Tissue engineering bone and its construction and application

A technology of tissue engineering bone and construction method, which is applied in bone diseases, drug combinations, medical preparations containing active ingredients, etc. It can solve the problems of imperfect products, no obvious effect of bone defect repair, and difficulty in inducing activity to be fully exerted, etc. problems, to achieve the effect of easy processing and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

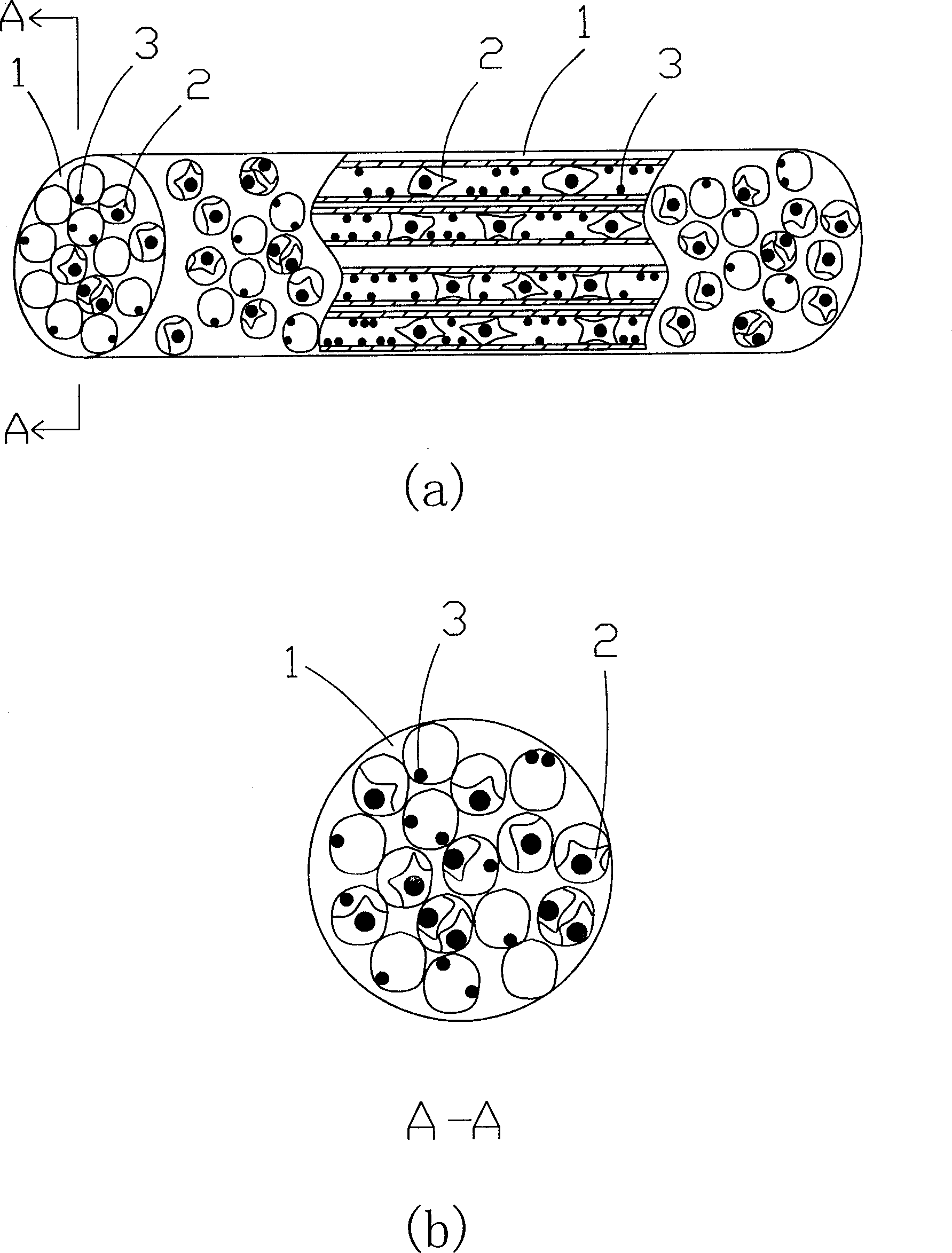

Image

Examples

Embodiment 1

[0041] Example 1: In vitro culture, expansion and directional induction of bone marrow stromal stem cells

[0042]According to the whole bone marrow cell culture method, the bone marrow puncture needle was inserted into the bone marrow cavity of the ilium, a total of 3-5ml of bilateral bone marrow was aspirated, mixed into DMEM medium, anticoagulated with 500U / ml heparin solution, mixed and then centrifuged at 800r / min at low speed for 5min , remove the supernatant, resuspend the culture medium and inoculate through a 90-mesh filter. At 37°C, 5% CO 2 Cultivate in an incubator, change the medium in half (DMEM complete medium, 15% serum) after 4 days, change the medium once in the next 2 to 3 days, observe daily with an inverted microscope, digest with 0.25% trypsin after the cells confluent into a monolayer, Counting, subculturing, and routinely changing the medium once every 3 days. The 3rd generation cells were transferred to DMEM conditioned medium (containing 15% serum, 5...

Embodiment 2

[0043] Example 2: Loading of PLGA scaffolds and cytokines

[0044] (1) Using modified PLGA with large pore size and high porosity as raw material, adding powdered cytokine bone morphogenetic protein, namely BMP, and trimming into shape;

[0045] (2) Ultrasonic vibration cleaning: use triple distilled water to clean with ultrasonic vibration, and dry naturally

[0046] (3) Surface deacidification treatment: immerse in 1% NaOH sequentially 2 2 hours, PBS buffer washing, 50% ethanol 2 hours, PBS buffer washing;

[0047] (4) Sterilize by ethylene oxide fumigation at 37°C;

[0048] (5) Add DMEM complete medium containing 15% serum and soak for 2-3 days;

[0049] (6) Add 10% polylysine solution and soak for 1-2 days;

[0050] (7) Dry under ultraviolet light at 15-25°C and store for future use.

[0051] In this embodiment, the PLGA scaffold is in the shape of a 4×4×2 mm block, with a pore diameter of 150-200 um and a pore diameter ratio of 85-95%.

Embodiment 3

[0052] Example 3: Construction of Tissue Engineered Bone Loaded with Cytokines

[0053] According to the method described in Example 1, the BMSCs that had passed the third generation and had grown well after being induced by the conditioned medium were digested with trypsin, centrifuged, and washed with 1×10 6 -1×10 7 / ml concentration Use a micropipette to inoculate the cell suspension onto the material constructed in Example 2, and place it at 37°C, 5% CO 2 Cultivate in the incubator for 4 hours, add an appropriate amount of conditioned medium, put it back into the incubator and continue to culture for 3-5 days, and then obtain the tissue-engineered bone and save it for future use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com