Laminate hose made of fluorocopolymer

A technology of copolymers and hoses, applied in lamination, hoses, lamination devices, etc., can solve problems such as insufficient copolymerization, and achieve excellent interlayer adhesion, excellent durability, and excellent heat resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0083] The present invention will be described in further detail below in conjunction with examples. However, it should be understood that the present invention is not limited to these specific Examples. Unless otherwise stated, % means mass %.

[0084] The adhesive strength (interlaminar peel strength) of the film and the hose, the fuel permeability coefficient, and the NAH content were measured according to the following methods.

[0085] (i) The fuel permeability coefficient of the membrane (unit: g mm / m2 24 hours)

[0086] The fuel permeability coefficient of the fluorinated copolymer was measured according to the dish method described in JIS Z-0208. 9.5 to 10 grams of CE10 (volume ratio of isooctane:toluene:ethanol = 50 / 50 / 10) was added as fuel into a tray with a permeation area of 28.26 cm2. The cup was covered with a 100 micron thick film made of fluorocopolymer by thermocompression. From the mass loss of the disc after standing at 60°C for 10 days, the fuel perme...

preparation Embodiment 1

[0098] (1) Degas a polymerization vessel with an internal volume of 100 liters equipped with a stirrer, and then add 42.5 kg of 1,3-dichloro-1,1,2,2,3-pentafluoropropane (AK225cb, Asahi Glass Co., Ltd., hereinafter referred to as AK225cb), 2.125 kg CF 2 =CFO(CF 2 ) 3 F and 51 kg of HFP. Then, the temperature inside the polymerization vessel was raised to 50°C, and 4.25 kg of TFE was added to increase the pressure to 1.01 MPa / G. 340 cm3 of a 0.3% by mass peroxide (perfluorobutyryl) AK225cb solution was added as a polymerization initiator solution to initiate polymerization, and 340 cm3 of this polymerization initiator solution was added every 10 minutes.

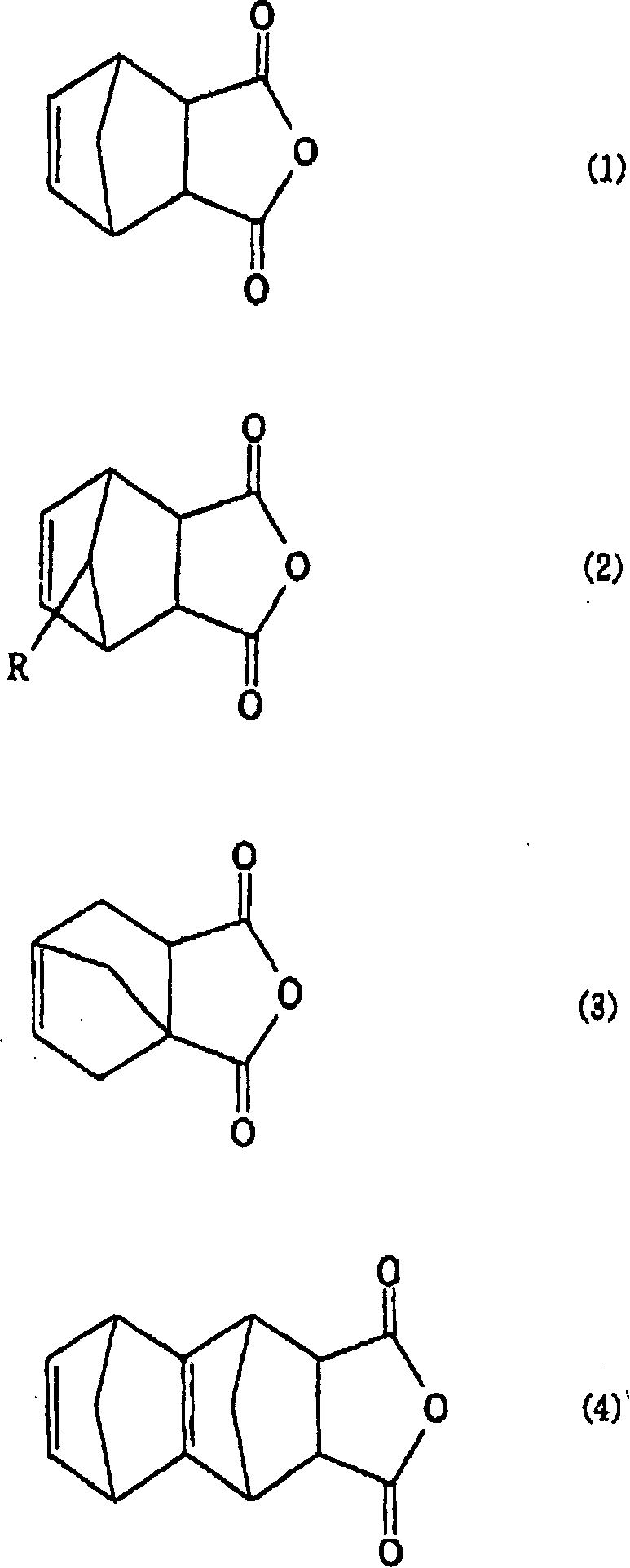

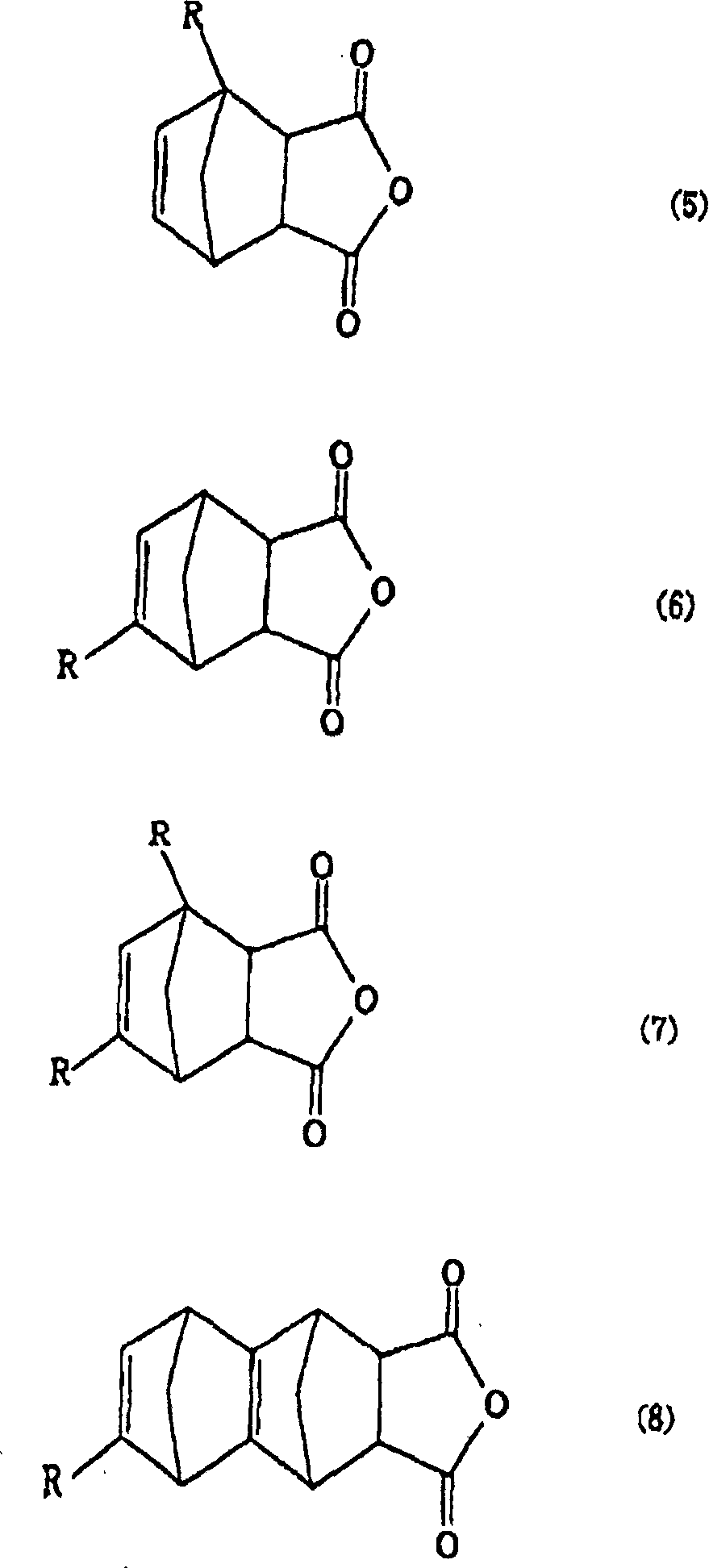

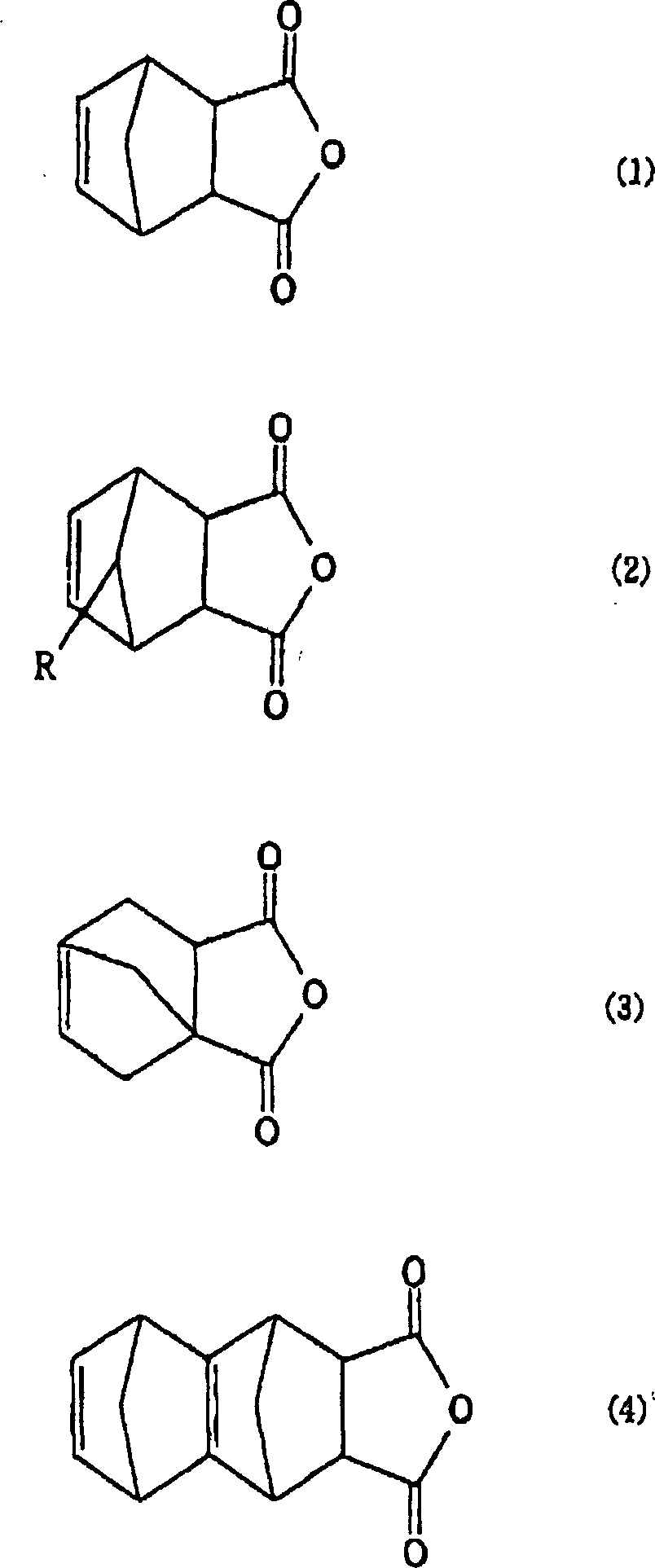

[0099] During the polymerization, TFE was continuously fed to maintain the pressure at 1.01 MPa / G. In addition, 0.3% by mass of NAH (using 5-norbornene-2,3-diacid anhydride represented by Formula 1) AK225cb solution was continuously added in an amount equal to 0.1 moles based on the moles of TFE added during the polymeriz...

preparation Embodiment 2

[0105] (1) Degas the polymerization vessel used in Preparation Example 1, then add 23.1 kg of AK225cb, 2.3 kg of methanol, 0.96 kg of CF 2 =CFO(CF 2 ) 3 F, 61.5 kg of HFP and 3.85 kg of TFE. Then the temperature inside the polymerization vessel was raised to 50°C and the pressure was 1.17 MPa / G. 340 cm3 of an AK225cb solution of 0.3% by mass of di(perfluorobutyryl) peroxide was added as a polymerization initiator solution to initiate polymerization, and 340 cm3 of this polymerization initiator solution was added every 10 minutes. Also, during the polymerization, TFE was continuously fed to maintain the pressure at 1.17 MPa / G. In addition, 0.3% by mass of NAH (using 5-norbornene-2,3-diacid anhydride represented by Formula 1) AK225cb solution was continuously added in an amount equal to 0.1% by mole of the number of moles of TFE to be continuously fed during polymerization. After 4 hours and 30 minutes of polymerization initiation, when 8.5 kg of TFE was added, the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com