution is controlled by a syringe pump; the spinning voltage is 10kV; a mandrel with a diameter of 6mm is selected, the mandrel speed is 200 rpm, and the axial speed is 0-0.15 m / s . According to the above conditions, by changing the collection time, tubular fiber scaffolds with an inner diameter of about 6 mm and different wall thicknesses can be obtained. The fiber diameter is around 750nm.

Embodiment 2

[0026] Polycaprolactone (PCL, Mn 42,500, Aldrich) 2g was dissolved in 10mL dimethylformamide (DMF) / chloroform mixed solvent (volume ratio 4 / 6), placed figure 1 In the feeder shown, the feeding speed of the spinning solution is controlled by a syringe pump; the spinning voltage is 10kV; a mandrel with a diameter of 1mm is selected, the mandrel speed is 200 rpm, and the axial speed is 0-0.15 m / s . According to the above conditions, by changing the collection time, tubular fiber scaffolds with an inner diameter of about 1 mm and different wall thicknesses can be obtained. The fiber diameter is around 700nm.

Embodiment 3

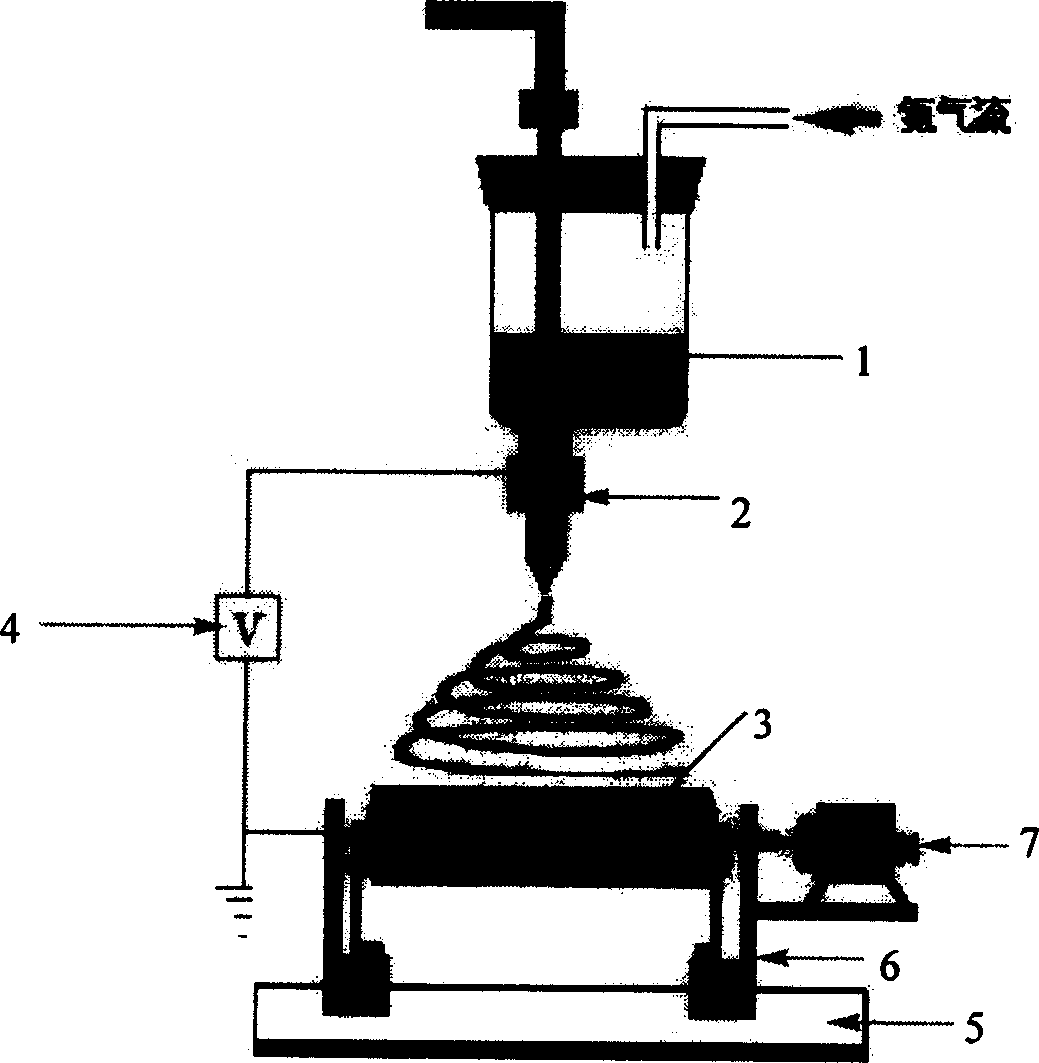

[0028] Polycaprolactone (PCL, Mn 42,500, Aldrich) 3g was dissolved in 10ml dimethylformamide (DMF) / chloroform mixed solvent (volume ratio 3 / 7), placed figure 1 In the outer chamber of the feeder shown; 2g dextran (Mn70,000, domestic) and 400mg BSA were dissolved in 10ml deionized water, placed in figure 1 In the feeder shown in the inner chamber; the PCL solution in the outer chamber is extruded from the spinning head by nitrogen flow, and the dextran solution in the inner chamber is pushed out of the spinning head by a syringe pump, and the applied voltage is 14.0kV; the diameter is 1.5mm Mandrel, the mandrel rotating speed is 300 rpm, and the axial speed is 0-0.2 m / s. Under the above conditions, a tubular scaffold composed of core-shell nanofibers with PCL as the shell and dextran / BSA as the core can be conveniently prepared, with a fiber diameter of about 600 nm. image 3 Optical photographs for the preparation of large-diameter catheter stents. Figure 4 is a scanning el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com