Preparation method of polysulfone-polyethylene epoxide block copolymer

A technology of polyethylene oxide and block copolymers, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of low molecular weight of block copolymers, wide molecular weight distribution, complicated operation steps, etc. Achieve the effects of excellent mechanical properties, narrow molecular weight distribution, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Preparation of polyethylene oxide whose end group is a halogen atom

[0027] Add 15.0g (10.0mmol) of polyethylene oxide with a molecular weight of 1500 and 3.0mL (40.0mmol) of thionyl chloride to the dry reaction flask, and heat the reaction system to 120°C under the protection of an inert gas. And react at this temperature for 10 hours, then distill and remove the residual thionyl chloride in the reaction bottle to obtain 15.0 g of polyethylene oxide whose end group is chlorine, yield: 100%.

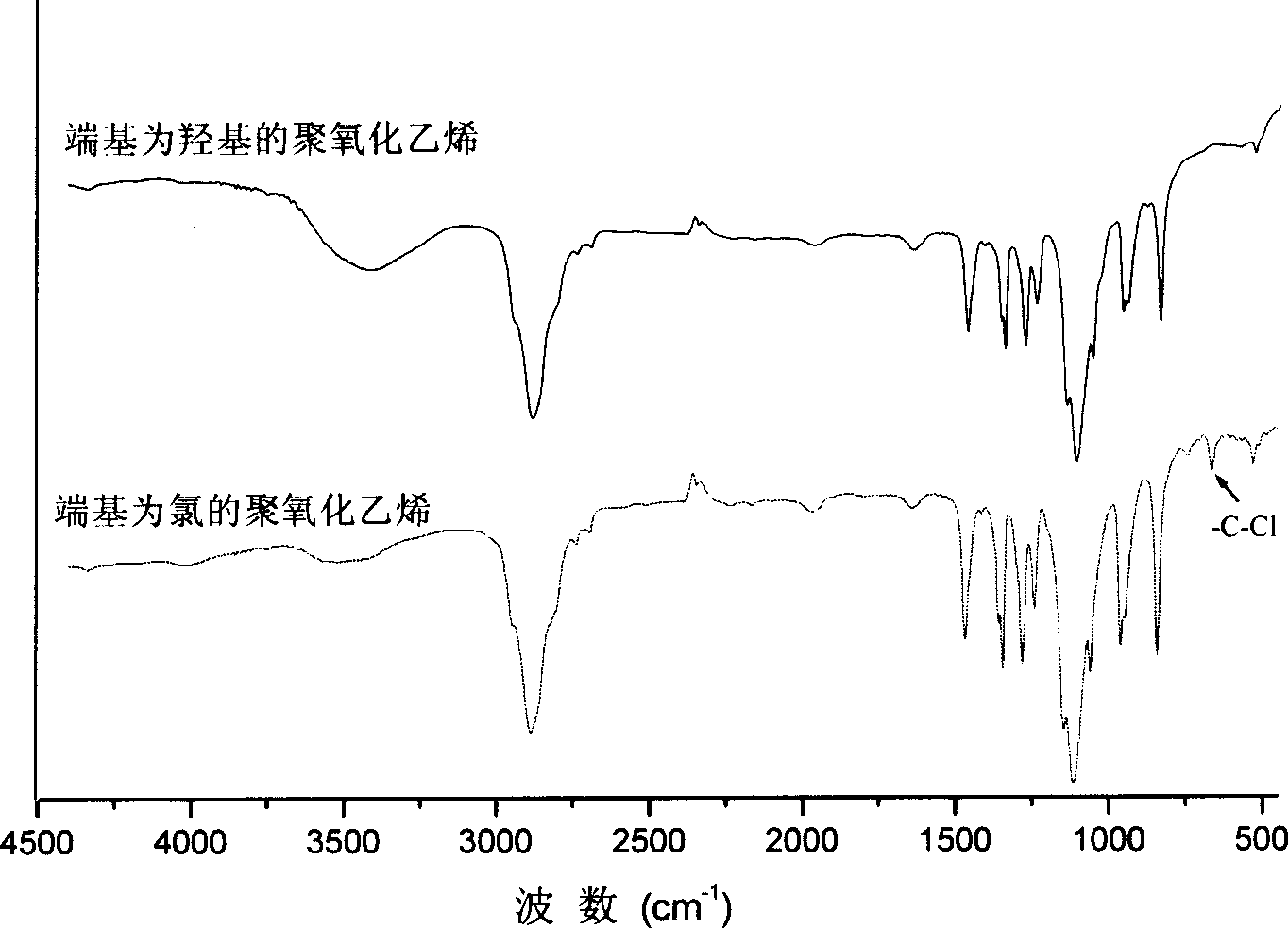

[0028] figure 1 It is the infrared spectrum comparison between the polyethylene oxide whose terminal group is chlorine and the raw material of polyethylene oxide obtained by the reaction, 667cm -1 It is the absorption peak of -C-Cl bond.

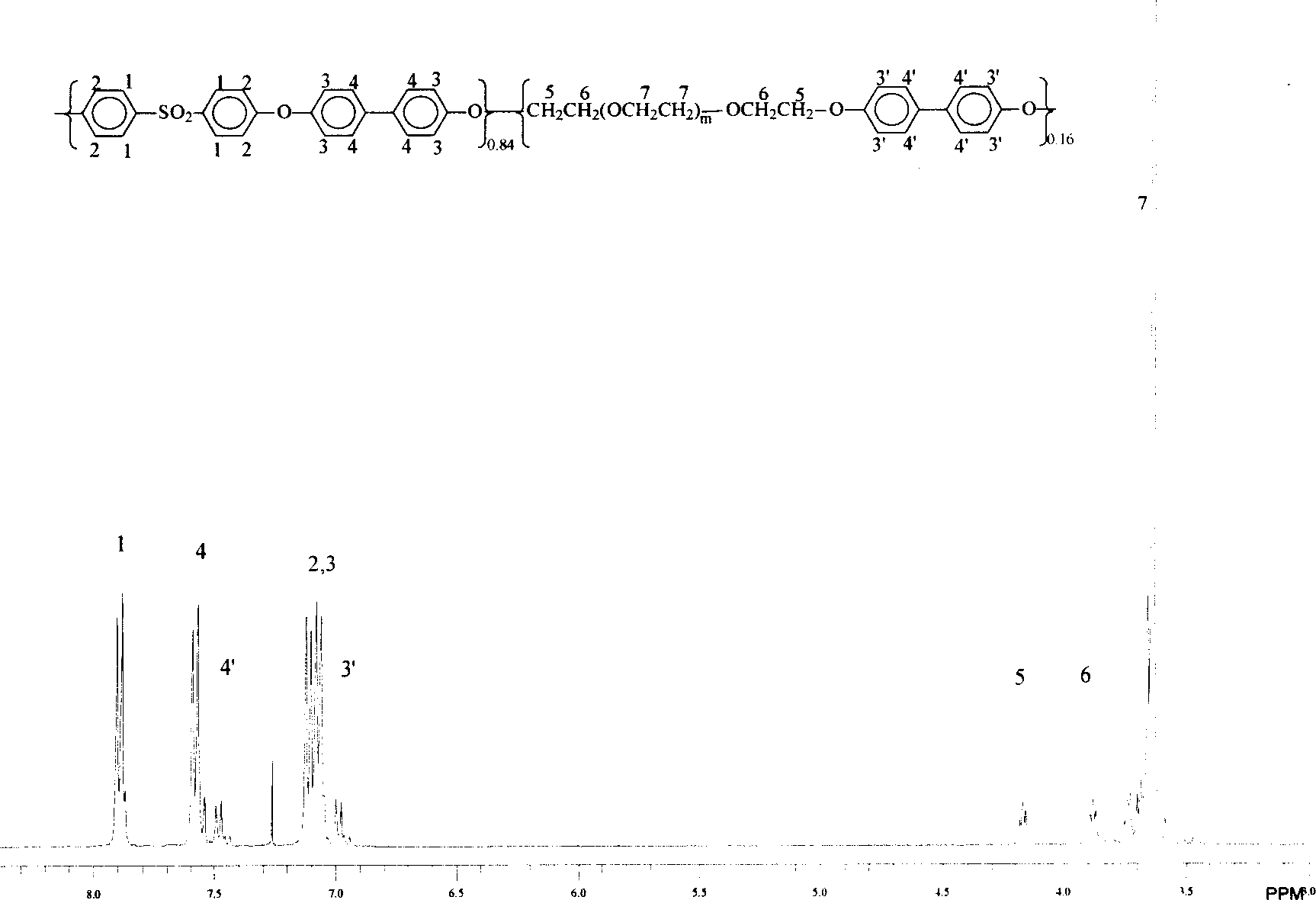

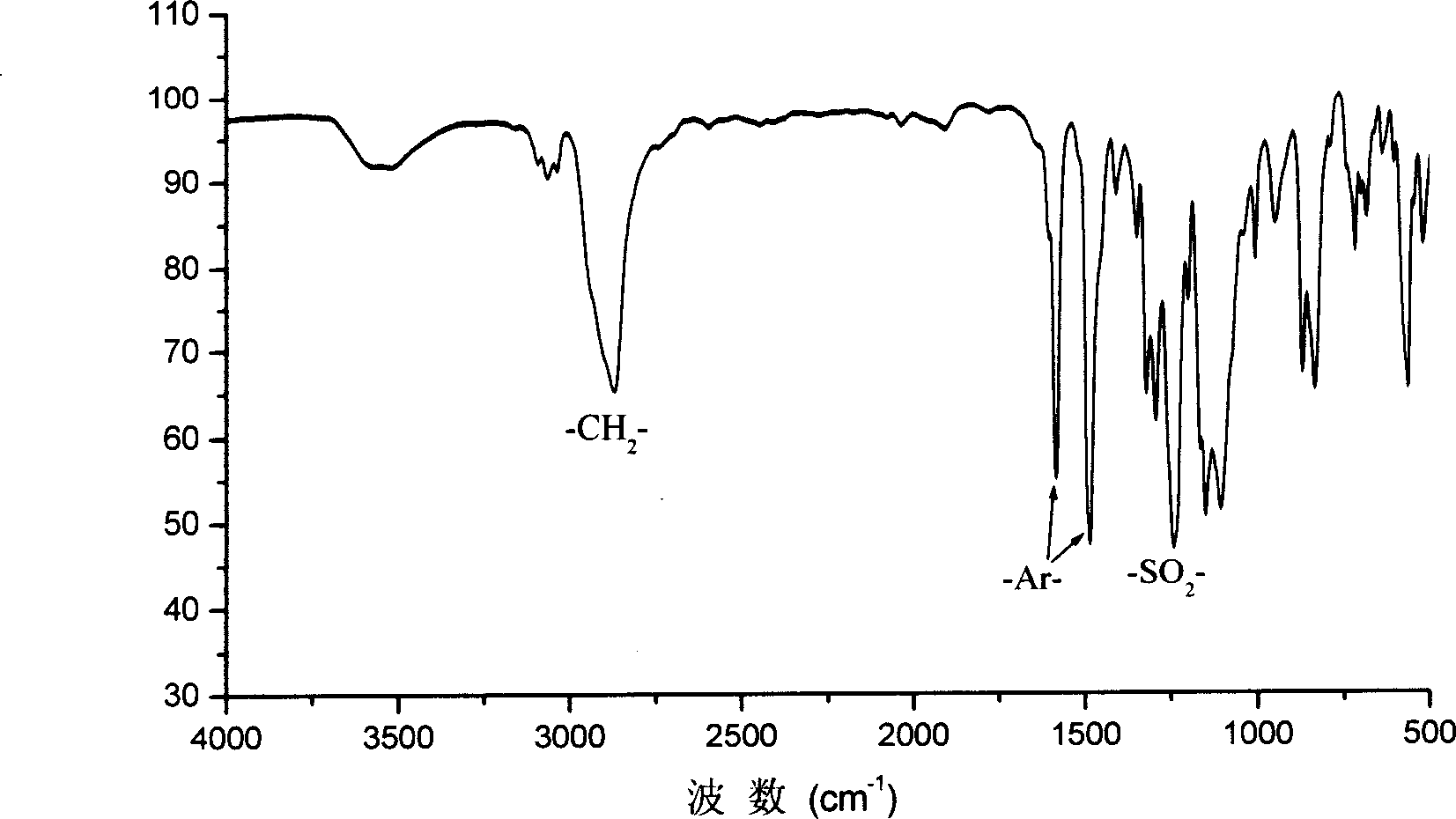

[0029] 2. Preparation of polysulfone-polyoxyethylene block copolymer with 40% polyethylene oxide content

[0030] Add 15.0g (10.0mmol) in the dry reaction bottle by the polyethylene oxide that the terminal group that makes by embodiment 1...

Embodiment 2

[0036] 1. Preparation of polyethylene oxide whose end group is a halogen atom

[0037]Add 15.0g (10.0mmol) of polyethylene oxide with a molecular weight of 1500 and 30.0mL (400.0mmol) of thionyl chloride to the dry reaction flask, and heat the reaction system to 120°C under the protection of an inert gas. And react at this temperature for 10 hours, then distill and remove the residual thionyl chloride in the reaction bottle to obtain 15.0 g of polyethylene oxide whose end group is chlorine, yield: 100%. Its infrared spectrum and figure 1 same.

[0038] 2. Preparation of polysulfone-polyoxyethylene block copolymer with 5% polyethylene oxide content

[0039] Add 15.0g (10.0mmol) to the dry reaction bottle by the polyethylene oxide that the end group that makes in the first step is chlorine, 206g (718mmol) p-chlorodiphenyl sulfone, 135.5g (728mmol) 4,4'- Dihydroxybiphenyl, 120.5g potassium carbonate, 1500mL N, N-dimethylacetamide and 200mL toluene, heated the reaction system t...

Embodiment 3

[0045] 1. Preparation of polyethylene oxide whose end group is a halogen atom

[0046] Add 15.0g (10.0mmol) of polyethylene oxide with a molecular weight of 1500 and 60.0mL (800.0mmol) of thionyl chloride to the dry reaction flask, and heat the reaction system to 150°C under the protection of an inert gas. And react at this temperature for 10 hours, then distill and remove the residual thionyl chloride in the reaction bottle to obtain 15.0 g of polyethylene oxide whose end group is chlorine, yield: 100%. Its infrared spectrum and figure 1 same.

[0047] 2. Preparation of polysulfone-polyoxyethylene block copolymer with 70% polyethylene oxide content

[0048] In the dry reaction flask, add 15.0g (10.0mmol) by the end group that the first step makes is the polyethylene oxide of chlorine, 3.293g (11.5mmol) p-chlorodiphenyl sulfone, 3.996g (21.5mmol) 4, 4'-dihydroxybiphenyl, 3.56g potassium carbonate, 70mL N, N-dimethylacetamide and 20mL toluene, the reaction system was heated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com