Method for preparing lithium ion battery anode material lithium ion phosphate

A lithium-ion battery, lithium iron phosphate technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve problems such as unsuitable industrial production, expensive LiI, etc., achieve easy product formulation, improve product purity, and cycle performance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

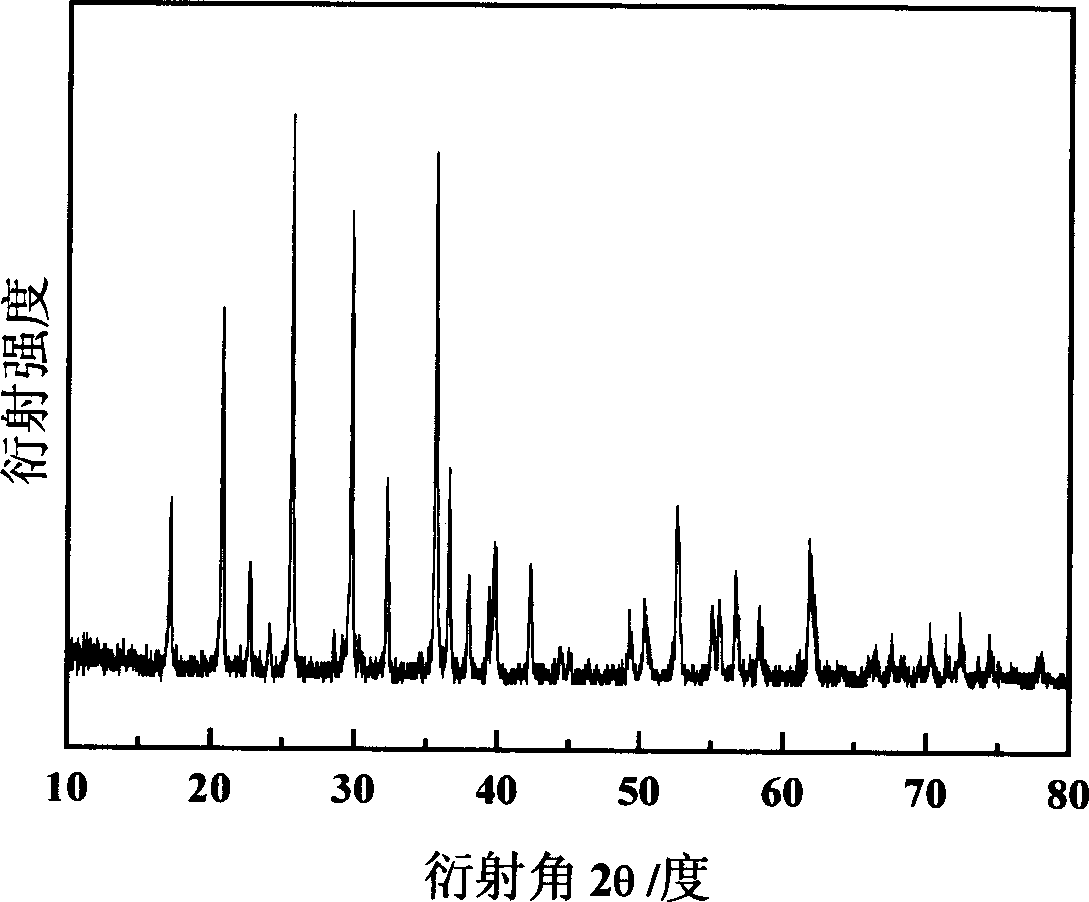

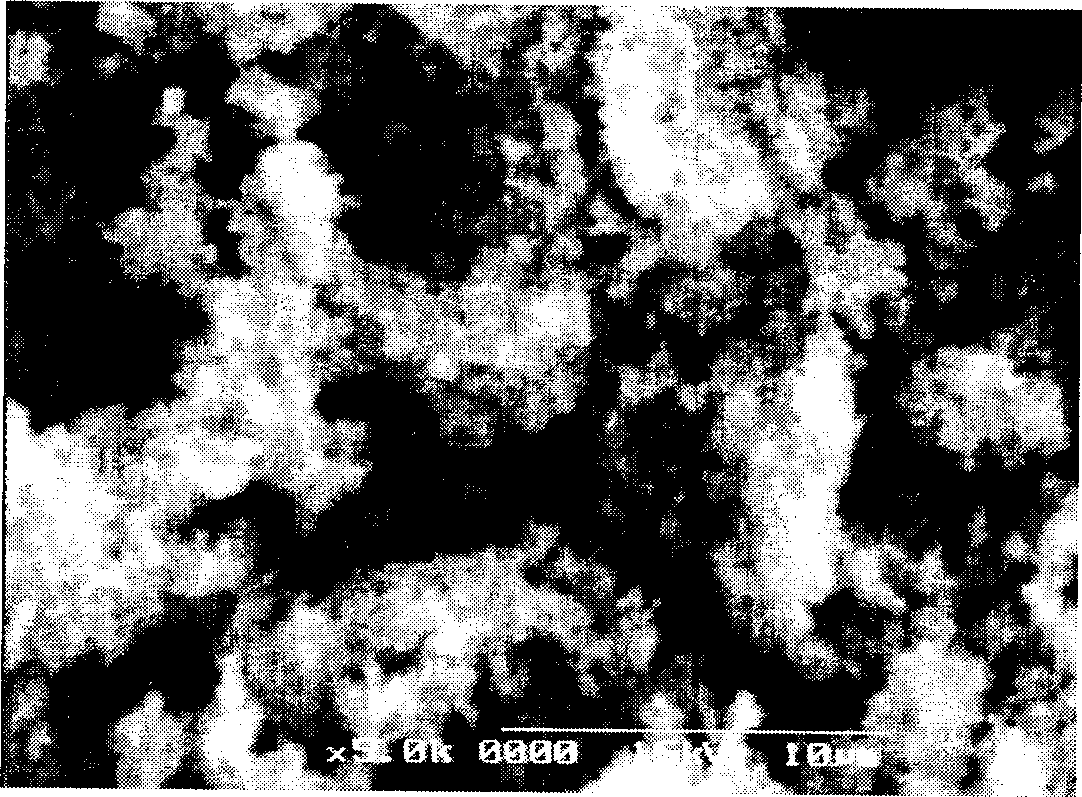

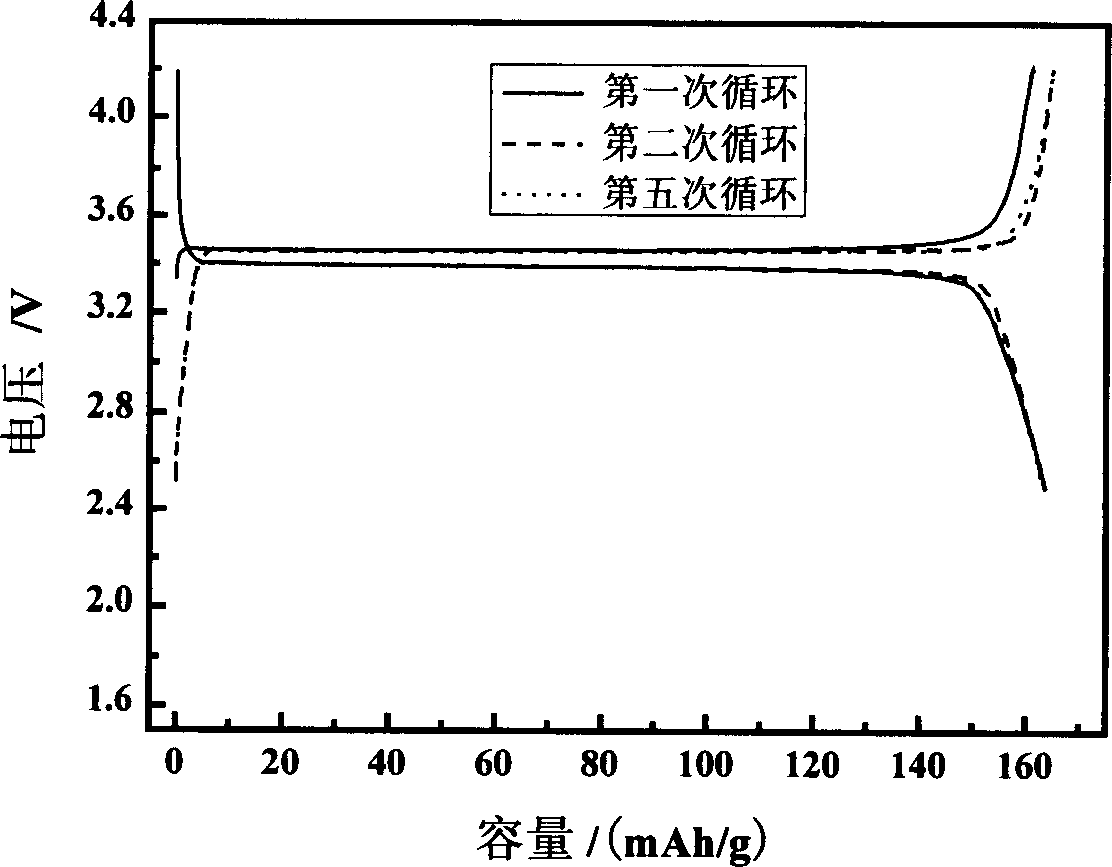

[0023] Weigh 0.01molFe(NH 4 ) 2 (SO 4 ) 2 ·6H 2 O and 0.01mol NH 4 h 2 PO 4 Dissolve in 500ml of deionized water respectively, after mixing the two solutions, add 4mL of 30% H 2 o 2 aqueous solution, stirring was continued for 2 hours. The resulting precipitate was filtered, washed and dried to obtain FePO 4 . 0.02molLiAc·2H 2 O, 0.01mol FePO 4 , 0.01mol ascorbic acid was mixed in 50mL ethanol, stirred and reacted for 10 hours, the solvent was volatilized at 60° C. and the obtained amorphous lithium iron phosphate precipitate was washed, and then the amorphous lithium iron phosphate precipitate was placed in a high-temperature furnace, in a mixed atmosphere ( 95%Ar+5%H 2 ), heating at a heating rate of 5°C / min, roasting at a constant temperature of 600°C for 2 hours, and then cooling to room temperature at a cooling rate of 20°C / min, to obtain lithium iron phosphate powder, a cathode material for lithium-ion batteries in crystal form. figure 1 It is an X-ray diff...

Embodiment 2

[0027] Weigh 0.01molLiAc·2H 2 O, 0.01mol FePO 4 (prepared according to Example 1), 0.005 mol of ascorbic acid was dissolved in 25 mL of ethanol, stirred and reacted for 20 hours, the solvent was evaporated at 60° C. and the obtained lithium iron phosphate precipitate was washed, and finally the lithium iron phosphate precipitate was placed in a high-temperature furnace and heated under argon gas. Raise the temperature at a heating rate of 5°C / min in the atmosphere, bake at a constant temperature of 700°C for 10 hours, and then cool to room temperature at a cooling rate of 10°C / min to obtain lithium iron phosphate powder, a cathode material for lithium-ion batteries. The discharge specific capacity of this material is about 130mAh / g.

Embodiment 3

[0029] Weigh 0.01molLiAc·2H 2 O, 0.01mol FePO 4 (prepared according to Example 1), 0.01mol ascorbic acid was dissolved in 25mL ethanol, after stirring for 20 hours, the precipitate was filtered, washed, dried, and then in a mixed atmosphere (95%Ar+5%H 2 ) at a heating rate of 5 °C / min, roasted at a constant temperature of 650 °C for 15 hours, and then cooled to room temperature at a cooling rate of 10 °C / min to obtain lithium iron phosphate powder, a cathode material for lithium-ion batteries. The discharge specific capacity of this material is about 140mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reversible specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com