Synthesis method of ball-shaped mixed with/nickelnous hydroxide and multielement metal oxide and battery

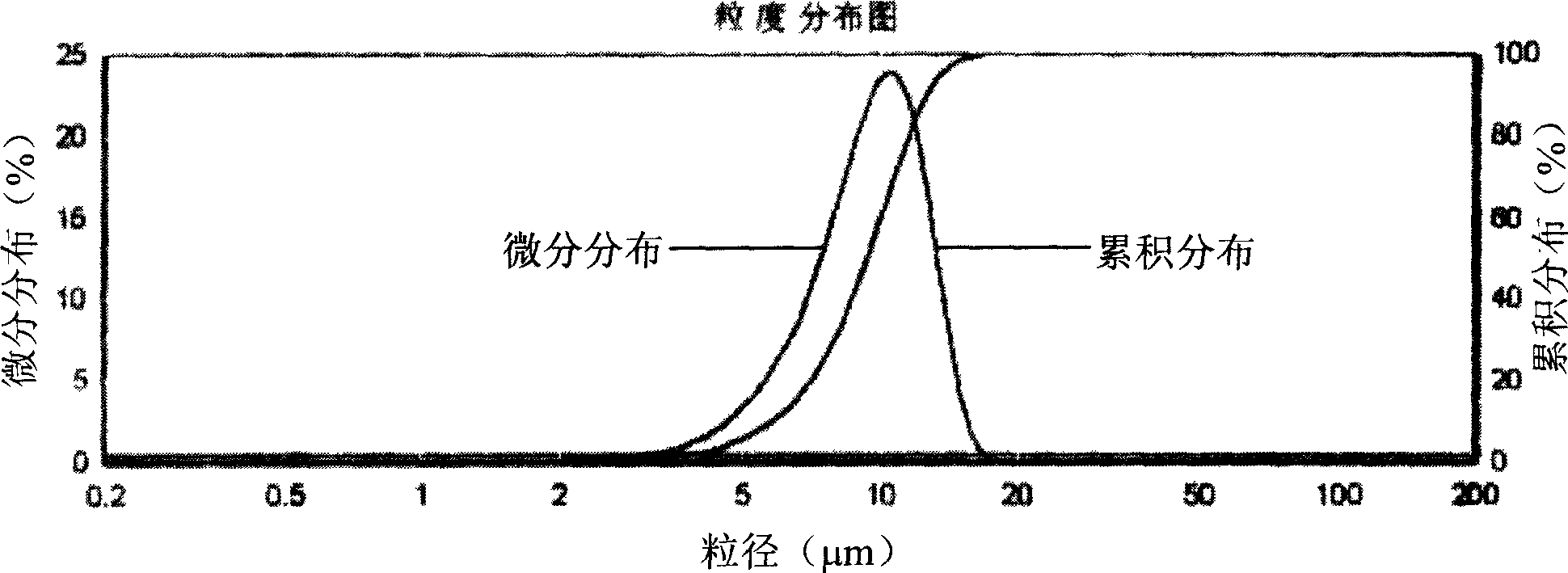

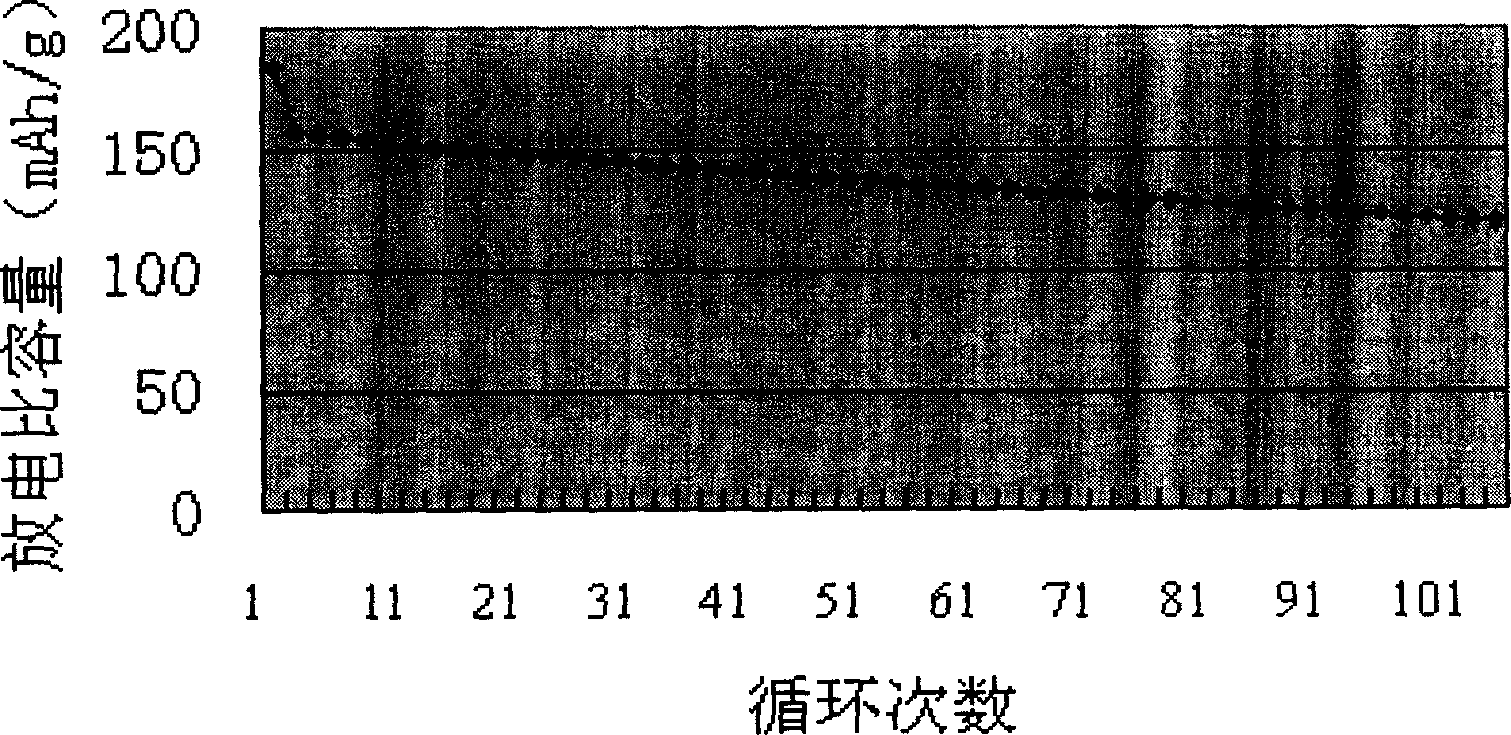

A nickel hydroxide and synthesis method technology, applied in the field of high-energy electrochemistry, can solve the problems of irregular microstructure of intermediate particles, destroy hierarchical structure, wide size distribution, etc., achieve uniform particle size, improve stability, and particle size distribution narrow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

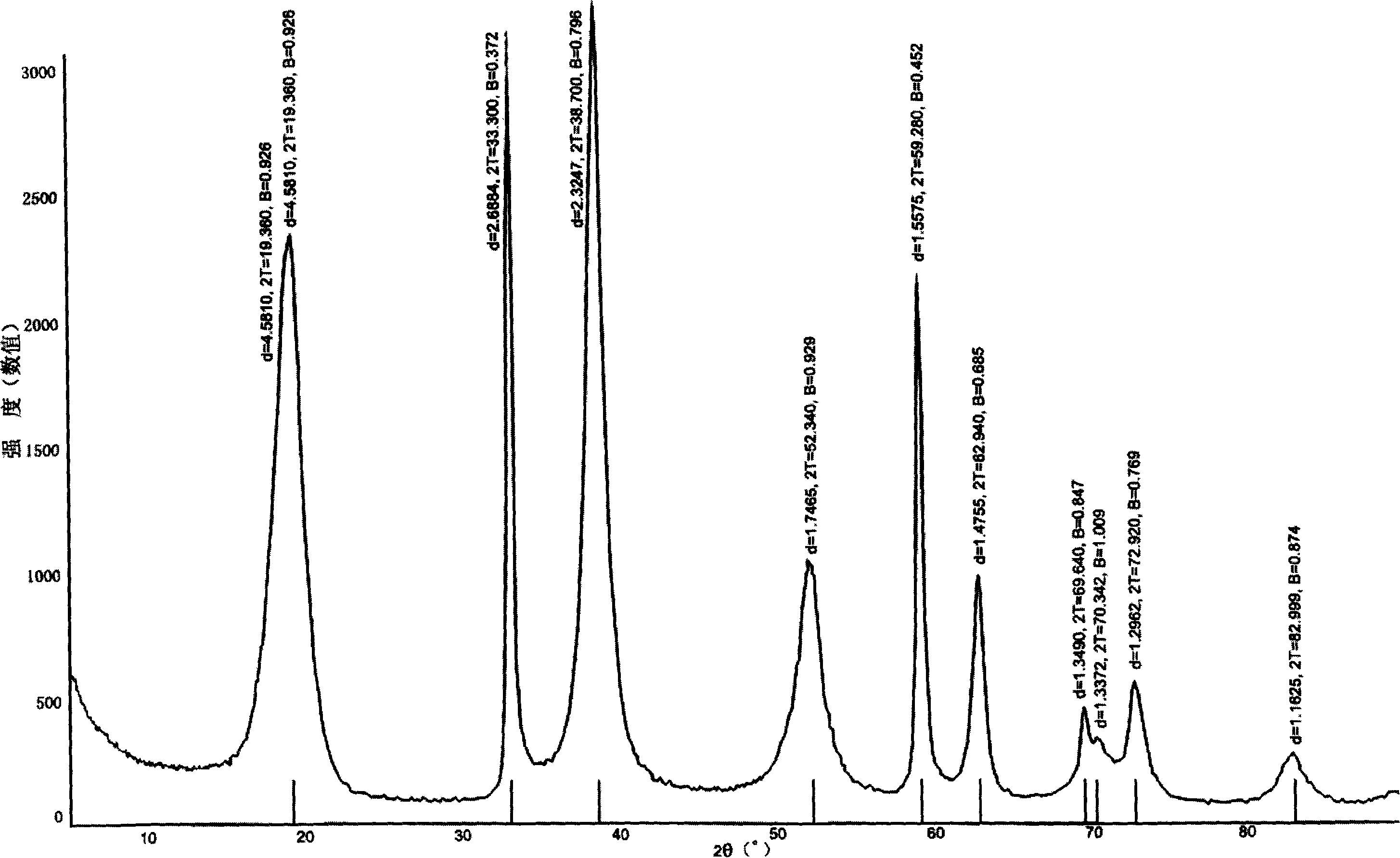

[0024] Example 1: Doping spherical nickel intermediate Ni 0.75 co 0.10 Al 0.15 (OH) n (method one)

[0025] The preparation method of the above-mentioned doped spherical nickel intermediate: the complex salt solution of nickel sulfate, cobalt sulfate, ammonia water, ammonium sulfate, and NaOH added with aluminum sulfate are added into a 40L reaction kettle in parallel, and Ni 2+ and Co 2+ The molar ratio is 0.75:0.10, the total salt concentration is 0.85mol / L, the ammonia concentration is 0.8mol / L, the ammonium sulfate concentration is 0.18mol / L, the NaOH concentration is 2.3mol / L, and the aluminum sulfate concentration is 0.15mol / L L, the bottom liquid is a mixed solution of ammonia and ammonium sulfate, the ammonia concentration is 0.4mol / L, and the ammonium salt concentration is 0.09mol / L. The reaction temperature is 50°C, the pH value is 11.5, the stirring speed is 600r / min, and the dark green spherical nickel intermediate Ni is obtained by co-precipitation. 0.75 co ...

Embodiment 2

[0030] Example 2: Doping spherical nickel intermediate Ni 0.75 co 0.10 al 0.15 (OH) n (Method Two)

[0031] The method of this embodiment is basically the same as in Example 1, except that the nickel salt, cobalt salt, ammonium salt and aluminum salt of the present embodiment are acetates, the alkali is KOH, and the stirring speed is 300r / min, and coprecipitation obtains deep Green spherical nickel intermediate Ni 0.75 co 0.10 al 0.15 (OH) n . Aging for 2 hours, washing with distilled water for 5 to 7 times to remove acetate ions, drying in an oven at 60°C for 12 hours and ball milling to obtain the precursor material.

Embodiment 3

[0032] Example 3: Doping spherical nickel intermediate Ni 0.75 co 0.10 al 0.15 (OH) n (Method 3)

[0033] The method of this embodiment is basically the same as in Example 1, except that the ammonia concentration of the present embodiment is 1mol / L, the ammonium sulfate concentration is 0.25mol / L, and the ammonia concentration in the bottom liquid is 0.5mol / L. Co-precipitated to obtain dark green spherical nickel intermediate Ni 0.75 co 0.10 al 0.15 (OH) n .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com