A method to encapsulate phosphor via chemical vapor deposition

A phosphor and photobody technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve unproven problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

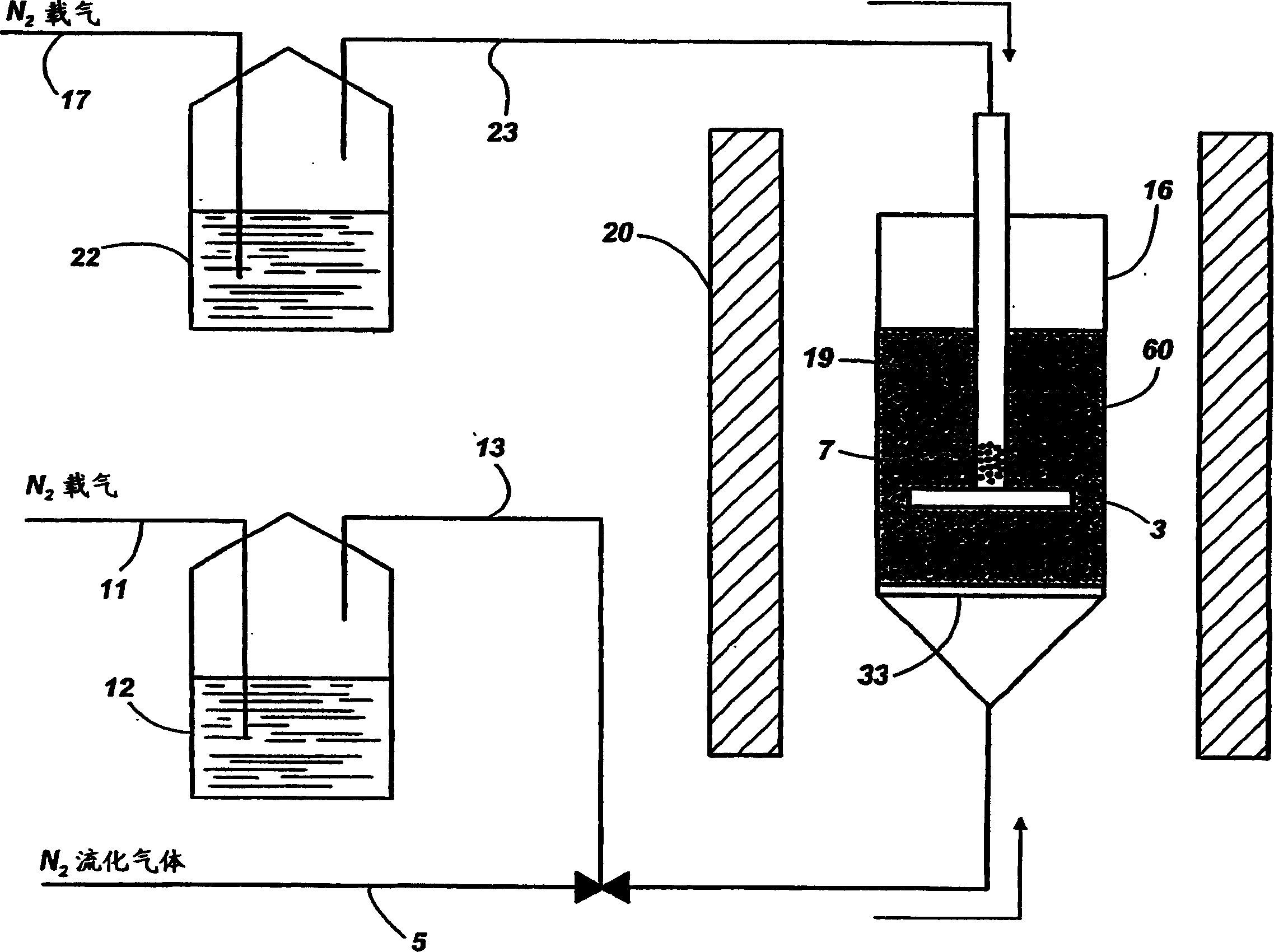

Method used

Image

Examples

experiment example 1

[0019] CBAL and pyrohydrolyzed TMA-coated CBAL (cCBAL) samples were prepared and their emission spectra collected. The samples were then subjected to degradation testing as described above. The application of the pyrohydrolyzed TMA coating significantly improved the retention characteristics of the CBAL phosphor. Optical emission results for the original and degraded CBAL and cCBAL phosphors are provided in Table 1 below (compared to the standard BAM phosphor used for comparison). The term "TH" refers to samples degraded by exposure to high temperature and humidity; the term "X" refers to samples degraded by exposure to high-intensity xenon plasma and VUV photon flux; the term "THX" refers to Samples degraded by exposure to high temperature and humidity followed by exposure to high intensity xenon plasma and VUV photon flux. Measure the intensity of the blue-emitting PDP BAM phosphor relative to a standard.

[0020] Powder Plate Data

[0021] The degradation res...

Embodiment 2

[0023] Manganese-activated zinc silicate (Zn 2 SiO 4 : Mn) is a high-efficiency green light-emitting phosphor for plasma display panels. The phosphor is very stable during the PDP panel production process. Significant brightness deterioration and color shift were not observed after exposure to high temperature and high humidity. However, the phosphor brightness deteriorates significantly under ion bombardment and plasma VUV irradiation. In order to improve brightness retention, according to the method of the present invention, Zn is coated with aluminum hydroxide coating 2 SiO 4 : Mn phosphor (OSRAMSYLVANIA type 9310). To compare the effect of hydrolyzed TMA coatings under accelerated aging test conditions, phosphor powders were encapsulated at low (180°C) and high (430°C) reaction temperatures. Uncoated and coated phosphors were mixed with the paste and the binder burned off (BBO). Initial brightness (after BBO) and final brightness (after exposure to high intensity Xe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com