Organic nano paint of nano mesoporous silicon dioxide particle and its preparing method

A technology of silica and nano-mesoporous, applied in the direction of epoxy resin coating, coating, etc., to achieve the effect of low industrial application cost, low addition amount, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

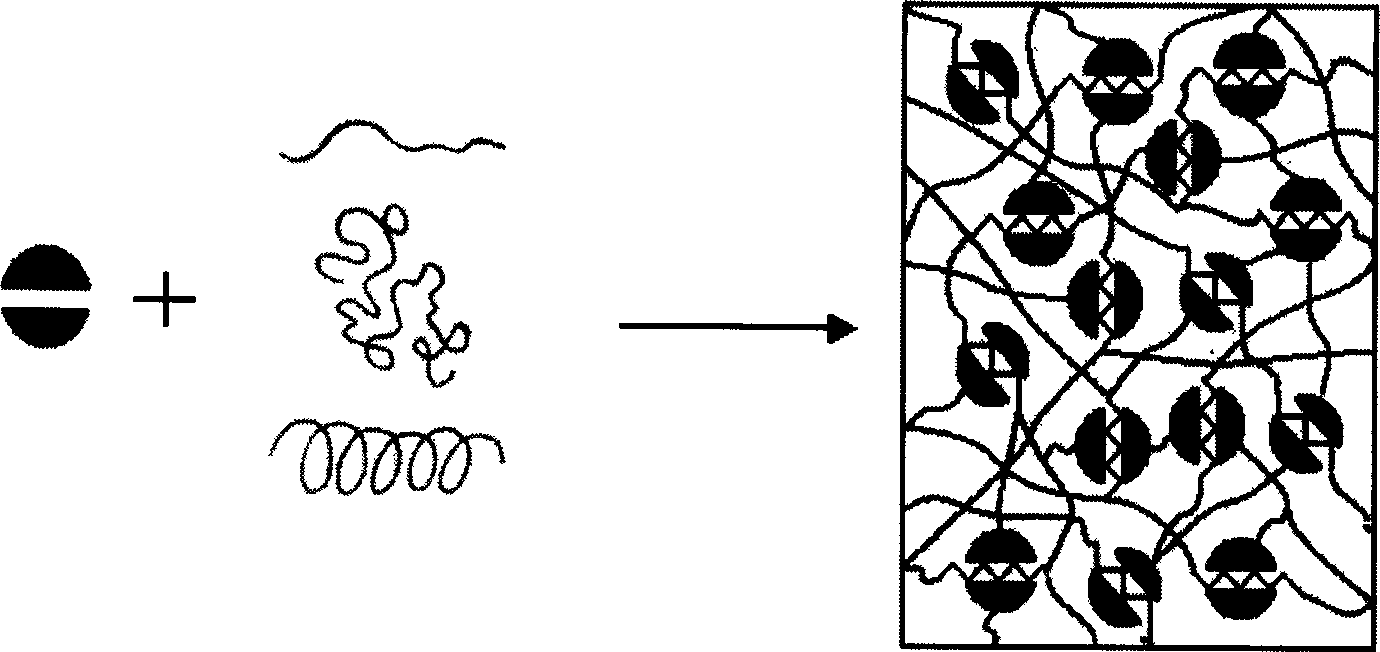

[0048] The synthesis of nano-mesoporous silica particles adopts the sol-gel method, and the specific implementation method Figure 2a-Figure 2d The transmission electron microscope photo shows monodisperse uniform spherical particles, the spectrum shows an ordered hexagonal mesoporous structure, the particle size is 60-80nm, the pore size is 3-4nm, and the specific surface area is 732m 2 / g or so, the pore volume is 0.86cm3 / g.

[0049] Among them: nanometer mesoporous silica silane coupling agent modification method:

[0050] Ingredients (percentage by weight):

[0051] Silane coupling agent 2%;

[0052] Nano Mesoporous Silica Particles 28%

[0053] n-Hexane 70%;

[0054] The modified nano-mesoporous silica particles are introduced into the inner pores and outer surfaces of the nano-mesoporous silica particles that can interact with epoxy groups (through the alkoxysilane group in the silane coupling agent) It is easy to biochemically react with the hydroxyl group in the ...

Embodiment 2

[0057] Coating Formulation:

[0058] Modified nano-mesoporous silica particles and nano-mesoporous silica particles: 2.5% (particle size is 60-80nm);

[0059] Dispersant: 0.5%;

[0060] Dibutyl phthalate: 5%;

[0061] Xylene: n-butanol=7: 3 20%;

[0062] Epoxy resin (using E-44): balance.

[0063] Its dispersant composition (percentage by weight):

[0064] Sodium Oleate 10%;

[0065] Disperbyk-160 (acrylic acid copolymer ammonium salt) 80%;

[0066] Toluene 10%

[0067] The dispersant is prepared by first mixing sodium oleate and toluene at 25°C and 1 atm to fully dissolve the sodium oleate in toluene, then slowly adding the Disperbyk-160 component and mixing evenly.

[0068] Coating preparation method:

[0069] Weigh 2.5% of nanometer mesoporous silica powder, nanometer mesoporous silica powder modified by silane coupling agent, mix them with dispersant evenly, and add them into the epoxy resin mixed with other additives , and then grind and disperse at room temperat...

Embodiment 3

[0073] Difference with embodiment 2 is that coating formula:

[0074] Modified nano-mesoporous silica particles and nano-mesoporous silica particles 5% (particle size 80-100nm);

[0075] Dispersant: 1%;

[0076] Dibutyl phthalate: 5%;

[0077] Xylene: n-butanol=7: 3 5%;

[0078] Epoxy resin (using 6458): balance.

[0079] Among them: nanometer mesoporous silica silane coupling agent modification method:

[0080] Ingredients (percentage by weight):

[0081] Silane coupling agent 5%;

[0082] Nano-mesoporous silica particles 28%;

[0083] Deionized water 67%;

[0084] The difference in the preparation of the modified nanoparticles is: slowly pour the nanometer mesoporous silica powder into deionized water, reflux and stir, and at the same time raise the temperature to 65°C, drop the silane coupling agent solution into the three-necked bottle, After the dropwise addition is completed, keep warm and continue to stir for 7 hours; after the reaction is completed, wash the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com