Method of producing zinc phosphate using phosphorus fertilizer

A technology of zinc phosphate and wet zinc phosphate, which is applied in the direction of phosphate, phosphorus oxyacid, etc., can solve the problems of high production cost, low purity, and high impurity content in products, and achieve the effects of low production cost, wide sources, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

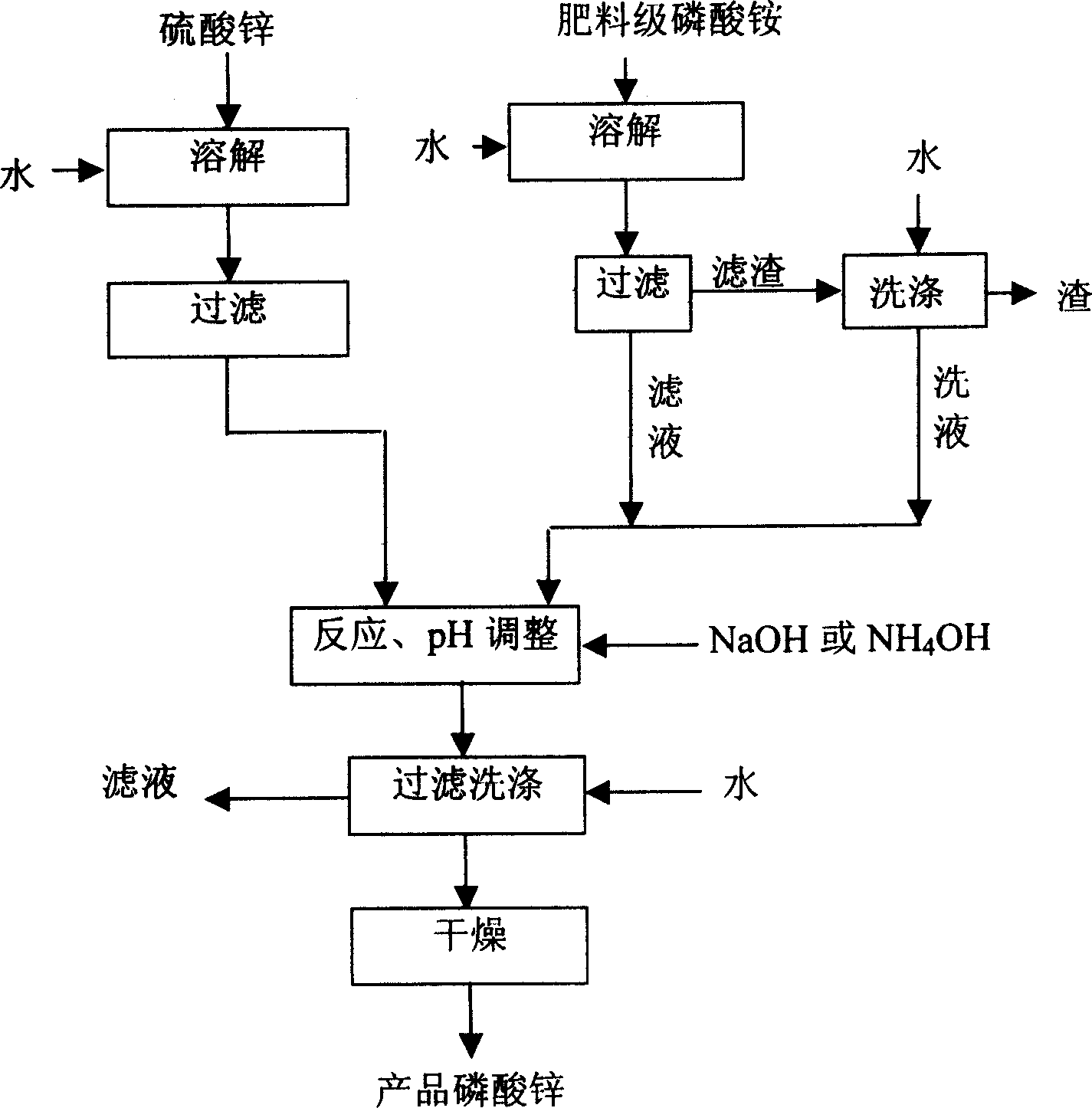

Method used

Image

Examples

Embodiment 1

[0034] Dissolve 1.25kg of fertilizer-grade diammonium phosphate into 1.5kg of hot water at 75°C under stirring, keep the temperature at 75°C, filter after 35 minutes, wash the filter residue once with hot water at 70°C, and combine the washing liquid with the filtrate; 2.6kg of sulfuric acid Zinc (ZnSO 4 ·7H 2 O) be dissolved in 2.0kg, the zinc salt solution that makes in 70 ℃ of hot water, through filtering; Adjust the pH value to 6.8 with sodium hydroxide, and filter the reaction solution after maintaining the temperature for 20 minutes; wash the filter cake with 3 times its weight in hot water at 70°C for 3 times to obtain a zinc phosphate wet filter cake; under normal pressure, at 110°C Dry for 20 minutes to obtain the product zinc phosphate. The analysis results are shown in Table 1:

[0035] Zn,%

[0036] The product obtained above is Zn 3 (PO 4 ) 2 2H 2 O.

Embodiment 2

[0038] Dissolve 3kg of fertilizer grade monoammonium phosphate into 3.5kg of hot water at 75°C under stirring, keep at 75°C for 35 minutes and filter, wash the filter residue twice with hot water at 60°C, and combine the washing liquid with the filtrate; 7kg of zinc sulfate (ZnSO 4 ·7H 2 0) be dissolved in 5kg, 70-80 sense ℃ of hot water and filter and make the zinc salt solution of 45wt%, filter; Above-mentioned two kinds of solutions join in a stirred reactor simultaneously, and reaction temperature keeps 70-80 ℃, and solution adds Finally, adjust the pH value with 40wt% sodium hydroxide to be 7.2-8, and then filter the reactant after maintaining the temperature for 18 minutes; the filter cake is washed twice with 4 times its weight in hot water at 80°C to obtain a zinc phosphate wet filter cake; Under normal pressure, dry at 110°C for 18 minutes to obtain the product zinc phosphate. The analysis results are shown in Table 2:

[0039] Zn,%

[0040] The product ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com