Liquid resin composition, cured film and laminate

A technology of liquid resin and composition, applied in the direction of synthetic resin layered products, cellulose plastic material layered products, coatings, etc., can solve the problems of insufficient scratch resistance, etc., and achieve excellent adhesion and scratch resistance Strong, good anti-reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

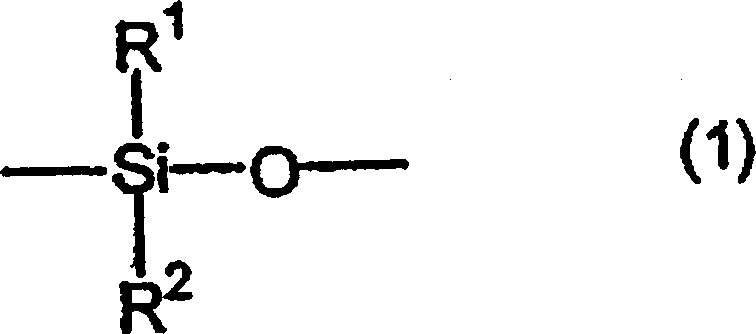

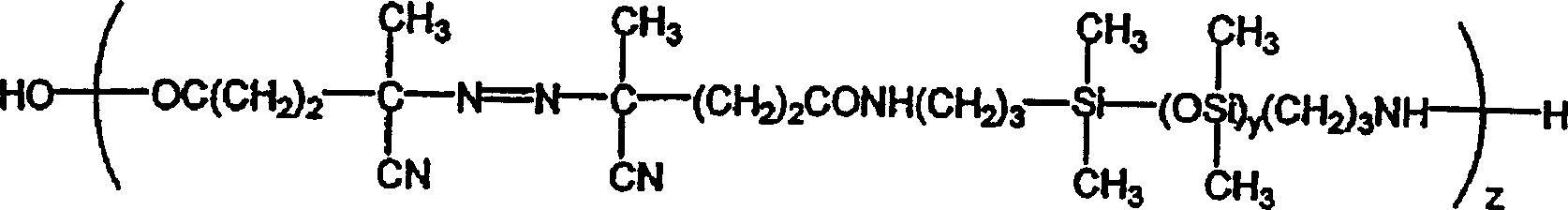

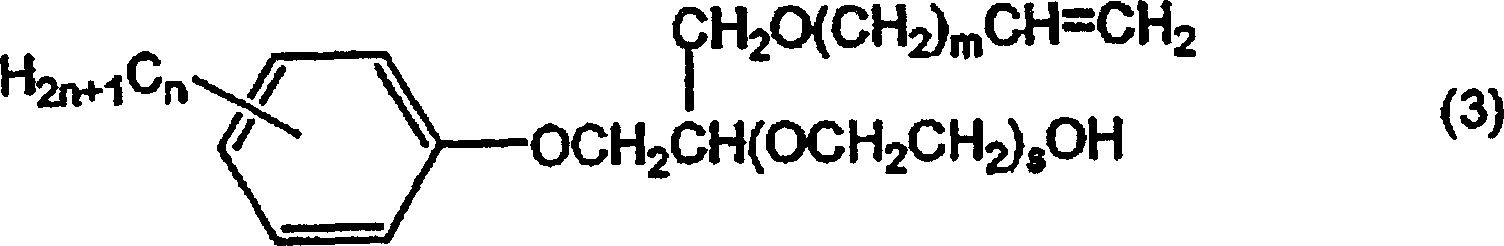

Method used

Image

Examples

manufacture example 1

[0136]Silica coated titanium dioxide particle dispersion (S-1)

[0137] Add 350 parts by weight of titanium oxide micropowder coated with silicon oxide, 80 parts by weight of ethylene oxide-propylene oxide copolymer (average degree of polymerization is about 20), 1000 parts by weight of isopropanol and 1000 parts by weight of butyl cellosolve, The glass beads were dispersed for 10 hours, and the glass beads were removed to obtain 2430 parts by weight of a silica-coated titanium oxide particle dispersion (S-1). Here, the obtained silicon oxide-coated titanium oxide particle dispersion was weighed on an alumina dish, dried on a hot plate at 120° C. for 1 hour, and the total solid content concentration was determined to be 17% by weight. And the titanium oxide particle dispersion-1 coated with silicon oxide was weighed in a porcelain crucible, pre-dried on a hot plate at 80°C for 3 hours, and then fired in a muffle furnace at 750°C for 1 hour, and the obtained inorganic residue ...

manufacture example 2

[0139] Preparation of particles with silica as the main component

[0140] The solid content is 20% by weight, pH 2.7, the specific surface area obtained by the BET method is 226 square meters per gram, and the silanol concentration on the silica particles obtained by the methyl red adsorption method is 4.1×10 -5 Mole / g, water-dispersible colloidal silica (manufactured by Nissan Chemical Industry Co., Ltd., trade name: Snow-Tex) whose metal content in the solvent obtained by the atomic absorption method is Na4.6ppm, Ca0.013ppm, K0.011ppm -O) 30 kilograms are added to the tank, heated to 50 ° C, and the ultrafiltration membrane module (manufactured by トライテツツク) and the alumina ultrafiltration membrane (Nippon Barrier Co., Ltd. Manufactured by the company, trade name: ceramic UF element, specifications: diameter 4 mm, 19 holes, length 1 m, molecular weight cut off = 150,000, membrane area = 0.24 square meters) for concentration. After 0.5 hours, 10 kg of filtrate was discharged,...

manufacture example 3

[0143] Manufacture of silica particle sol

[0144] To 20 kg of methanol-dispersed colloidal silica prepared in Production Example 2, 0.6 kg of trimethylmethoxysilane (manufactured by Toray Douko-ning Co., Ltd.) was added, and stirred under heating at 60° C. for 3 hours. The number-average particle diameter determined by the dynamic light scattering method was 11 nanometers, and no change was found from before the treatment. The resulting methanol-dispersed hydrophobic colloidal silica has a specific surface area of 240 square meters per gram obtained by the BET method, and a silanol concentration of 2.1×10 on the silica particles obtained by the methyl red adsorption method. -5 mol / g.

[0145] After the above process is terminated, add 14 kg of methyl ethyl ketone (MEK), at a temperature of 50°C, a circulation flow rate of 50 liters / min, and a pressure of 1 kg / cm2, use the above-mentioned ultrafiltration membrane to concentrate and discharge 14 kg Filtrate, this operation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com