In site detecting method for building wall heat transfer coefficient

A heat transfer coefficient and building wall technology, which is applied in the field of on-site detection of building wall heat transfer coefficient, can solve problems such as difficulty in finding a suitable test site, equipment adaptability to a large site, and a large heat box to achieve shortening Test time, facilitate on-site installation and use, and enhance the effect of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

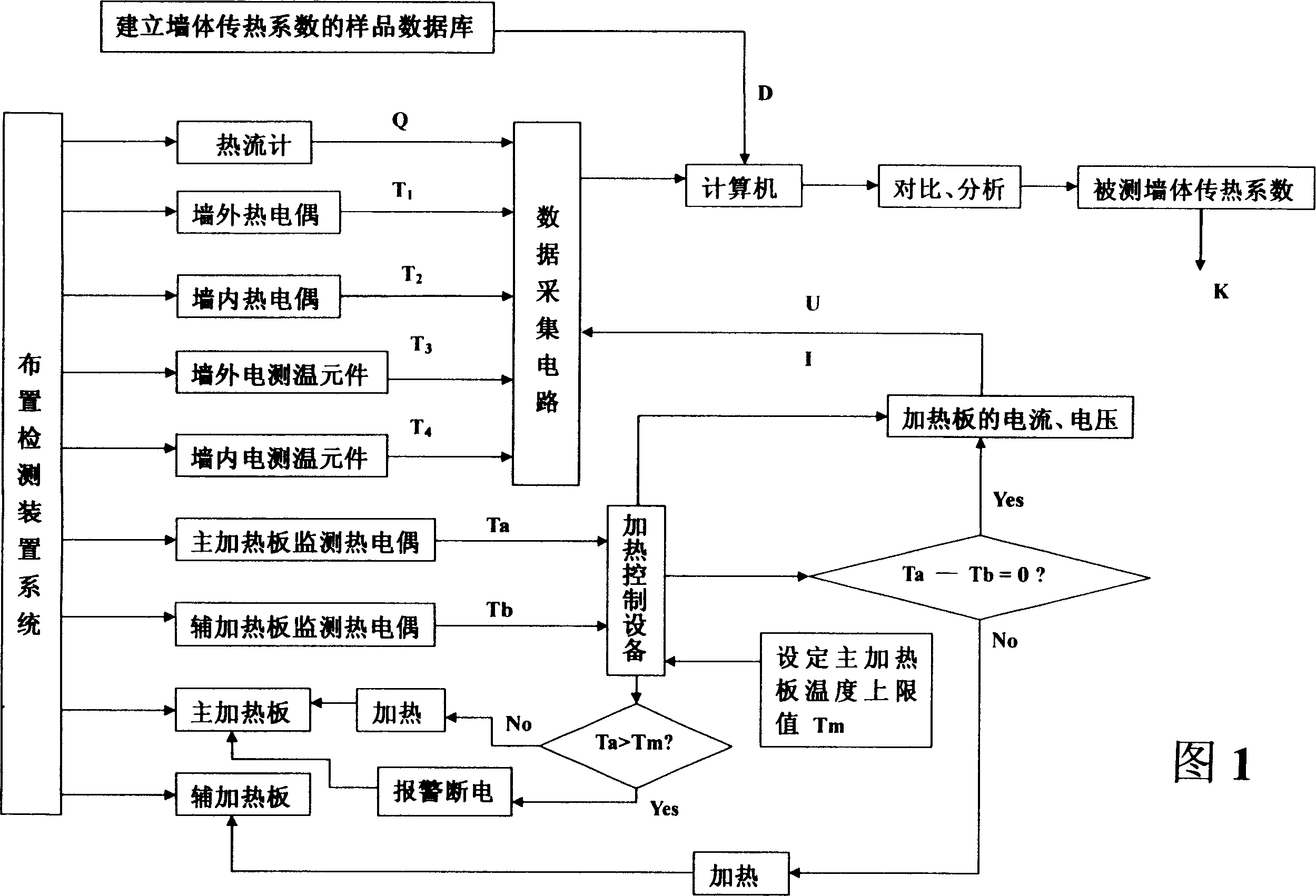

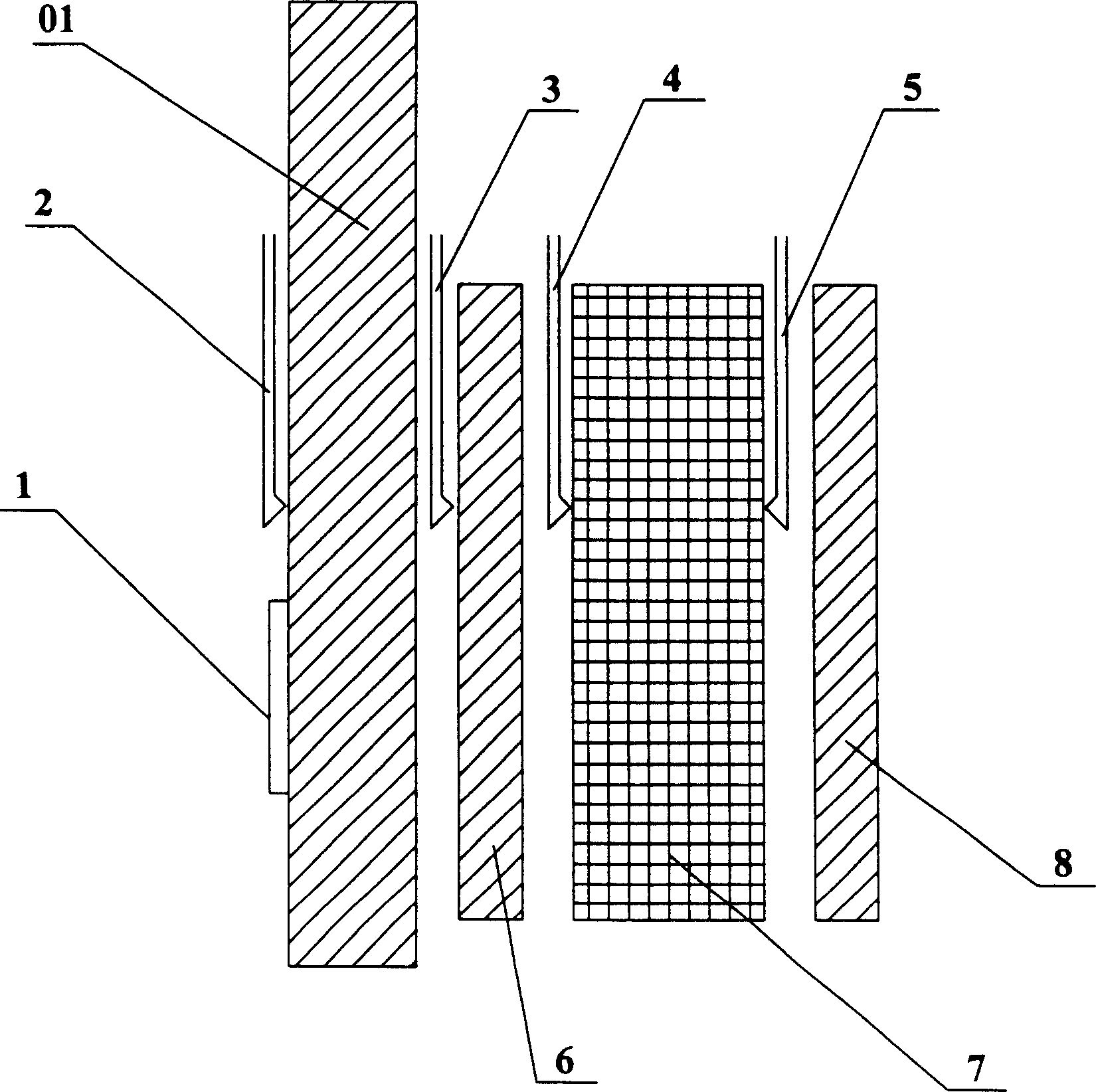

Embodiment 1

[0027] 1. Layout system: The tested wall 01 is composed of 20mm thick mixed mortar plaster, 240mm thick hollow clay brick wall, 20mm thick cement mortar, 50mm thick polystyrene board insulation layer and 10mm thick mixed mortar plastered surface. The measurement area is determined to be 400mm×400mm, the length and width of the main heating plate 6 and the auxiliary heating plate 8 are both 400mm, the thickness is 30mm, the output power is 32W, the thickness of the heat insulation plate 7 is 100mm, and the material is epoxy resin. The thermocouple 2 outside the wall is arranged with There are 9 thermocouples in the wall 3, and there are 7 thermocouples in the wall. The electric temperature measuring elements inside and outside the wall use thermal resistance, the inner layer of the heating device shell is made of thermal insulation cotton material, and all thermocouples are copper-constantan thermocouples. There is sample database D.

[0028] 2. Heating: set the upper temperatu...

Embodiment 2

[0033] 1. Layout system: The tested wall 01 is composed of 20mm thick mixed mortar plaster, 240mm thick hollow clay brick wall, 20mm thick cement mortar, 15mm thick polyurethane board insulation layer and 10mm thick mixed mortar plastered surface. The area is determined to be 400mm×400mm, the length and width of the main heating plate 6 and the auxiliary heating plate 8 are 400mm, the thickness is 30mm, the output power is 45W, the thickness of the heat insulation plate 7 is 100mm, and the material is epoxy resin. There are 7 thermocouples 3 arranged in the wall, thermometers are used for temperature elements inside and outside the wall, plastic foam material is used for the inner shell of the heating device, copper-constantan thermocouples are used for all thermocouples, and samples are stored in the computer. databaseD.

[0034] 2. Heating: Set the temperature upper limit Tm of the main heating plate 6 to 90° C., set the voltage U of the main heating plate 6 to 47.4 V, thus ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat transfer coefficient | aaaaa | aaaaa |

| Heat transfer coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com