SiO2 core-polymer shell hybrid nanometer material preparation method

A technology of nanomaterials and synthesis methods, applied in the field of synthesis of nanomaterials, can solve the problems of uncontrollable structure, strong cohesion, and easy agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

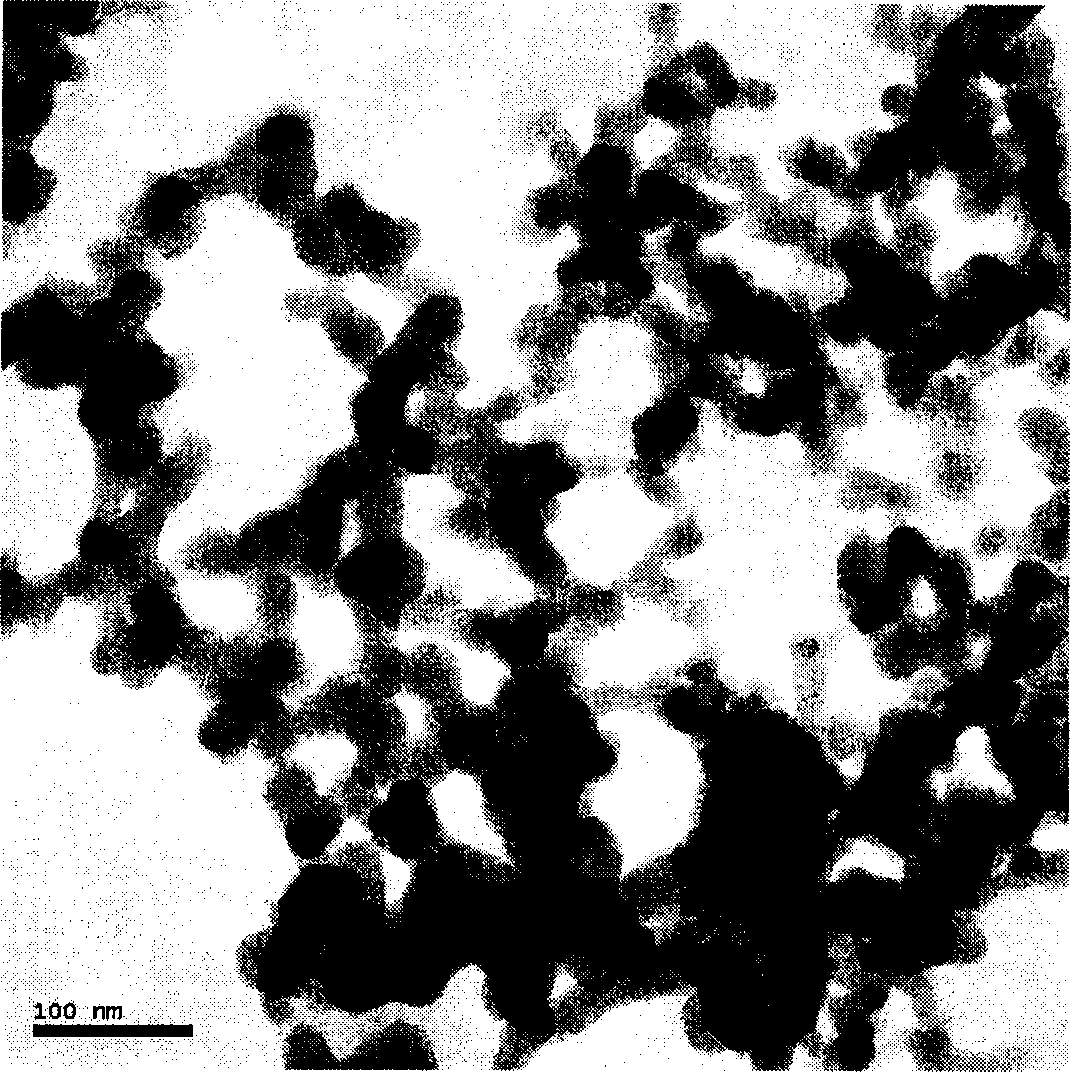

[0019] 1. Alkylated nano silica

[0020] In a round-bottomed flask filled with 200mL of toluene, add 4g of vacuum-dried nano-silica and 2g of γ-methacryloxypropyltrimethoxysilane (KH-570), ultrasonically disperse for 10min, and pass through the system Nitrogen, reflux at the reflux temperature of toluene, stir the reaction for 4h, cool down, let stand, precipitate, wash with ethanol fully, and vacuum dry for 24h.

[0021] 2. Surface graft polymerization of alkylated nano-silica

[0022] Add 90mL of deionized water, 3g of alkylated nano-silica, 0.133g of sodium dodecylbenzenesulfonate and 0.066g of OP-10 in a 250ml four-neck flask equipped with a stirrer, a condenser, and a nitrogen inlet. , 0.33g of isopropanol, 9g of methyl methacrylate, fully magnetically stirred, heated to 75°C; accurately weighed 0.1g of potassium persulfate dissolved in 10ml of deionized water, added dropwise to the above system within 0.5h, and then Continue to react for 3h, cool, filter, and spray dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com