Solid-liquid treating machine and its heating system

A technology of heating system and supply system, which is applied in the direction of fixed filter elements, filtration separation, chemical instruments and methods, etc., to achieve the effect of reducing specific resistance and accelerating filtration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

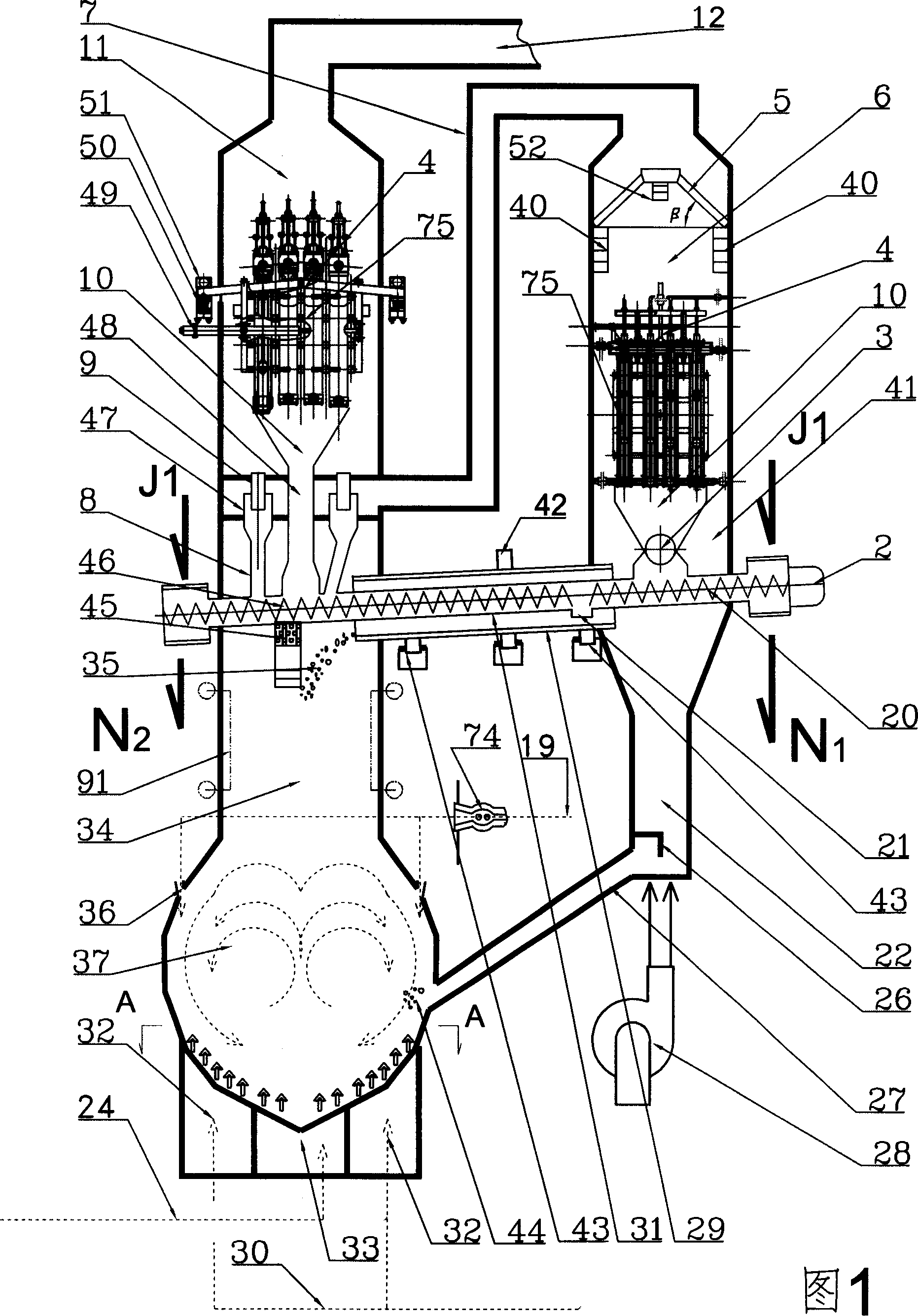

[0081] Within the scope of power of the present invention, it is combined into a device for producing cracked raw gas by utilizing organic raw materials. Put the sludge raw material biomass with a temperature of 15-25°C, a particle size of ≤3mm, and a water content of 80-96% into the filter chamber 4 of the hot-pressed flexible tubular solid-liquid disposal machine, and remove the filter residue after hot-pressing and dehydration. The temperature is 60-90°C, the water content is 65-70%, and it enters the drum drying device 29 through the cloth screw conveying device 31. At the same time, hot fluidized grains with a temperature of 130-180°C are added, and the temperature in the drum of the drum drying device 29 is 350°C. , after drying, the filter residue temperature is 95~210°C, and the water content is 15~30%. pressure) 0.02Mpa, the thermal reaction furnace adopts three areas of moving bed 32, fluidized bed 33 and slag discharge 62, the area of moving bed 32 adopts the back...

Embodiment 2

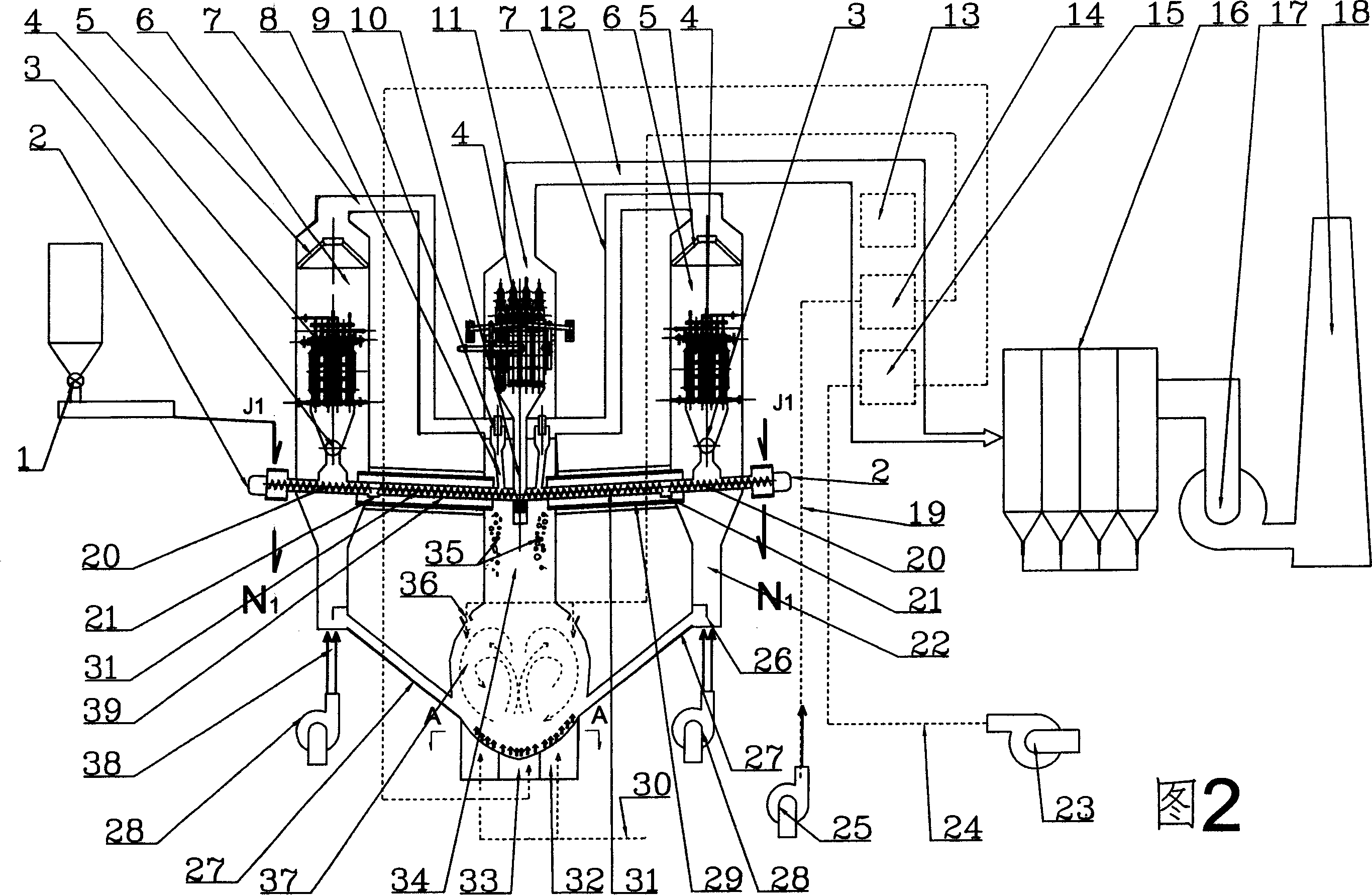

[0083]Within the power scope of the present invention, it is combined into a device that burns part of the organic raw materials to provide heat, and dries the rest of the raw materials to make solid-phase fuel. Put the sludge raw material biomass with a temperature of 15-25°C, a grain diameter ≤ 3mm, and a water content of 80-96% into the filter chamber of the hot-pressed flexible tubular solid-liquid disposal machine, and remove the filter residue after hot pressing and dehydration. At this time, the temperature of the filter residue is 60-90°C, water content 65-70%, enter the drum drying device 29 through the cloth screw conveying device 31, the temperature inside the drum of the drum drying device 29 is 150-210°C, and the temperature of the filter residue after drying is 95-120 ℃, water content 35-45%, the filter residue enters thermal reaction furnace 35, incineration temperature is 450-650 ℃, thermal reaction furnace adopts two sets of moving bed 59, two regions of fluidi...

Embodiment 3

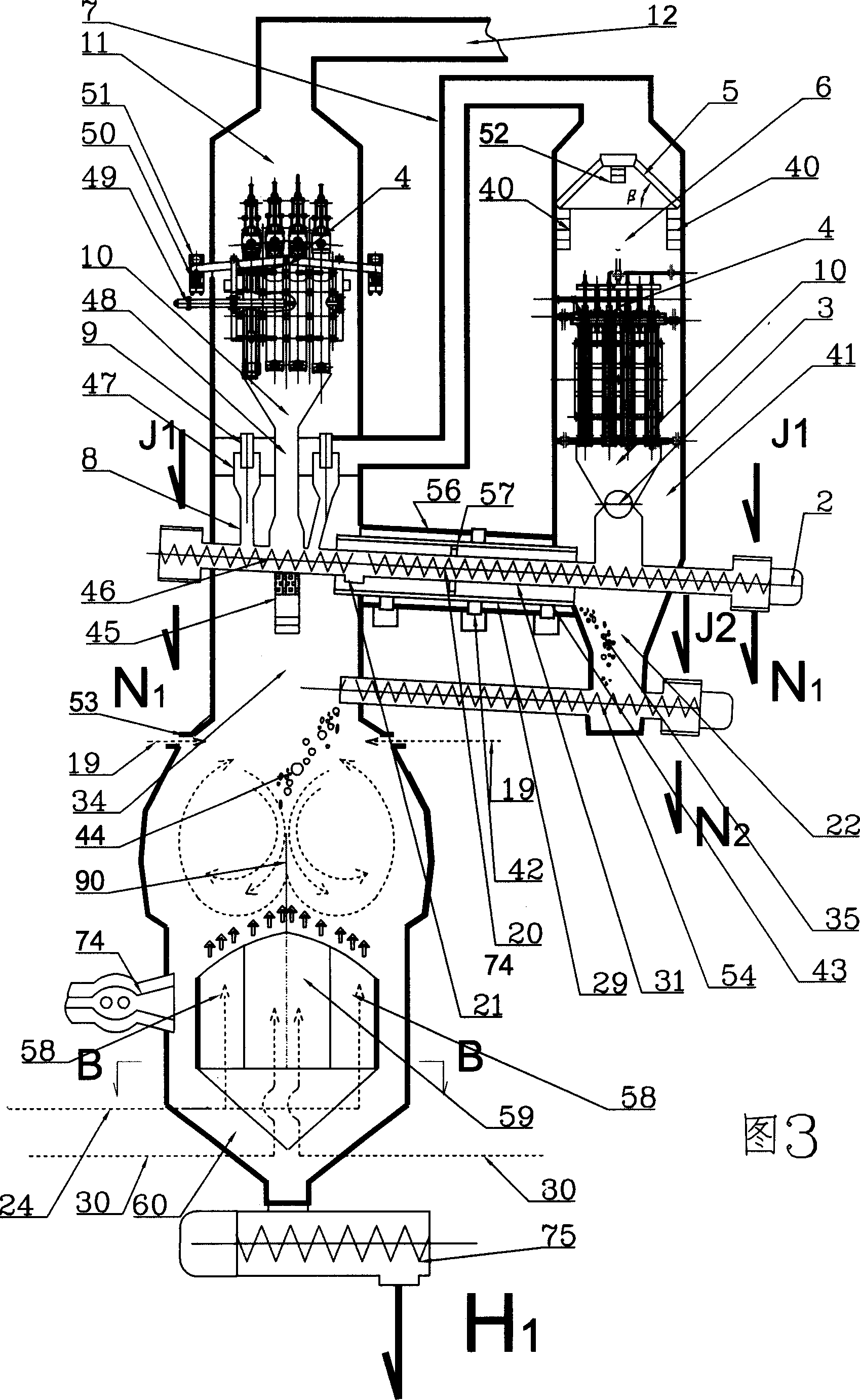

[0085] Combined into raw material drying equipment within the scope of power of the present invention. Put the inorganic raw materials with a temperature of 15-25°C, a diameter of ≤3mm, and a water content of 80-96% into the filter chamber of the hot-pressed flexible tubular solid-liquid handler, and remove the filter residue after hot-pressing and dehydration. At this time, the temperature of the filter residue is 80-96%. 90°C, water content 65-70%, enter the drum drying device 29 through the cloth screw conveying device 31, and add hot fluidized grains at a temperature of 130-180°C at the same time, the temperature inside the drum of the drum drying device 29 is 150°C, after drying The filter residue 35 has a temperature of 95-120° C. and a water content of 25-45%. The filter residue 35 enters a thermal reaction furnace with an incineration temperature of 450-650° C. Two areas, the moving bed 59 area and the fluidized bed 58 area adopt the air 24,19 that passes through the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com