Method for decomposing potash feldspar ore by low temperature wet process

A potassium feldspar and wet process technology, applied in the field of decomposing potassium feldspar ore, can solve problems such as unsatisfactory comprehensive utilization of resources, high fluoride content, environmental or air pollution, etc., and achieves less discharge of three wastes and low preparation cost. , the effect of good market conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

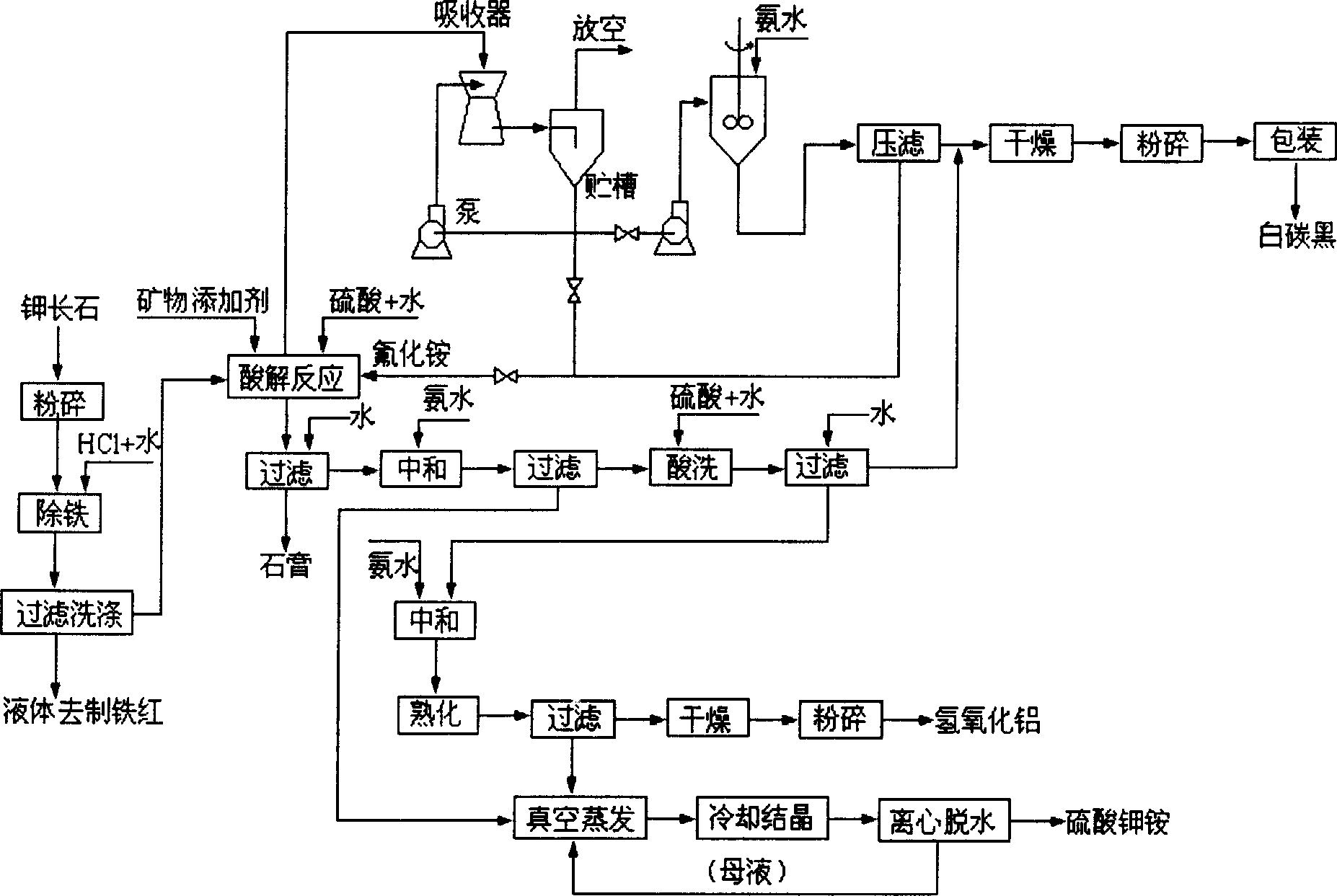

[0030] Such as figure 1 Shown, the method for low-temperature wet method decomposition potassium feldspar ore, it comprises the steps:

[0031] 1), take by weighing 100g potassium feldspar powder (-200 order), add water 100ml, add the hydrochloric acid 18-20ml that weight concentration is 30%, stir 1 hour at 60 ℃, filter, wash (except Cl - ) to obtain mother liquor A and filter cake A; mother liquor A is used to prepare iron oxide red, and mother liquor A is neutralized to pH=9.5-10 by adding 30% ammonia water with a weight concentration, and is oxidized by blowing air at normal temperature, and the oxidation reaction is 1.5- For 2.5 h, the product obtained from the oxidation was filtered and washed with deionized water until free of Cl - (Generally 3-4 times), to obtain liquid B and filter cake B, dry the filter cake B at 120-125°C for 2-3h, then calcinate at 650-670°C for 1h, cool to room temperature, and pulverize to obtain iron oxide Red (Fe 2 o 3 ) 3.426g.

[0032] 2...

Embodiment 2

[0038] Weigh 100g of potassium feldspar, mix it with 10g of fluorite after removing impurities with hydrochloric acid, add recovery solution containing ammonium fluoride (NH 4 F content is 20%) 250ml, add 160ml sulfuric acid reaction 1.5 hours again, other processes are the same as embodiment 1, make iron oxide red 3.506g respectively, white carbon black 64.82g, flame retardant aluminum hydroxide 19.08g and potassium ammonium sulfate 52g(K 2 O is 20.83%).

Embodiment 3

[0040] Weigh 100g potassium feldspar powder, after hydrochloric acid treatment to remove impurities, add 5g fluorite ore powder and 260ml (NH 4 F is 19.5%), add 165ml sulfuric acid after mixing evenly, other operation steps are unchanged, make iron oxide red 3.61g respectively, white carbon black 66.25g, aluminum hydroxide 19.42g, potassium ammonium sulfate 53.06g (K 2 O is 20.53%).

[0041] From the above three examples, it can be seen that whether the potassium feldspar ore powder is decomposed with fluorite plus sulfuric acid or decomposed with NH 4 F is decomposed with sulfuric acid, and the decomposition utilization rate of ore reaches 95%, which shows that the present invention has better industrialized utilization prospect.

[0042] Indicator name

GB 10517-89

The average content of this technology

SiO 2 content

DBP oil absorption value

/ (ml / 100g)

BET specific surface area

/ (m 2 / g)

Sieve residue (45μm)

/ %

H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com