Circulating type aerobe reactor for treating organic waste

An aerobic biological and organic wastewater technology, applied in the direction of water pollutants, sustainable biological treatment, biological water/sewage treatment, etc., can solve mass transfer efficiency, operation management load and energy consumption defects, blowers and other aeration equipment Oxygenation efficiency is low, increase the design volume of sewage treatment structures, etc., to achieve stable treatment effect, increase reproduction, and high volume load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

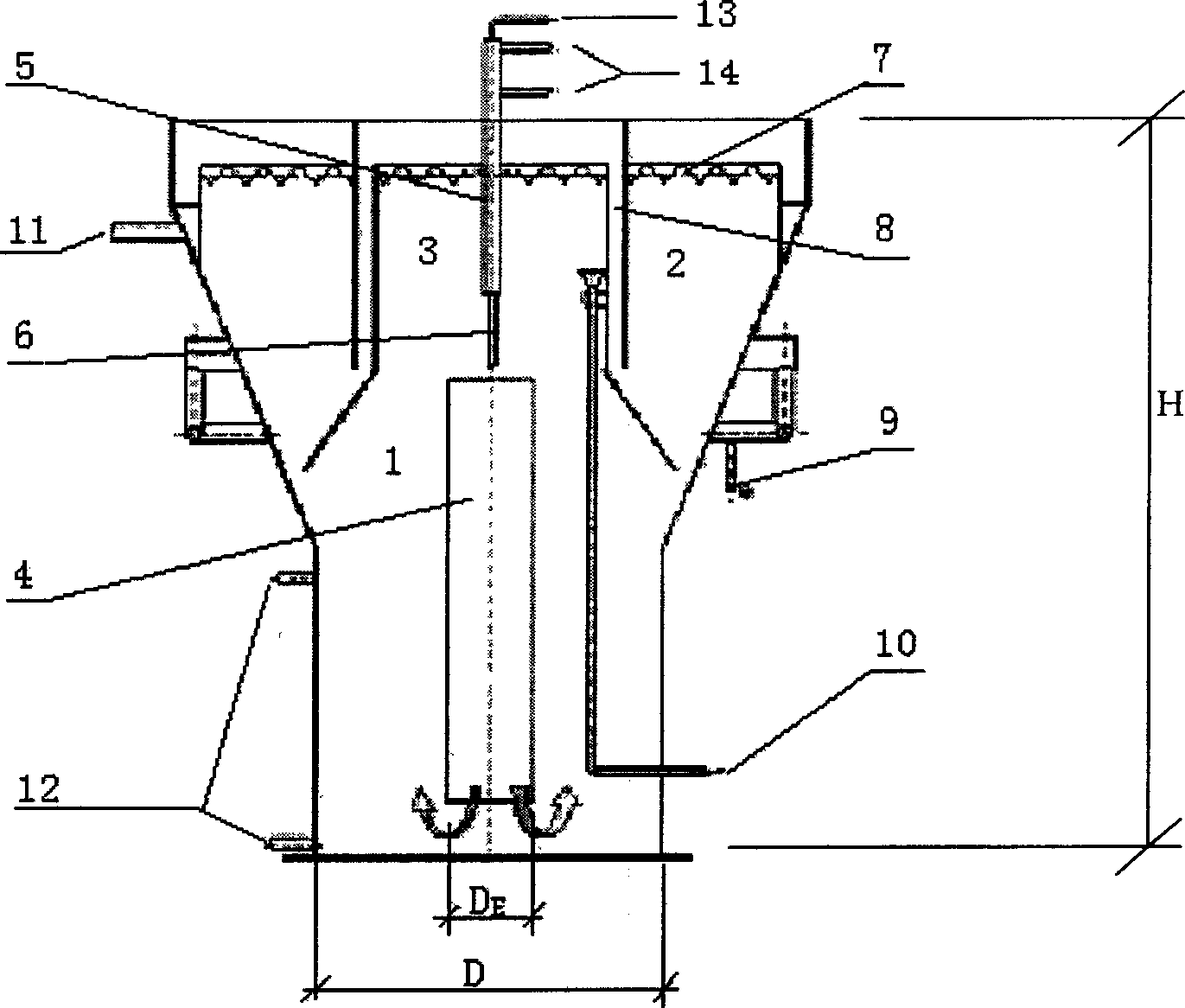

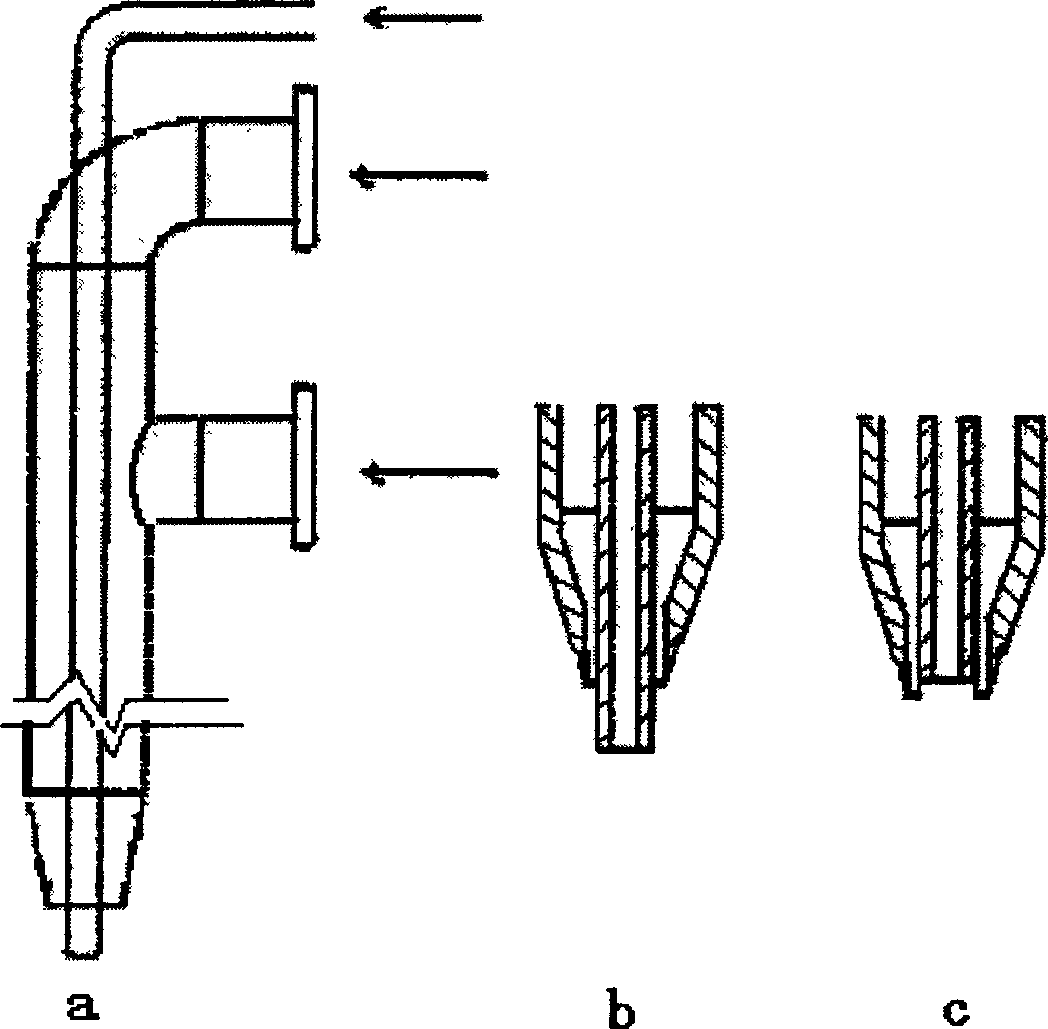

Method used

Image

Examples

Embodiment 1

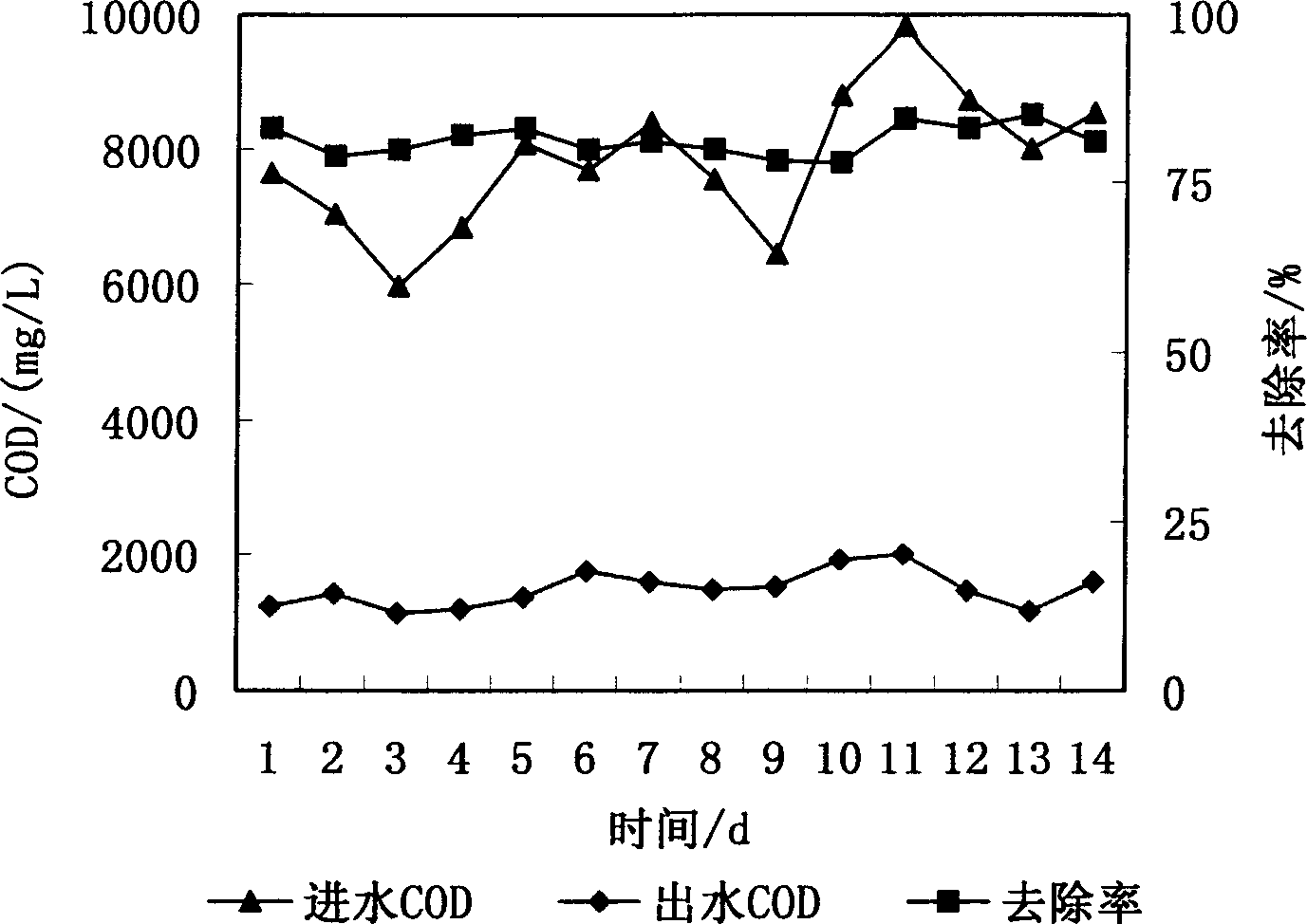

[0025] Embodiment 1: JLCR to the removal rate of COD

[0026] The most important indicator of organic pollutants in wastewater is chemical oxygen demand (COD). High-intensity aerobic bioreactors should have a high removal effect on COD in wastewater. image 3 is the removal rate profile for the JLCR run. Influent COD Cr The concentration is about 8000mg / L, the removal rate is above 75%, and the effluent COD Cr Relatively stable.

[0027] COD of water inflow during operation Cr There are some fluctuations, the lowest value is 5969mg / L, the highest value is 9847mg / L, the removal rate has a slight change correspondingly, the removal rate is maintained above 75%, and the removal effect is good.

Embodiment 2

[0028] Embodiment 2: the contrast of activated sludge oxygen utilization rate in the activated sludge in JLCR reactor and SBR

[0029] The temperature is 21°C and the sludge concentration is 2000mg / L. Figure 4It is the result of a comparative test of the oxygen utilization rate of the activated sludge in the JLCR reactor and the activated sludge in the SBR, carried out under the same experimental conditions. It can be seen from the figure that the oxygen utilization rate curve of the activated sludge in the JLCR reactor has a larger slope than the oxygen utilization curve of the SBR sludge, indicating that the oxygen utilization rate of the former is greater than that of the latter. After linear fitting, the oxygen utilization rates of the two are calculated to be 46.2mgO2 / L h and 26.8mgO2 / L h respectively. The test results show that the activated sludge in the JLCR reactor has a high activity and is resistant to pollutants. The decomposition and utilization rate is faster t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com