Method for preparing carbon nano material by micro wave radiation of coal

A technology of carbon nanomaterials and microwave irradiation, which is applied in the field of nanomaterial technology and microwave chemistry, can solve the problems of expensive plasma generators, high production costs, and electrode burnout, and achieve short preparation cycles, less burnout, and The effect of less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

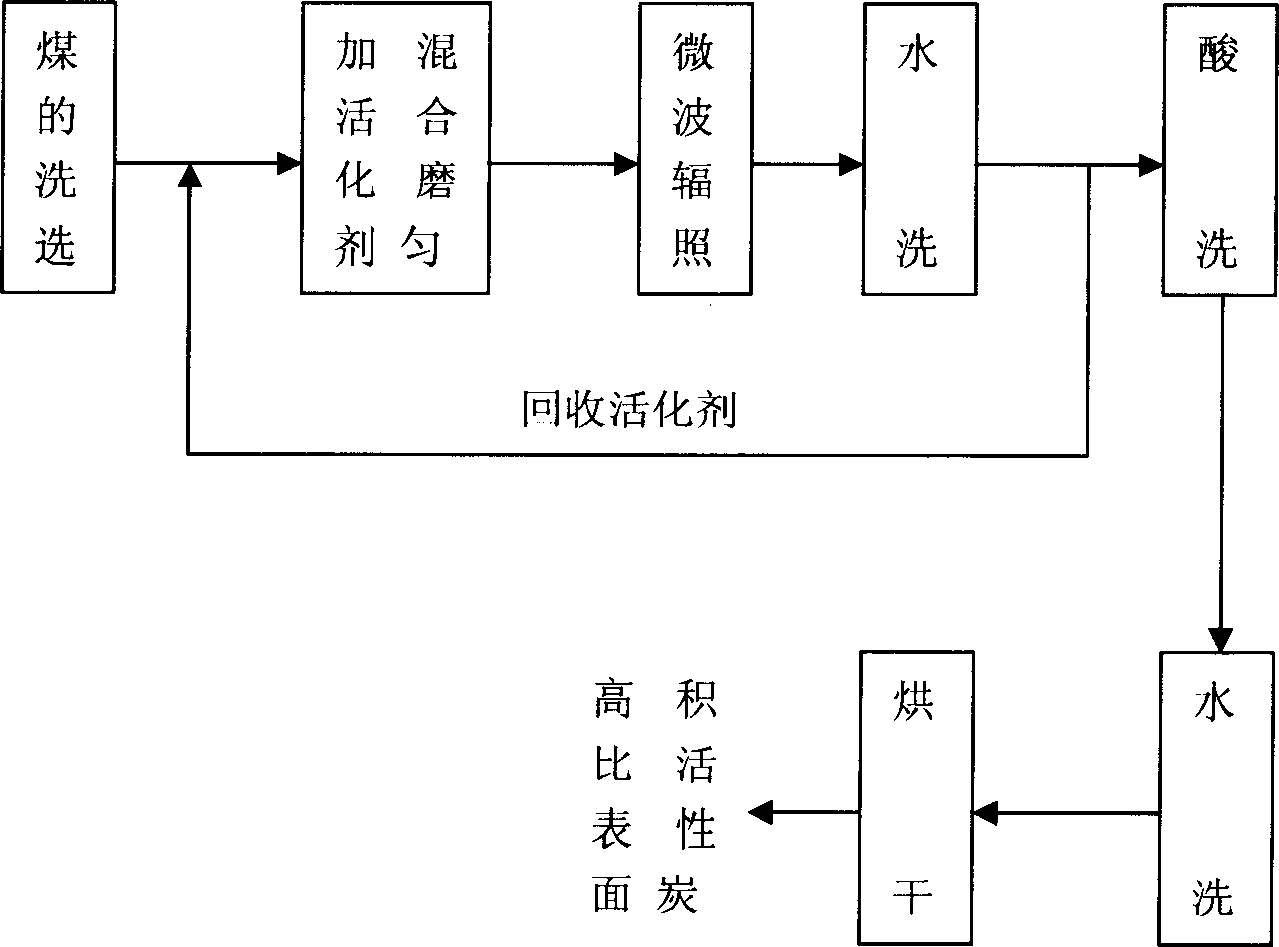

[0017] The washed bituminous coal and potassium hydroxide are mixed in a mass ratio of 1:4, and the mixture is evenly ground with a stirring mill, placed in a microwave oven with a power of 700W, irradiated in a nitrogen atmosphere for 20 minutes, and washed with water after being taken out. The washing liquid enters the recovery tank; the solids after washing are added with 10% hydrochloric acid solution for acid washing, and then washed and dried to obtain a specific surface area of 3000m 2 Activated carbon with high specific surface area above / g.

Embodiment 2

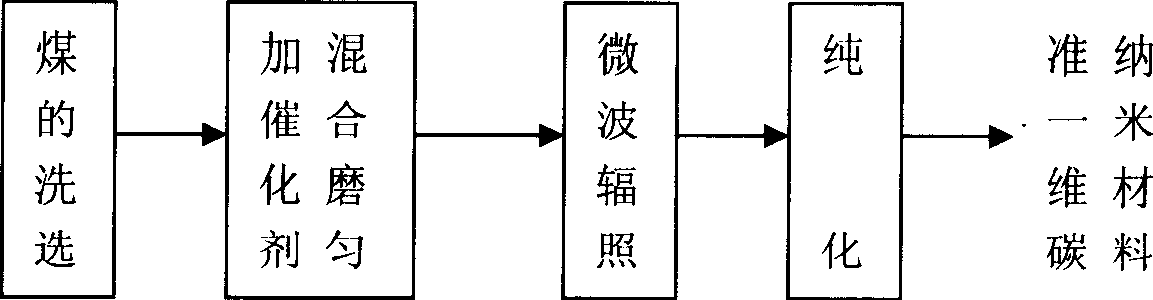

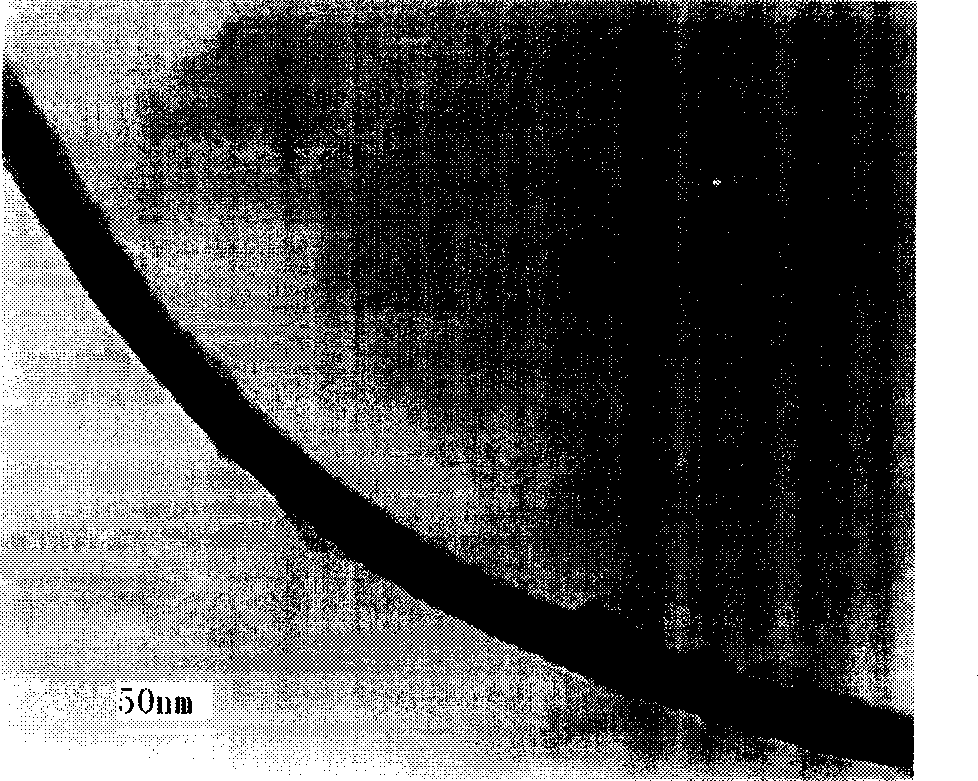

[0019] Add nanometer Fe powder with a mass ratio of 2% to the washed anthracite, mix it with a stirring mill, and put it in a microwave oven with a power of 1000W. It is heated, burned and arced in an air atmosphere. The irradiation time is 15 minutes, and after taking it out, it is pickled and purified with a 98% concentrated sulfuric acid solution to obtain a mixture of carbon nanotubes and carbon nanofibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com