Instrument for detecting food allergen

A technology for detecting instruments and allergens, which is applied in the field of food allergen detection, can solve problems such as poor parallelism, long detection cycle, and low integration, and achieve the effect of improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Extraction of food allergens with biochemical methods

[0033] Take peanuts as an example: take 1 gram of peanut samples, put them in a -70°C refrigerator for 10 minutes, take them out, cut them into pieces with scissors, and add an appropriate amount of pre-cooled ether-acetone (1:2) to degrease. Acetone degreases continuously for 48 hours, during which time the liquid is changed 5 times (every 8-10 hours), and placed under a fume hood to let it dry naturally. All the above operations were carried out on ice bath.

[0034] After degreasing, the samples were weighed and soaked in bicarbonate-saline extract (Coca’s) at a certain ratio. Add the extract at the ratio of 1g sample: 20ml Coca's solution (w / v). At the same time, the samples were fully ground and crushed with a plunger homogenizer. The crushed samples were extracted with Coca's solution for 48hr. During this period, the samples were fully stirred and placed in a refrigerator at 4°C.

[0035] Cen...

Embodiment 2

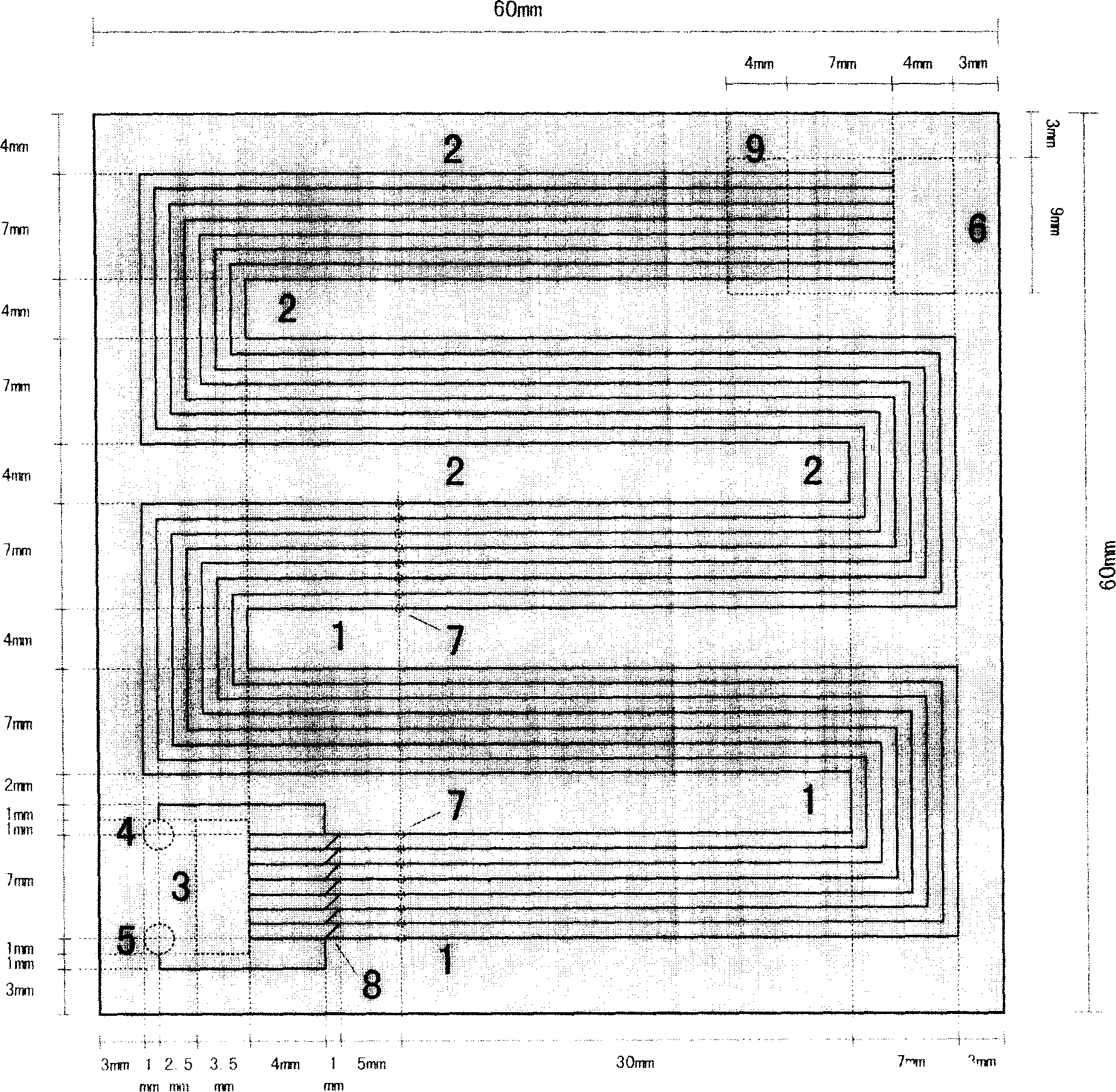

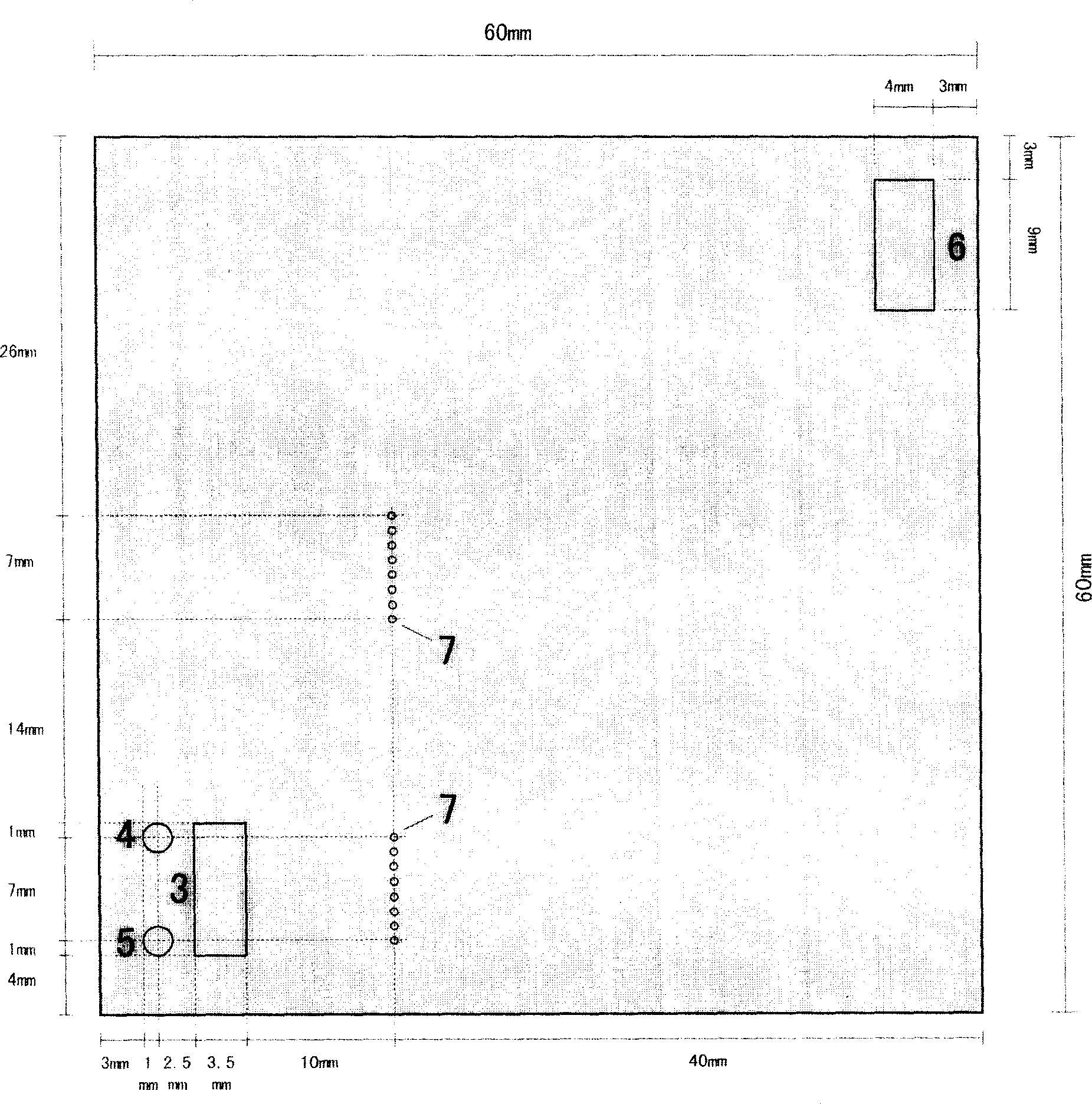

[0036] Embodiment 2: Preparation of capillary electrophoresis chip

[0037] According to attached figure 2 And attached image 3 The capillary electrophoresis chip design scheme, with glass as the chip substrate, is divided into two pieces of glass with the same size: negative film (attached figure 2 ) and cover slip (with image 3 ), the size is 60 mm x 60 mm; figure 2 Each channel is etched by laser or chemical method, the width of each channel is 20 microns, and the total number of channels is 8 with a depth of 60 microns; image 3 , open through holes at the positions marked 3, 4, 5, 6, and 7; after the bottom sheet and the cover sheet are respectively processed, the two are tightly combined with a high temperature method to make a capillary electrophoresis chip; then in the electrophoresis separation channel ( attached figure 1 In 1 and 2) a layer of polyacrylamide coating is fabricated on the tube wall, and monoclonal antibodies of different food allergens are bond...

Embodiment 3

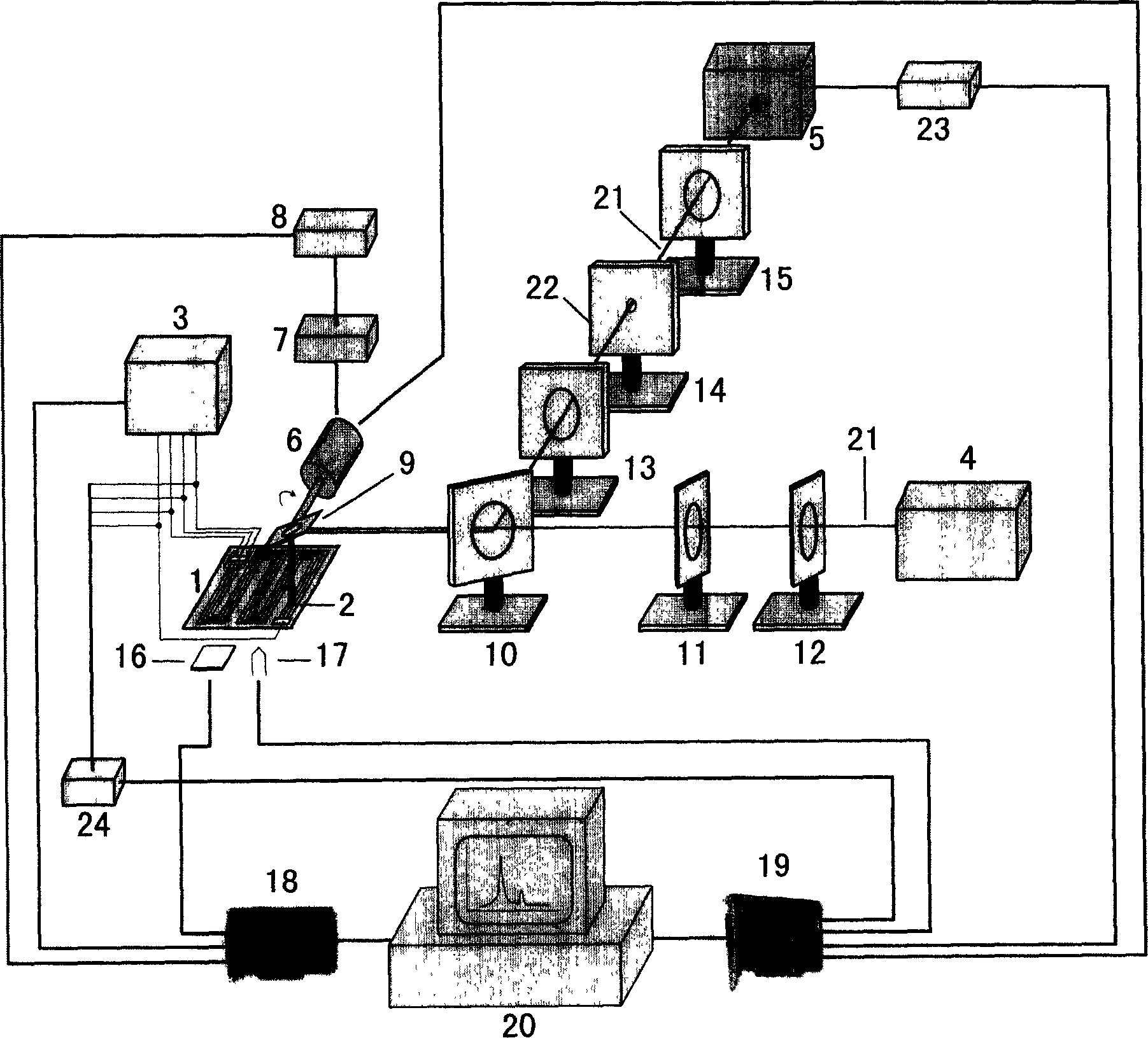

[0038] Embodiment 3: capillary electrophoresis system

[0039] According to attached figure 1 Set up the chip capillary electrophoresis system as described in . As described in Example 1, prepare a capillary electrophoresis chip for food allergen detection, use 4 platinum wires as electrodes, and use 4 negative high-voltage power supplies with linearly controllable voltage as the electrophoresis voltage drive, and its voltage and voltage controllable range 0 to -10kV, the output power is 10kV / 5mA; the ground terminals of the four high-voltage power supplies are connected together, and two of the high-voltage terminals are used for the voltage drive of the separation channel, and are respectively connected to the electrophoresis buffer pool through the electrodes (attached figure 2 , Mark 3 of 3) and electrophoresis waste liquid tank (attached figure 2 , Mark 6 of 3), the other two high-voltage terminals are connected to the sample cell through electrodes (attached figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com