Extractive of phytosterol extracted from bamboo shoot, preparation method and application

A technology of bamboo shoot sterols and extracts, which is applied in the field of deep processing and comprehensive utilization of agricultural and sideline products, and can solve the problems of little understanding of the components and functions of bamboo shoots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

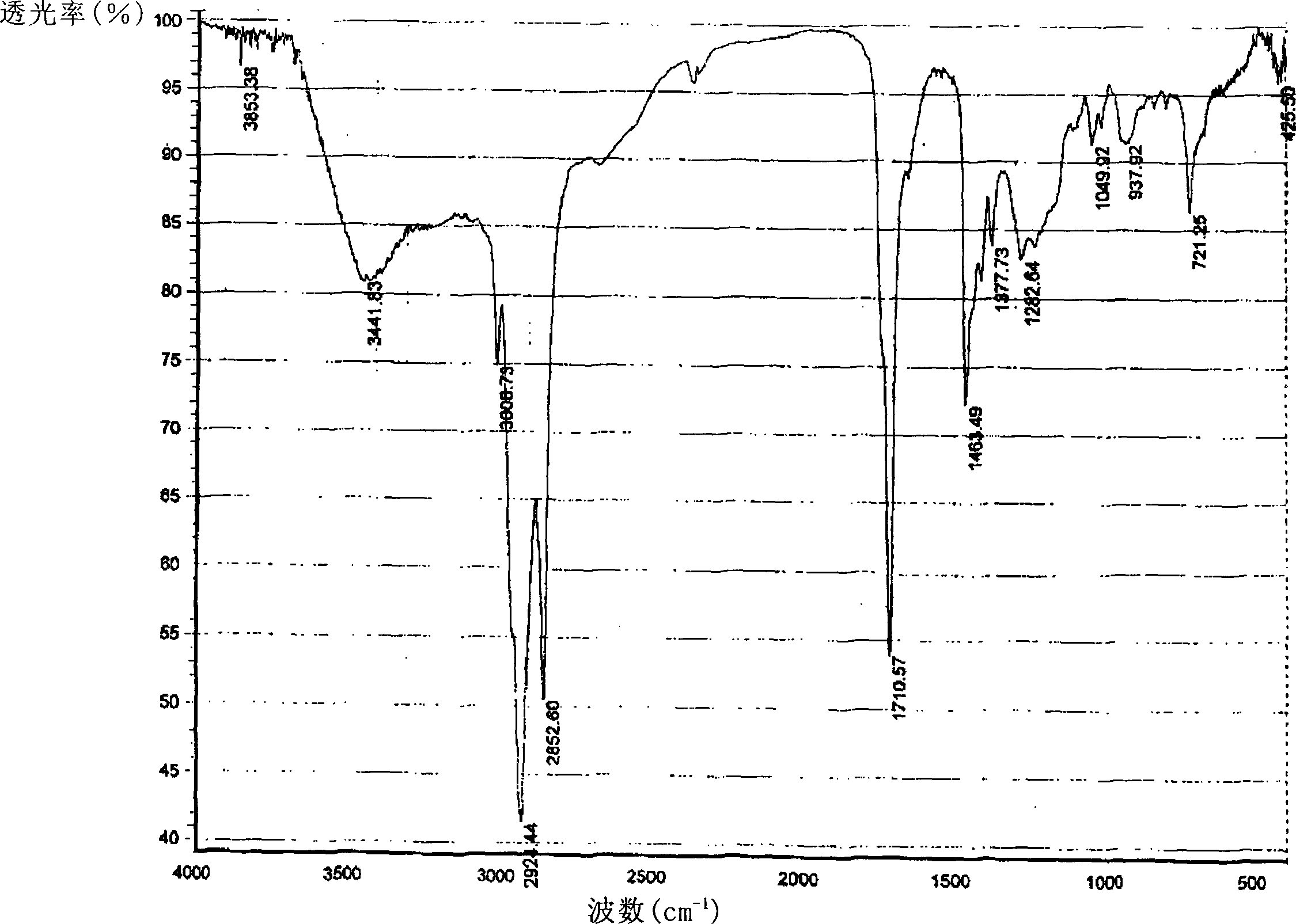

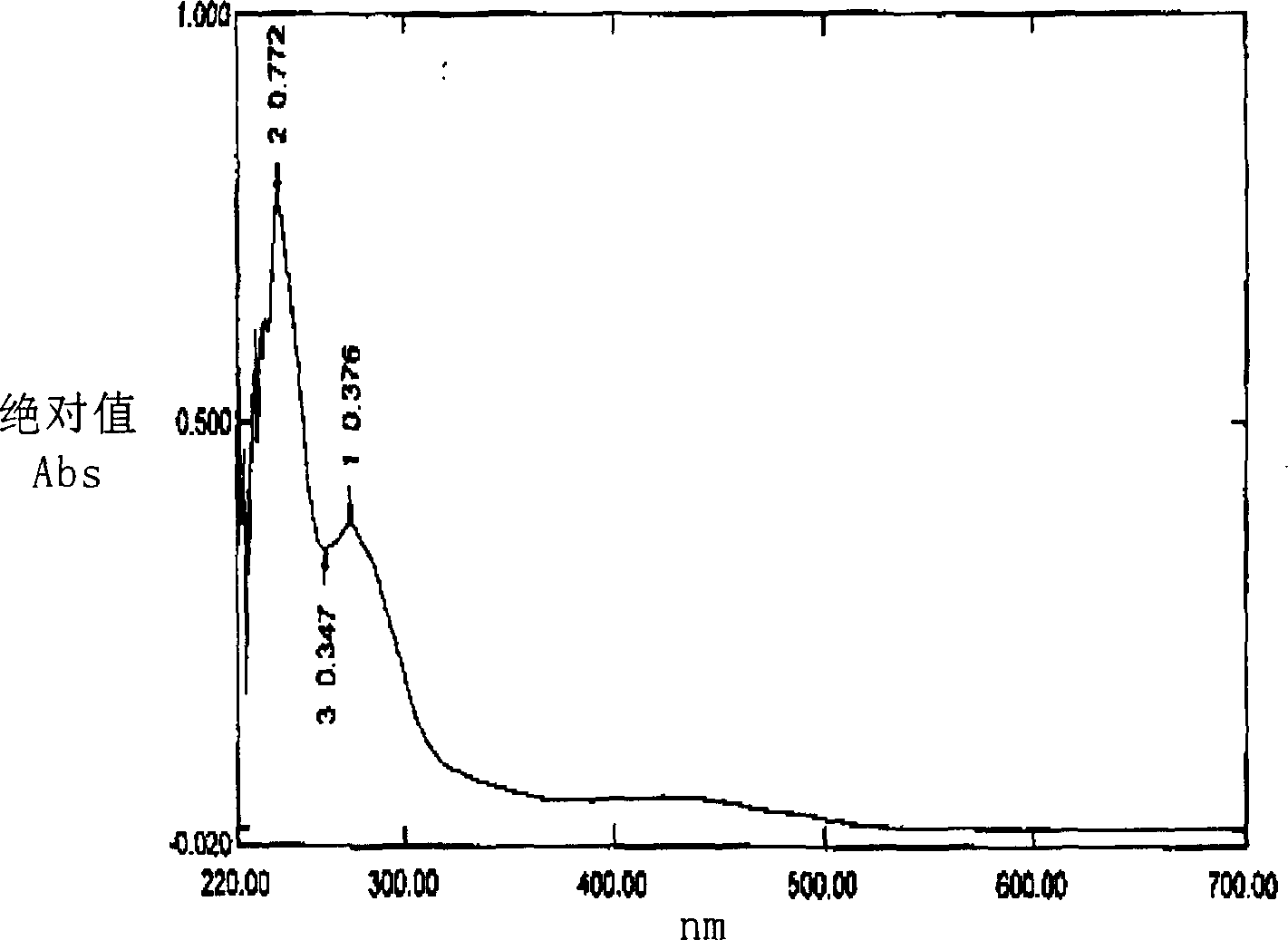

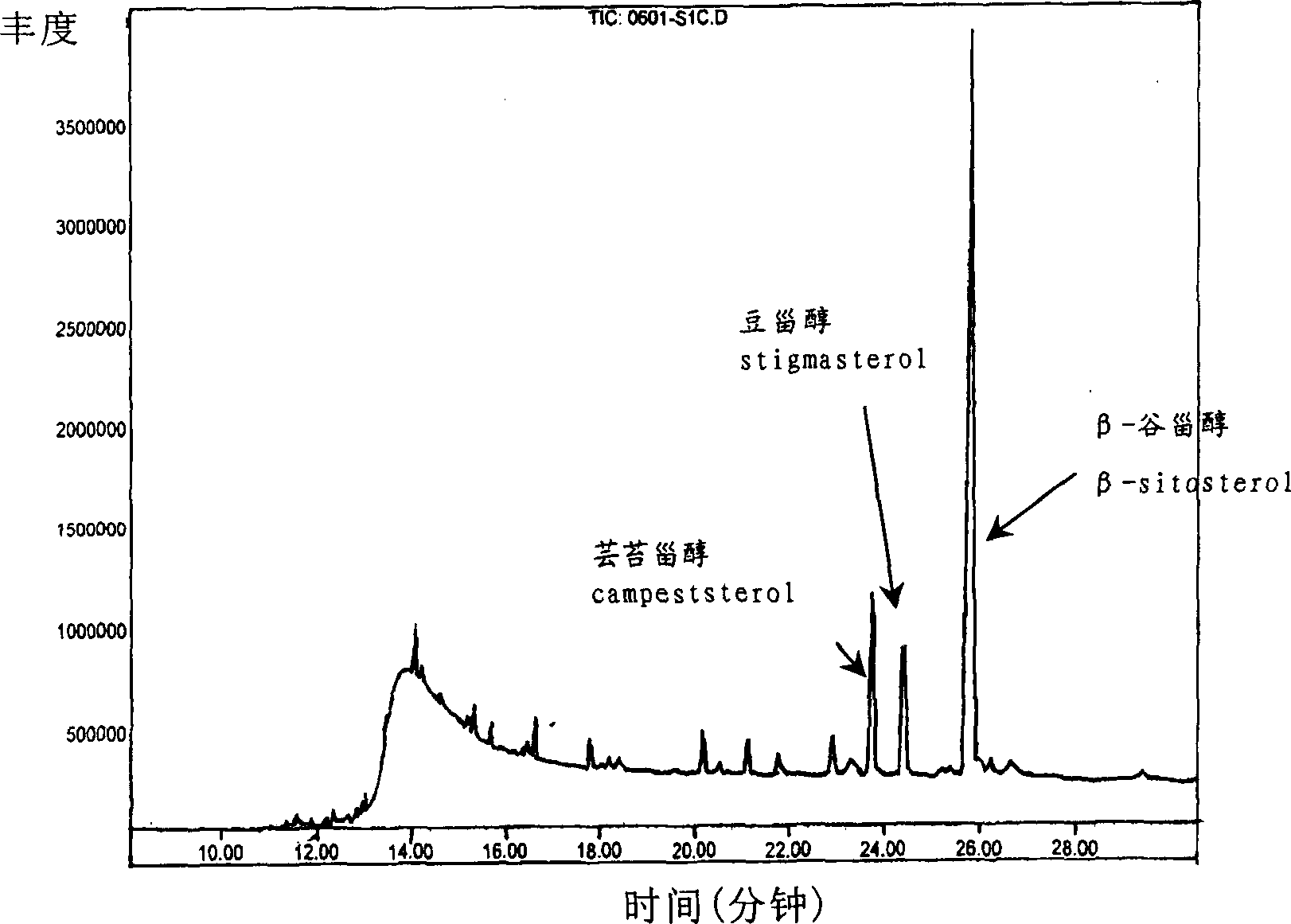

Embodiment 1

[0054] After peeling the moso bamboo shoots, the bamboo shoots are beaten into a pulp, after squeezed to remove water, dried to a certain extent, and then dried with a microwave to a moisture content of 5%, crushed into 5kg of 20 mesh bamboo husk powder, and put it Put it into the supercritical extraction kettle, heat up to 50℃, start the plunger pump to pump CO 2 , Enter the extraction kettle through the preheater, when the pressure reaches 25MPa, start the cycle; turn on the entrainer pump, so that 10% of the raw material weight ethanol enters the extraction kettle at the same time after passing through the preheater; during the cycle, CO 2 And the extract is decompressed in the separator, the extract is separated out in the separator, and the CO 2 Recycling, separation kettle 1 set separation pressure 8MPa, temperature 40℃, separation kettle 2 set separation pressure 5MPa, temperature 30℃; after 4h extraction, take out 50g extract from separation kettle 1 and 2 to get The rate ...

Embodiment 2

[0062] The husks of the bamboo shoots are sun-dried to a certain extent and then dried with hot air to a moisture content of 5%, crushed into 5kg of 20 mesh bamboo husk powder, and put into the supercritical extraction kettle, heated to 60℃, and activated the plunger pump Pump CO 2 , Enter the extraction kettle through the preheater, and when the pressure reaches 30MPa, the cycle begins; turn on the entrainer pump, so that 10% by volume of acetone enters the extraction kettle at the same time after passing through the preheater; during the cycle, CO 2 And the extract is decompressed in the separator, the extract is separated out in the separator, and the CO 2 Recycling, separation tank 1 is set to separate pressure 8MPa, temperature is 45℃, separation tank 2 is set to separate pressure 5MPa, temperature is 30℃; after 2.5h extraction, 40g of extract is taken out of separation tank 1 and 2, The yield was 0.8%. After low-temperature drying, the bamboo shoot sterol extract was obtaine...

Embodiment 3

[0065] The bamboo shoot heads are sliced and beaten into a pulp. After squeezing to remove water, they are dried to a certain extent, dried with a microwave to a moisture content of 5%, crushed into 20 mesh bamboo shoots powder 6kg, and put it into the supercritical extraction kettle In the middle, the temperature is raised to 45℃, and the plunger is pumped into CO 2 , Enter the extraction kettle through the preheater, when the pressure reaches 20MPa, the cycle starts; during the cycle, CO 2 And the extract is decompressed in the separator, the extract is separated out in the separator, and the CO 2 Recycling, separation tank 1 is set to separate pressure of 6MPa, temperature is 35 ℃, separation tank 2 is set to separate pressure of 5 MPa, temperature is 30 ℃; after extraction for 1 hour, take out 60g of the extract from separation tanks 1 and 2 to obtain The rate was 1.0%. After low-temperature drying, the bamboo shoot sterol extract was obtained; the machine was stopped and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com