Quick preparing method for textured single phase hexagonal ferrite

A technology of hexagonal crystal system and ferrite, which is applied in the field of information functional materials, can solve the problems of unsatisfactory calcination temperature and holding time, and achieve the effects of shortening the preparation cycle, saving electric energy, and being easy to produce at a large scale and at a low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

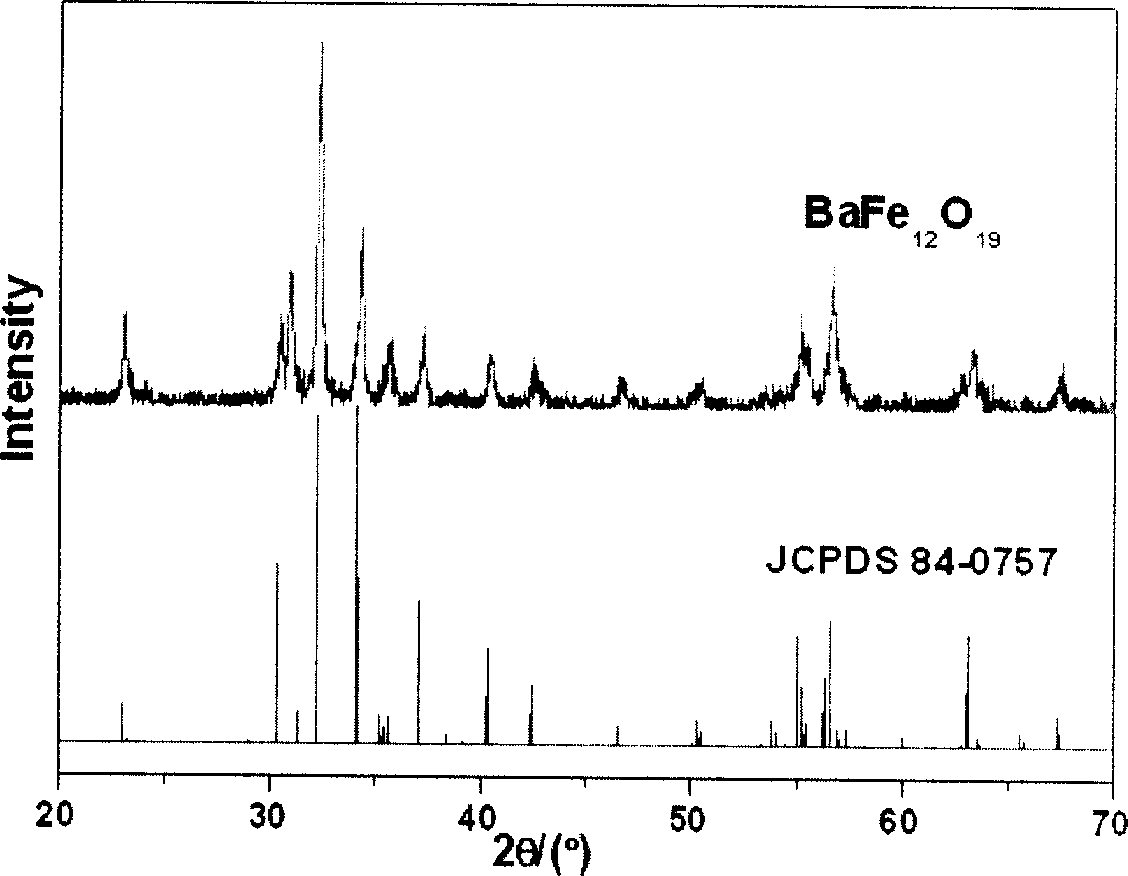

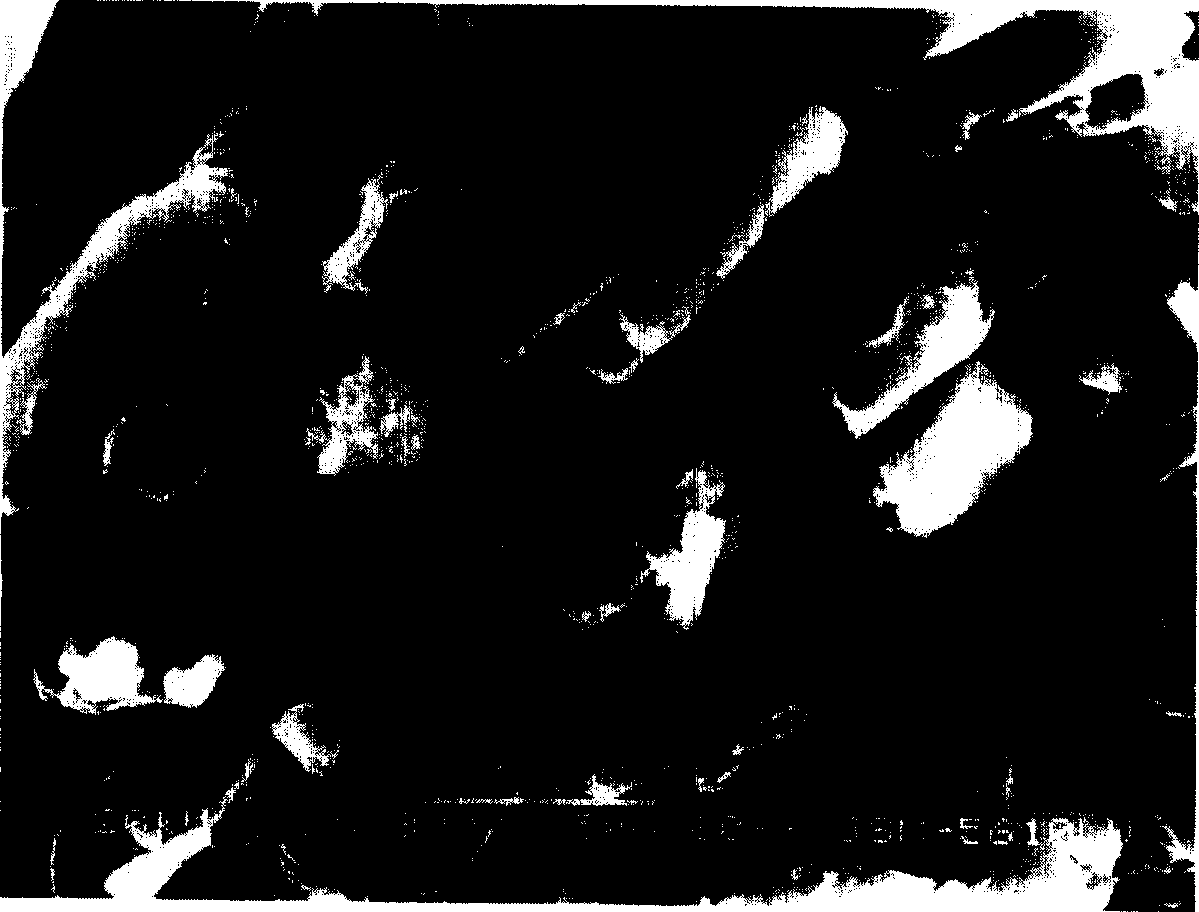

Image

Examples

Embodiment 1

[0016] (1) Weigh 4.0g of M-type barium ferrite co-precipitation precursor powder, put it into a high-strength graphite mold with an inner diameter of 15mm, an outer diameter of 45mm, and a lining of carbon paper, and place it in an SPS vacuum chamber;

[0017] (2) Temperature measurement by thermocouple;

[0018] (3) Start the vacuum system, and slowly load when the vacuum degree is lower than 10Pa, and the co-precipitation precursor realizes vacuum dense molding;

[0019] (4) Set the process parameters of SPS sintering: heating rate 200°C / min, sintering temperature 850°C, holding time 10min;

[0020] (5) When the pressure reaches the set value and stabilizes, start the SPS sintering program;

[0021] (6) After the program runs, the SPS sintering system is closed to obtain a textured single-phase hexagonal ferrite, and the density measured by the Archimedes drainage method is 91.5%.

Embodiment 2

[0023] Steps (1), (2) and (3) are the same as in Example 1. Other steps are as follows:

[0024] (4) Set the process parameters of SPS sintering: heating rate 200°C / min, sintering temperature 850°C, holding time 15min;

[0025] (5) When the pressure reaches the set value and stabilizes, start the SPS sintering system;

[0026] (6) After the program runs, the SPS sintering system is closed to obtain a textured single-phase hexagonal ferrite, and the density measured by the Archimedes drainage method is 93.4%.

Embodiment 3

[0028] Steps (1), (2) and (3) are the same as in Example 1. Other steps are as follows:

[0029] (4) Set the process parameters of SPS sintering: heating rate 200°C / min, sintering temperature 850°C, holding time 25min;

[0030] (5) When the pressure reaches the set value and stabilizes, start the SPS sintering system;

[0031] (6) After the program runs, the SPS sintering system is closed to obtain a textured single-phase hexagonal ferrite, and the density measured by the Archimedes drainage method is 95.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com