Heavy metal resistant catalytic cracking adjuvant and process for preparing same

A catalytic cracking additive and anti-heavy metal technology, applied in catalyst activation/preparation, catalytic cracking, metal/metal oxide/metal hydroxide catalyst, etc. Poor stability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

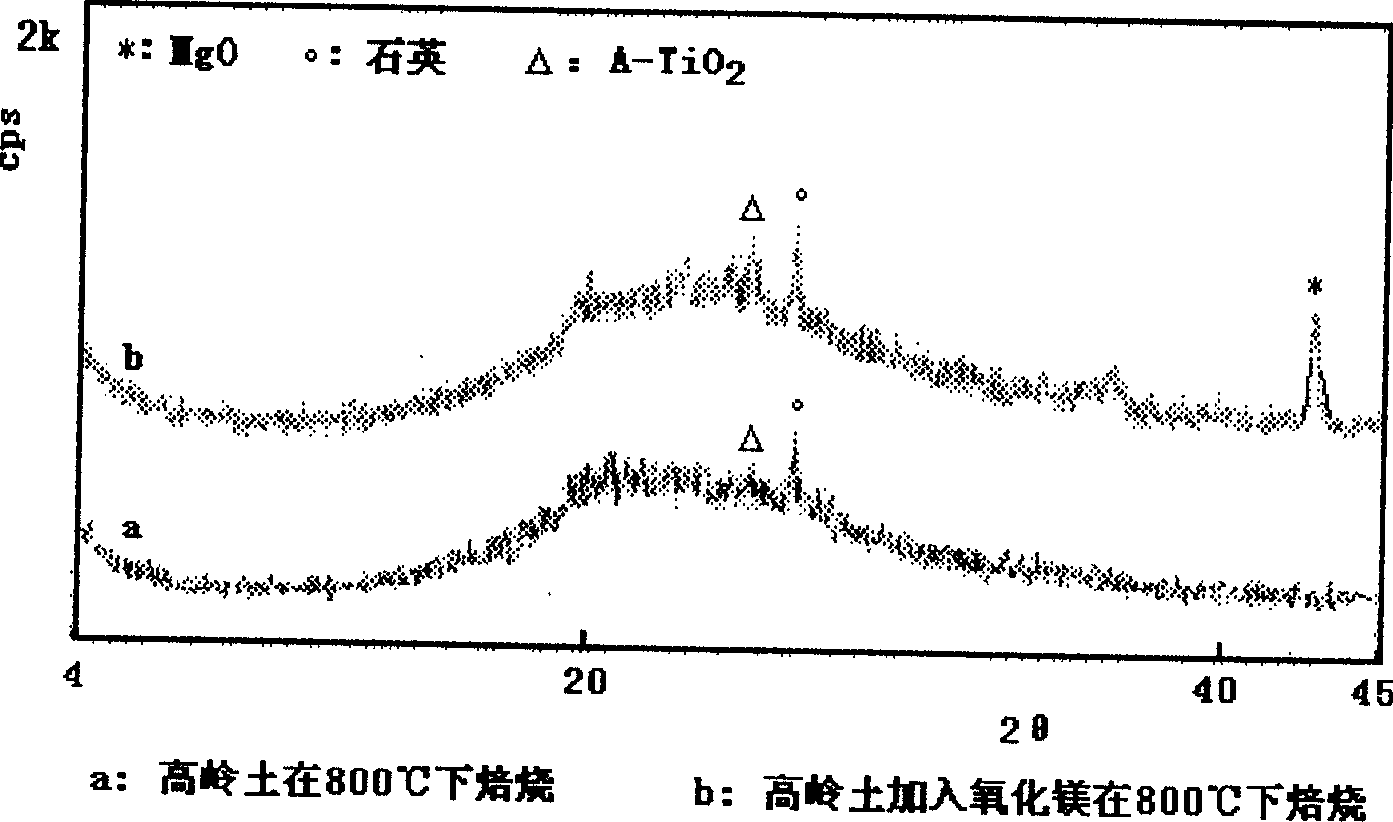

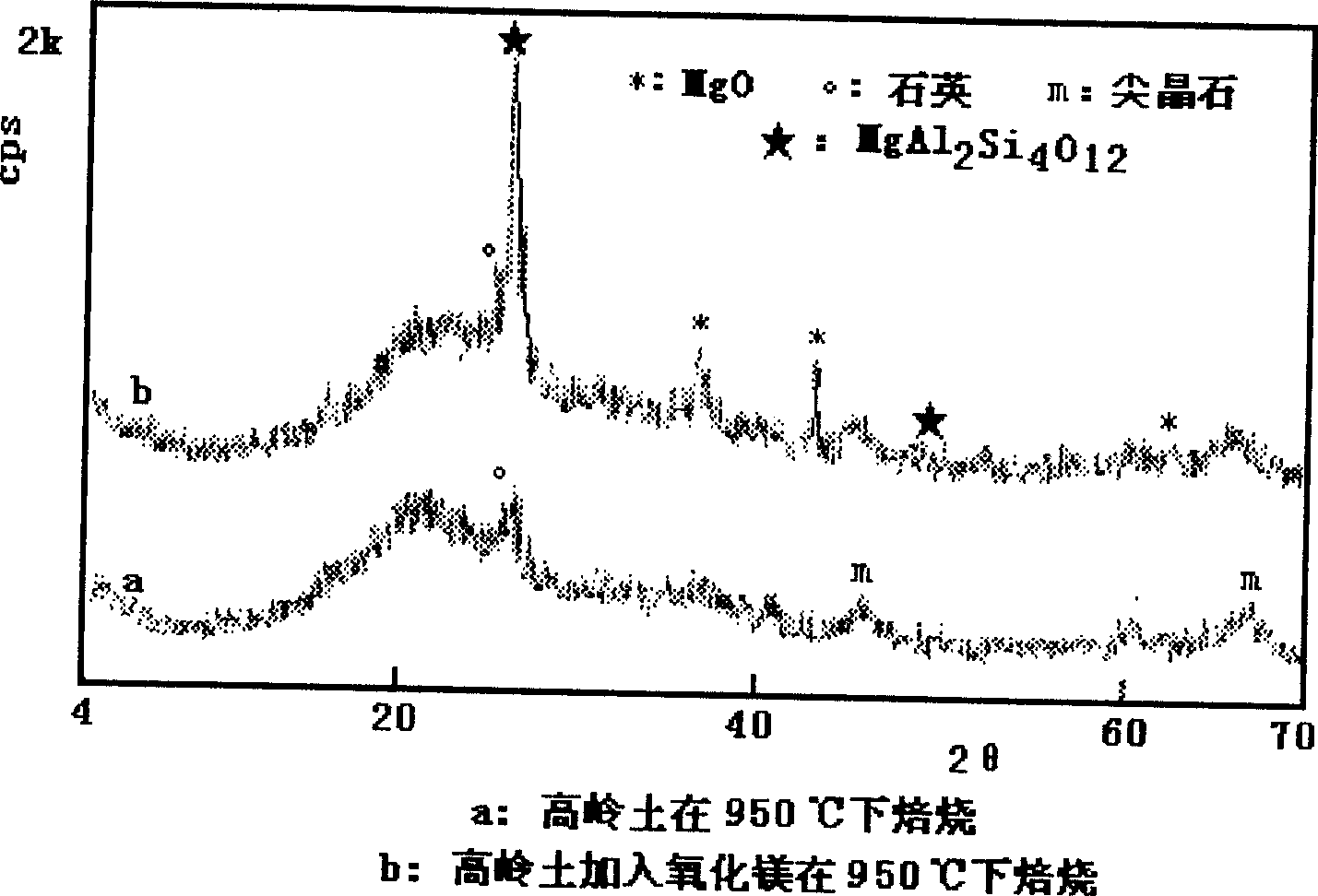

Method used

Image

Examples

Embodiment 1

[0061] Add water to 5 kg (dry basis) of Suzhou kaolin with a median diameter of 2.6 μm to make a slurry with a solid content of 38%, add 1400 ml of sodium silicate as an additive, and add 250 g of light magnesia to form kaolin microspheres by spraying. Obtain 3.9 kg of kaolin spray microspheres, which are roasted in a muffle furnace at 980° C. for 3 hours to obtain roasted kaolin microspheres, which contain 10% mullite and have a wear index of 1.0%. Put 500g of calcined microspheres into a stainless steel reactor and mix with NaOH lye in a stirring state, raise the temperature to 90°C and keep the temperature constant for 2 hours, after the extraction, remove the mother liquor by filtration, wash until NaOH 2 O 0.63%, add 37.7g RECl in the washing material 3 The mixed rare earth chloride solution, adjust the pH value with ammonia water, pH = 6.9, temperature 60 ° C, time 30 min, the product is filtered and dried as auxiliary agent A.

Embodiment 2

[0063] Add water to 2kg (dry basis) of Hancheng kaolin with a median diameter of 2.2 μm to make a slurry with a solid content of 42%, add 240g of sodium pyrophosphate as an additive, and add 332g of magnesium chloride, and spray-form it into kaolin microspheres to obtain 1.7 kg of kaolin sprayed microspheres, the sprayed microspheres were roasted in a muffle furnace at 1050° C. for 2 hours to obtain roasted kaolin microspheres, which contained 12% mullite and had a wear index of 0.5%. Put 1500g of calcined microspheres into a stainless steel reactor and mix with NaOH lye in a stirring state, raise the temperature to 70°C and keep the temperature constant for 5 hours, after the extraction, remove the mother liquor by filtration, wash until Na 2 O 0.52%, add 67.9g RECl in the washing material 3 The mixed rare earth chloride solution, adjust the pH value with ammonia water, pH = 8.1, temperature 90 ° C, time 10 min, the product is filtered and dried as auxiliary agent B.

Embodiment 3

[0065] Add water to 4kg (dry basis) of Suzhou kaolin with a median diameter of 2.6 μm to make a slurry with a solid content of 35%, add 160ml of sodium silicate and 70g of sodium carbonate as additives, and add 116g of magnesium hydroxide, and spray into kaolin micro Balls, a total of 2.8kg of kaolin spray microspheres were obtained, and the spray microspheres were roasted in a muffle furnace at 990° C. for 3 hours to obtain roasted kaolin microspheres, which contained 8% mullite and had a wear index of 0.7%. Put 200g of calcined microspheres into a stainless steel reactor and mix with NaOH lye under stirring state, raise the temperature to 80°C and keep the temperature constant for 3 hours. 2 O 0.50%, add 24.2g RECl in the washing material 3 The mixed rare earth chloride solution, adjust the pH value with ammonia water, pH = 8.6, temperature 25 ° C, time 60 min, the product is filtered and dried as auxiliary agent C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com