Method of preparing octadecyl type integral liquid chromatography micro-column

An octadecyl-type, liquid chromatography technology, which is applied in the field of preparation of octadecyl-type monolithic liquid chromatography microcolumns, can solve the problems of difficult preparation of filter sieve plates and low success rate, and achieve permeability Good, fast analysis speed, low column pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Cleaning and activation treatment of the inner wall of the capillary: Take a fused silica capillary with an inner diameter of 530 μm and a length of 3 m, first wash it with acetone for 30 minutes, and then use 1mol L -1After washing with NaOH for 30min, rinse with secondary water to neutrality, and then use 0.1mol L -1 Rinse with HCl at a temperature of 70°C for 2 hours, rinse with water twice to neutrality, place in a gas chromatographic column thermostat, blow nitrogen slowly at 160°C overnight, and then seal both ends and store in a desiccator.

[0036] 2) Pre-polymerization of the inner wall of the capillary: take 2.0mL of γ-methacrylic acid oxypropyl trimethoxysilane (γ-MAPS) and add 10 μL of dry acetic acid, nitrogen and ultrasonic vibration for 10min, and then inject it into the pretreated capillary Inside, both ends were sealed, placed in an oven at 60°C for 20 hours, and the remaining reaction liquid was flushed out with acetone, and then nitrogen was blown ...

Embodiment 2

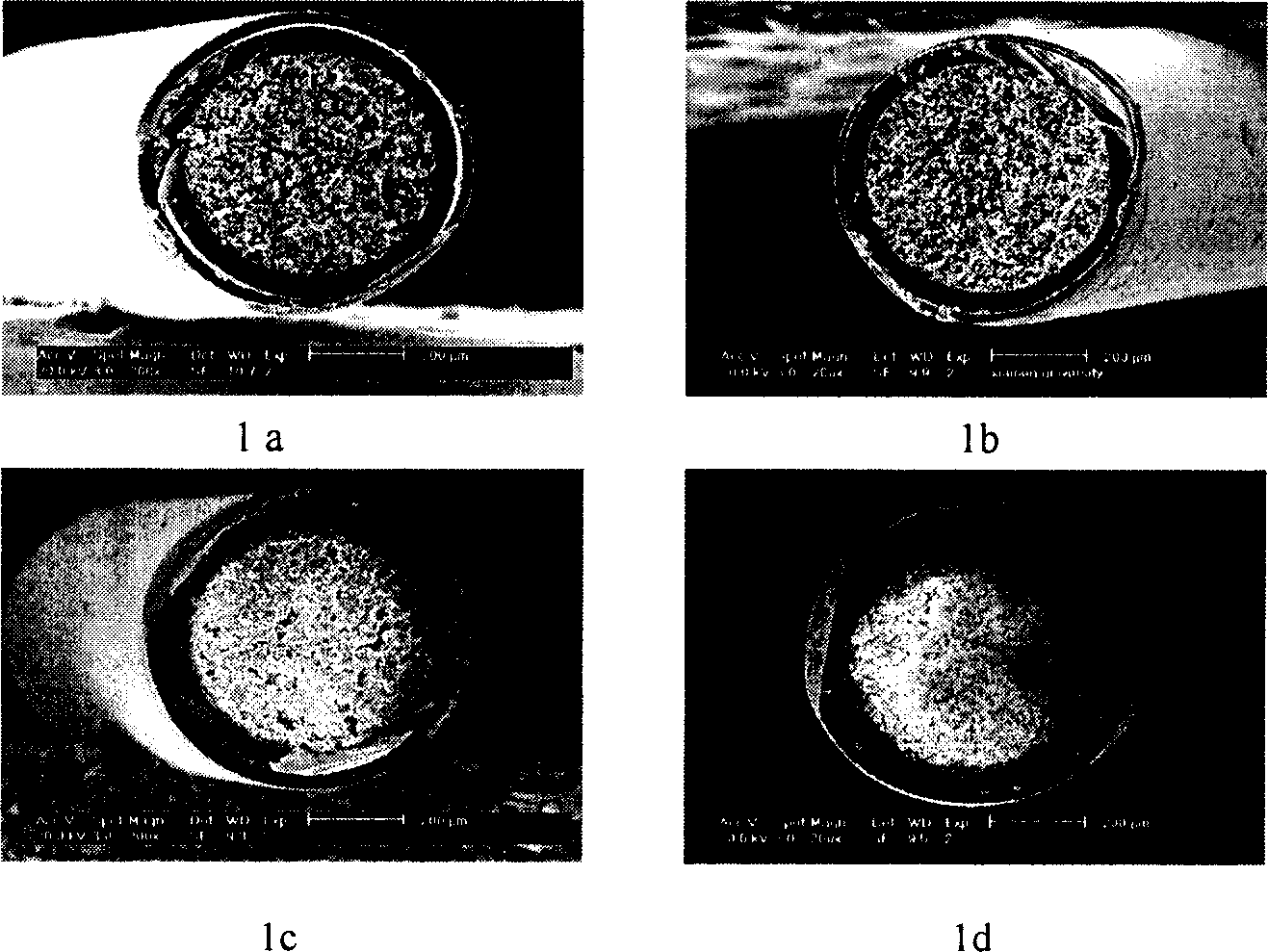

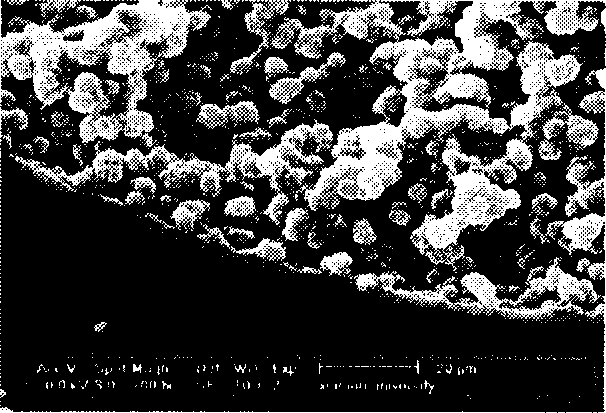

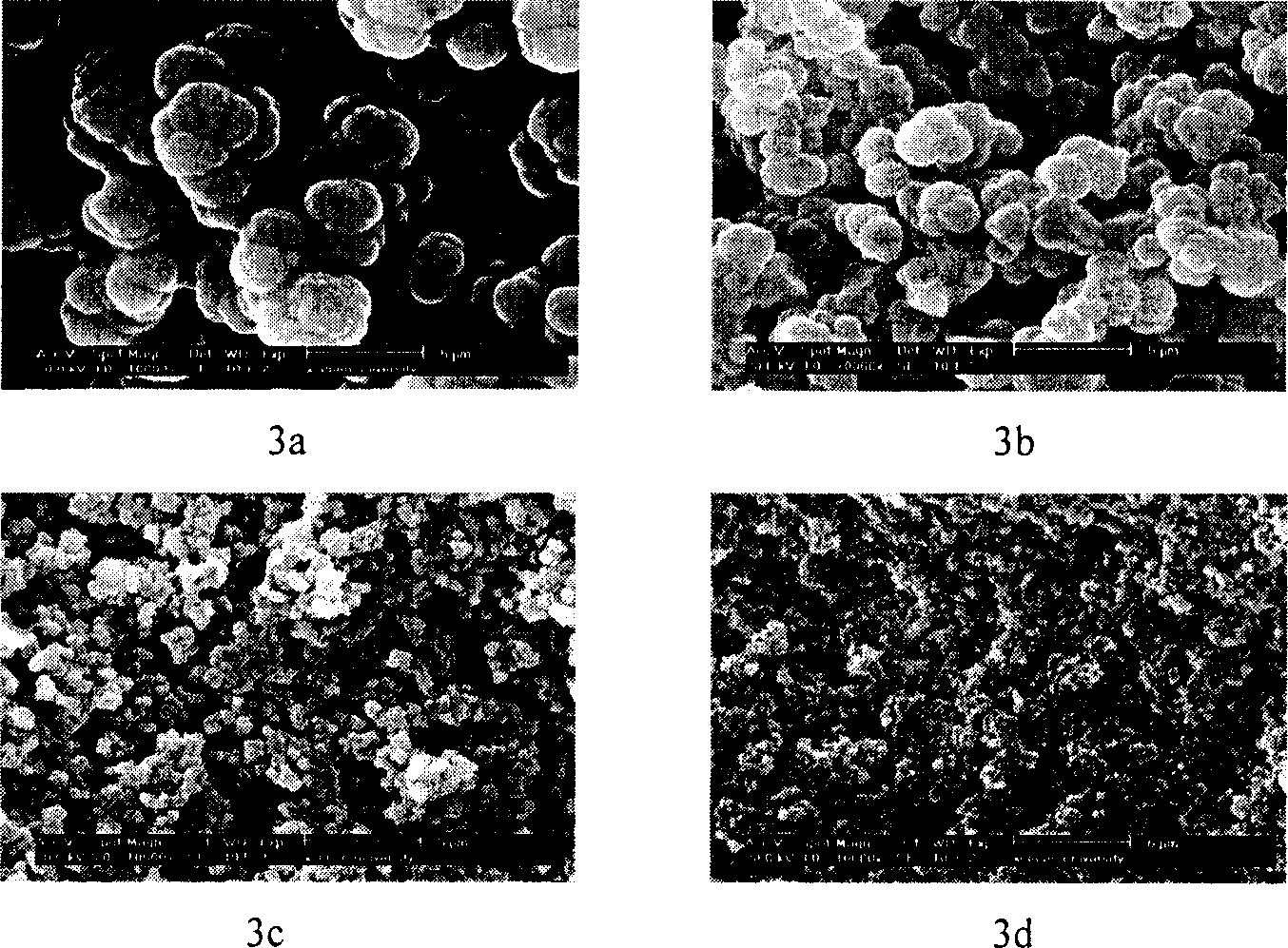

[0039] The cleaning and activation treatment of the inner wall of the capillary is the same as in Example 1. In the pre-bonding of the inner wall of the capillary, take 2.0 mL of γ-methacryloxypropyltrimethoxysilane (γ-MAPS) and add 2 μL of dry formic acid, and the others are the same as in Example 1. OMA: EDMA: AIBN=49.5: 49.5: 1 configuration reaction monomer mixture; The porogen is made up of 70% n-propanol and 30% 1,4 butanediol, and the proportion of the reaction monomer mixture and the porogen is respectively 45:55; 50:50; 55:45; 70:30 After mixing, nitrogen blowing, ultrasonic vibration and degassing for 15 minutes were injected into the pre-bonded capillary, one end was sealed and the other end was sealed after ultrasonic vibration. After reacting in a water bath at 50°C for 20 hours, connect it to the liquid chromatography pump and wash it with acetonitrile for 8 hours. image 3 3a, 3b, 3c, and 3d in the figure are the scanning electron micrographs of the proportions ...

Embodiment 3

[0041] The cleaning and activation treatment of the inner wall of the capillary is the same as in Example 1. In the pre-bonding of the inner wall of the capillary, take 2.0 mL of γ-methacryloxypropyltrimethoxysilane (γ-MAPS) and add 5 μL of dry acetic acid. Others are the same as in Example 1. Prepare OMA: EDMA is respectively 69.5: 29.5, 64.5: 34.5, 59.5: 39.5, 54.5: 44.5, and AIBN is a reaction monomer mixture of 1; porogen consists of 70% n-propanol and 30% 1,4-butanediol Composition, the reaction monomer mixture and the porogen are mixed in a ratio of 40:60, then blown with nitrogen and degassed by ultrasonic vibration for 15 minutes, inject it into a pre-bonded capillary, seal one end and seal the other end after ultrasonic vibration. After reacting in a water bath at 60°C for 20 hours, connect it to the liquid chromatography pump and wash it with acetonitrile for 5 hours. Figure 4 4a, 4b, 4c, and 4d in are the SEM images of OMA:EDMA=69.5:29.5; 64.5:34.5; 59.5:39.5; 54.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com