Method of degrading Napolean green in waste water

A malachite green and wastewater technology, applied in chemical instruments and methods, water/sewage treatment, light water/sewage treatment, etc., can solve the problems of water consumption, large equipment and area, poor degradation effect, etc. Saving capital investment, less floor space, good degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

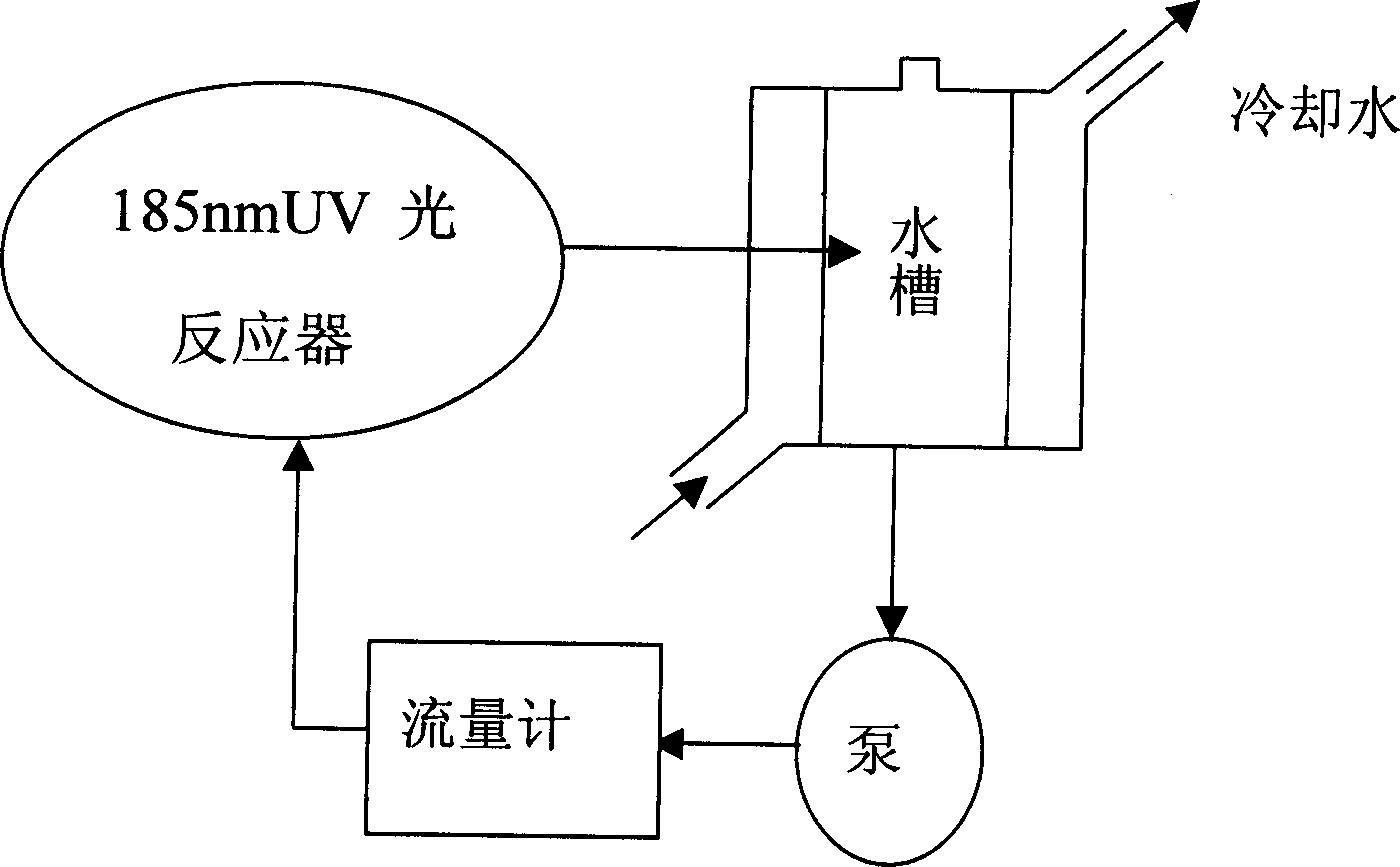

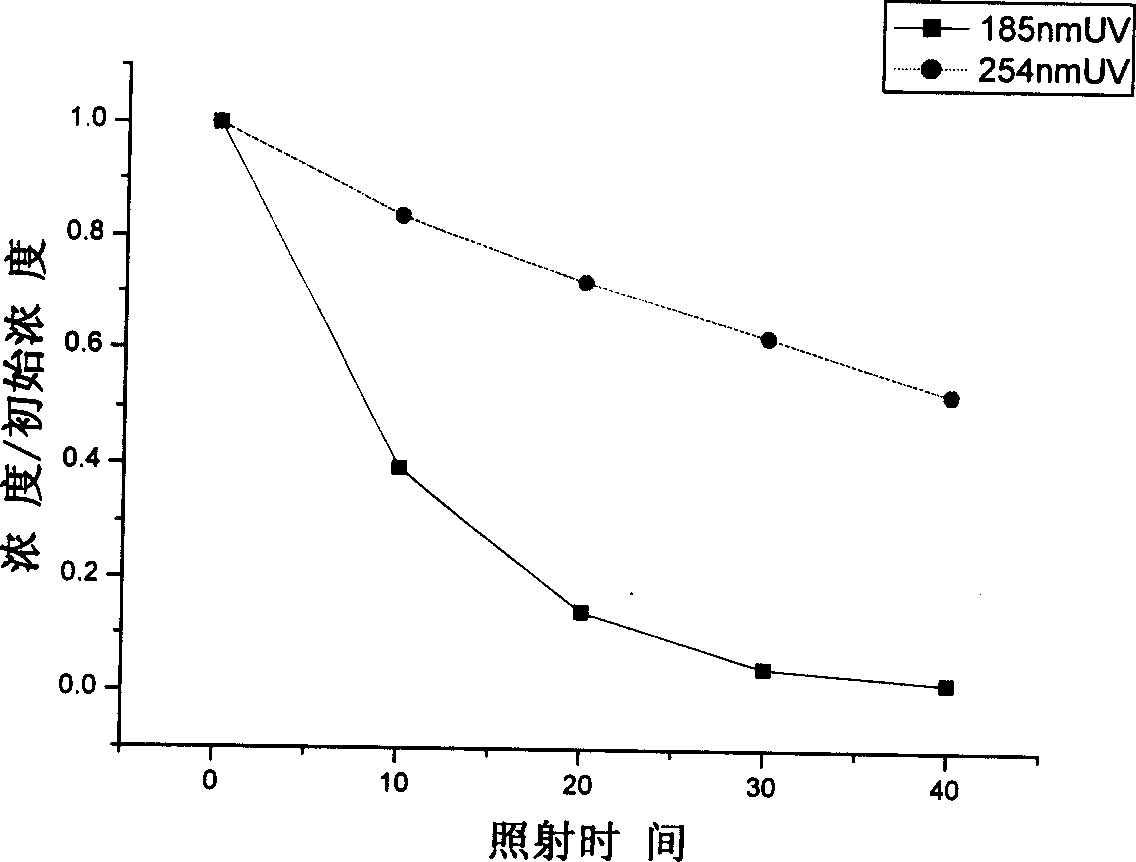

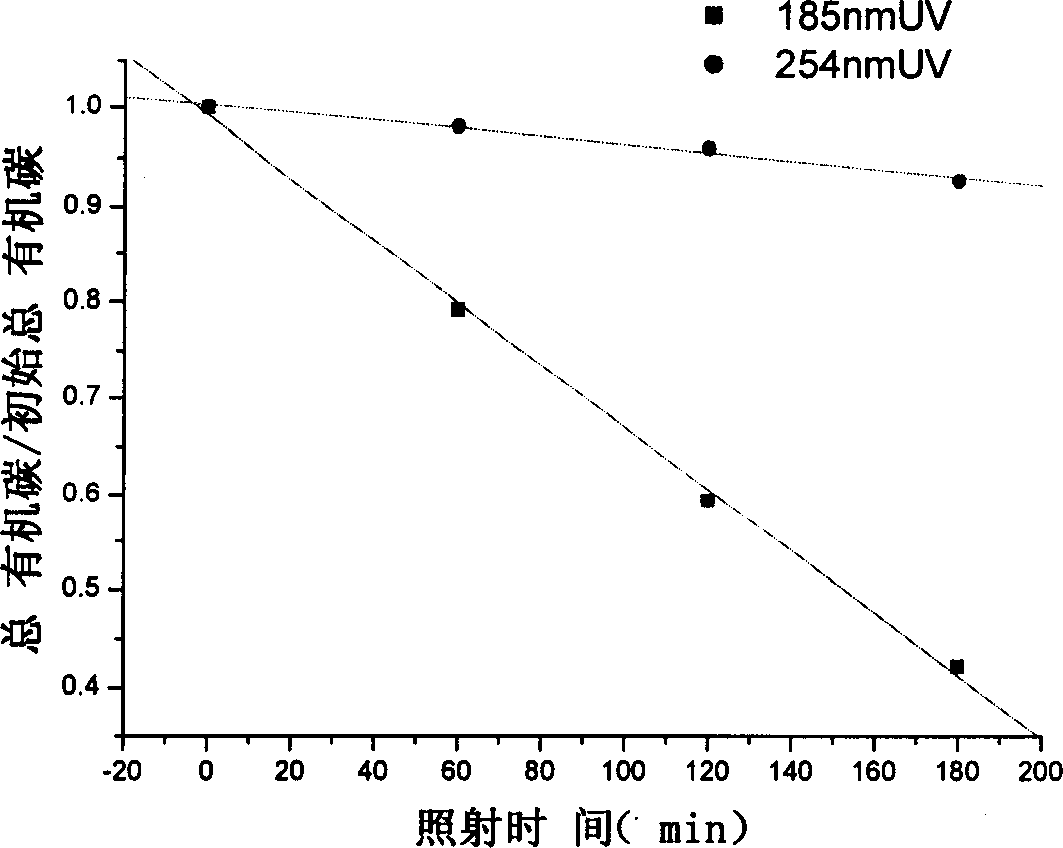

[0023] see figure 1 , first at room temperature, the malachite green-containing waste water is added to the water tank, and then according to the flow rate displayed on the flowmeter is 0.14 ~ 0.70L / min, pumped into a commercially available 185nmUV lamp (intensity: 1.04×10 -5 einstein / s, voltage 220V, current 0.42A) in the reactor. Then pump the malachite green wastewater after the 185nmUV reaction back into the water tank, and circulate it at a flow rate of 40-160L / h, then take out the water sample from the water tank to measure the malachite green concentration, and the results show that the malachite green treated by the process of the present invention Wastewater can be degraded from 10mg / L to 0 in about 40 minutes, and the degradation rate reaches over 99%.

[0024] The photoreactor loaded with 185nmUV lamp consists of a stainless steel cavity (length: 28.30cm; outer diameter: 6.37cm; inner diameter: 5.97cm; total volume: 791ml) and a 185nmUV low-pressure mercury lamp (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com