Process for preparing rare earth phosphate

A rare earth phosphate, rare earth inorganic salt technology, applied in the direction of phosphate, phosphorus oxyacid, rare earth metal compound, etc., can solve the problems of complex process, long time, high burning temperature, narrow particle size distribution, process and Simple equipment and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

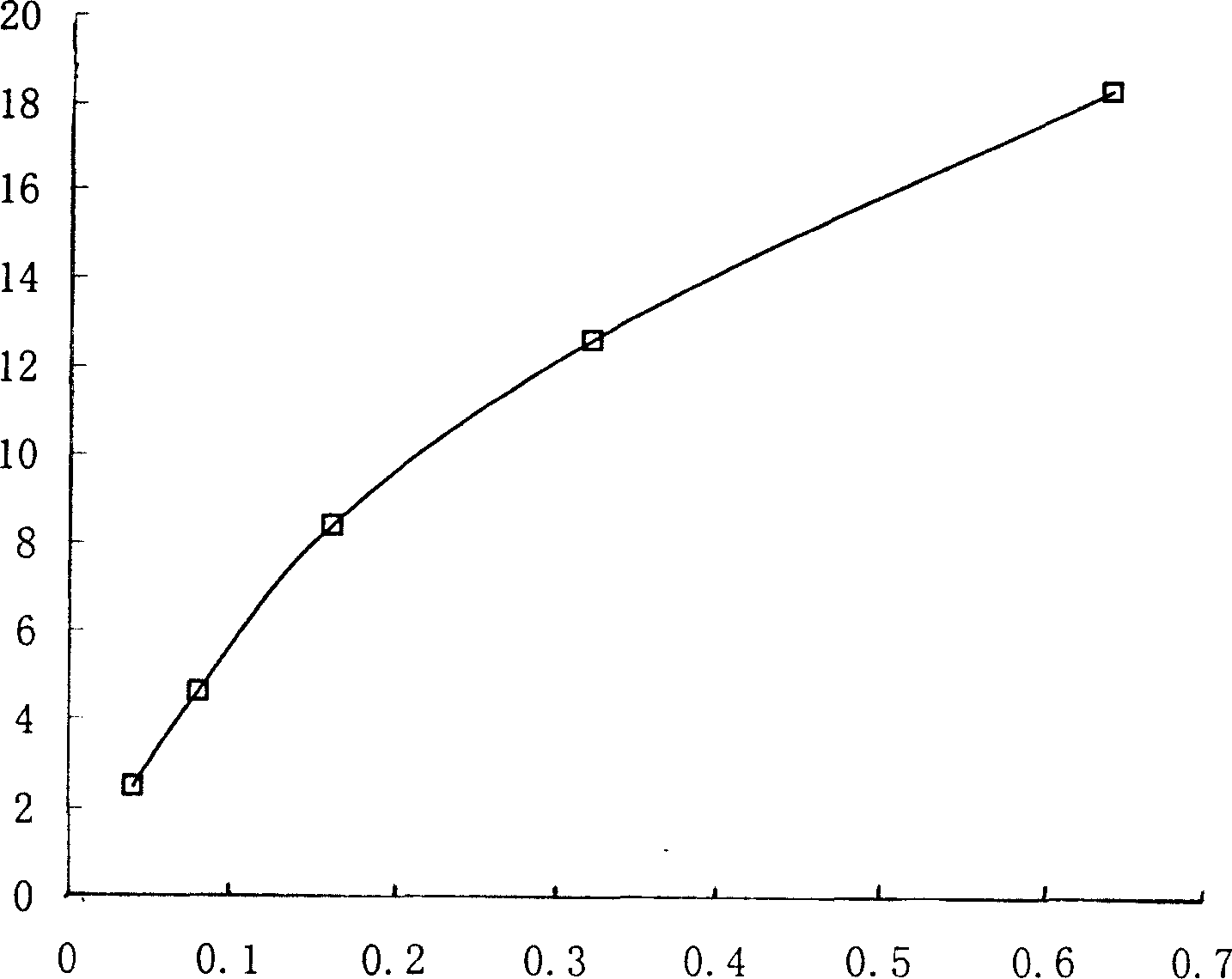

[0029] Prepare 200 milliliters of lanthanum nitrate solutions with a rare earth oxide content of 50 g / liter, and 200 milliliters of 0.5 mol / liter diammonium phosphate solutions. Under stirring, the two solutions are fed into the bottom water in parallel, and the bottom water is respectively 0.04, 0.08, 0.16, 0.32 and 0.64 mol / liter phosphoric acid aqueous solution 1000 milliliters, the feeding rate of lanthanum nitrate solution and diammonium hydrogen phosphate solution are all 20 milliliters / min. After the addition, aged at 80°C for 2 hours, filtered the resulting white precipitate, rinsed the filter cake 3 times with 20 ml of deionized water, placed the filter cake in a crucible, and heated it to 600 °C in a muffle furnace. ℃, heat preservation for 4 hours, and cooled to room temperature to obtain white lanthanum phosphate powder. The particle size was tested with a laser particle size analyzer, and the results are listed in Table 1.

[0030] Phosphoric acid concentra...

Embodiment 2

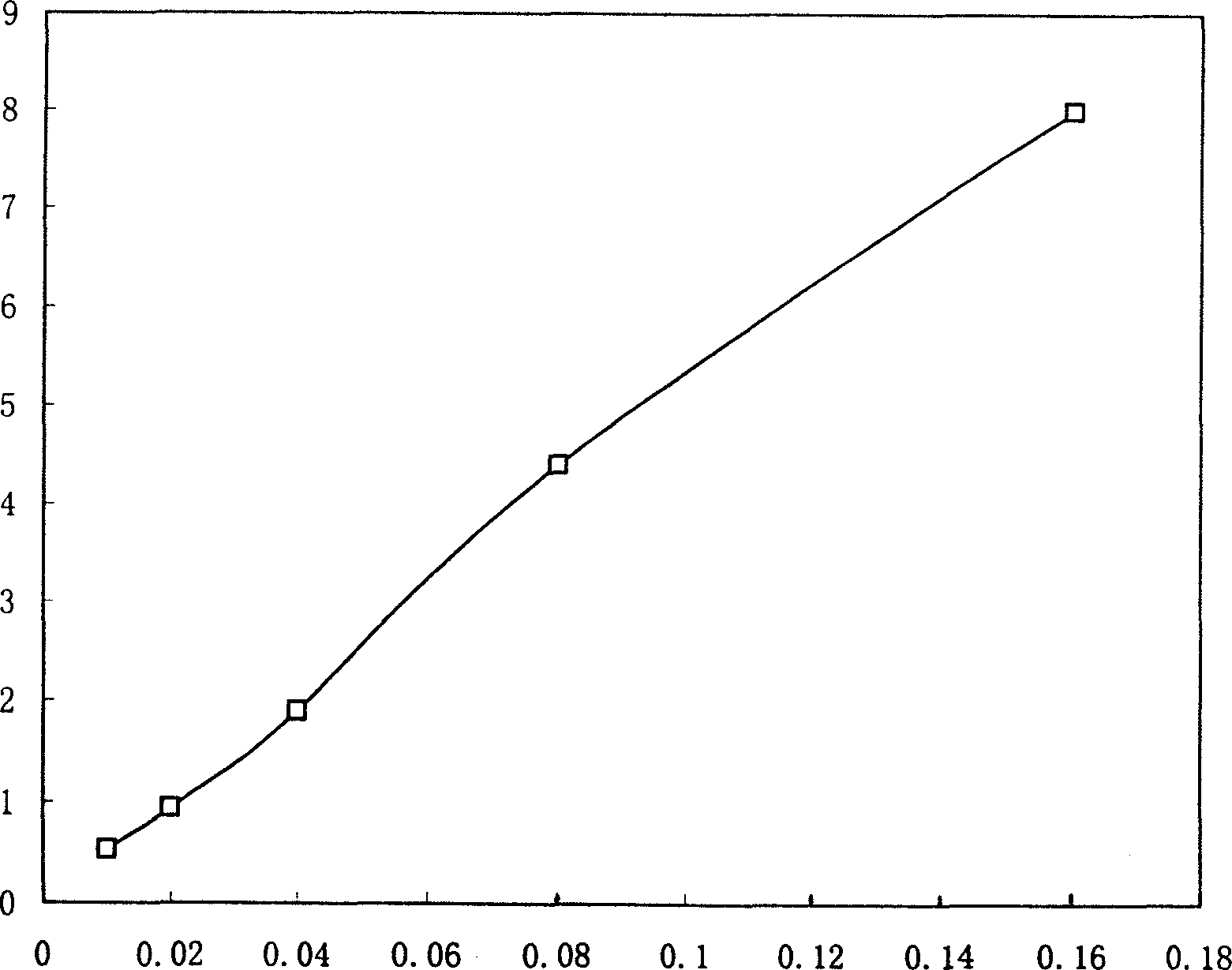

[0034] Prepare 100 milliliters of lanthanum nitrate solutions with a rare earth oxide content of 50 g / liter, and 100 milliliters of 0.5 mol / liter diammonium phosphate solutions. Under stirring, the two solutions are fed into the bottom water in parallel, and the bottom water is respectively 0.01, 50 milliliters of phosphoric acid aqueous solution of 0.02, 0.04, 0.08 and 0.16 mol / liter, the feeding rate of lanthanum nitrate solution and diammonium hydrogen phosphate solution are all 10 milliliters / min. After the addition, aged at 30°C for 6 hours, filtered the resulting white precipitate, rinsed the filter cake 3 times with 20 ml of deionized water, placed the filter cake in a crucible, and heated it to 400 °C in a muffle furnace. ℃, heat preservation for 4 hours, and cooled to room temperature to obtain white lanthanum phosphate powder. The particle size was tested with a laser particle size analyzer, and the results are listed in Table 2.

[0035] Phosphoric acid con...

Embodiment 3

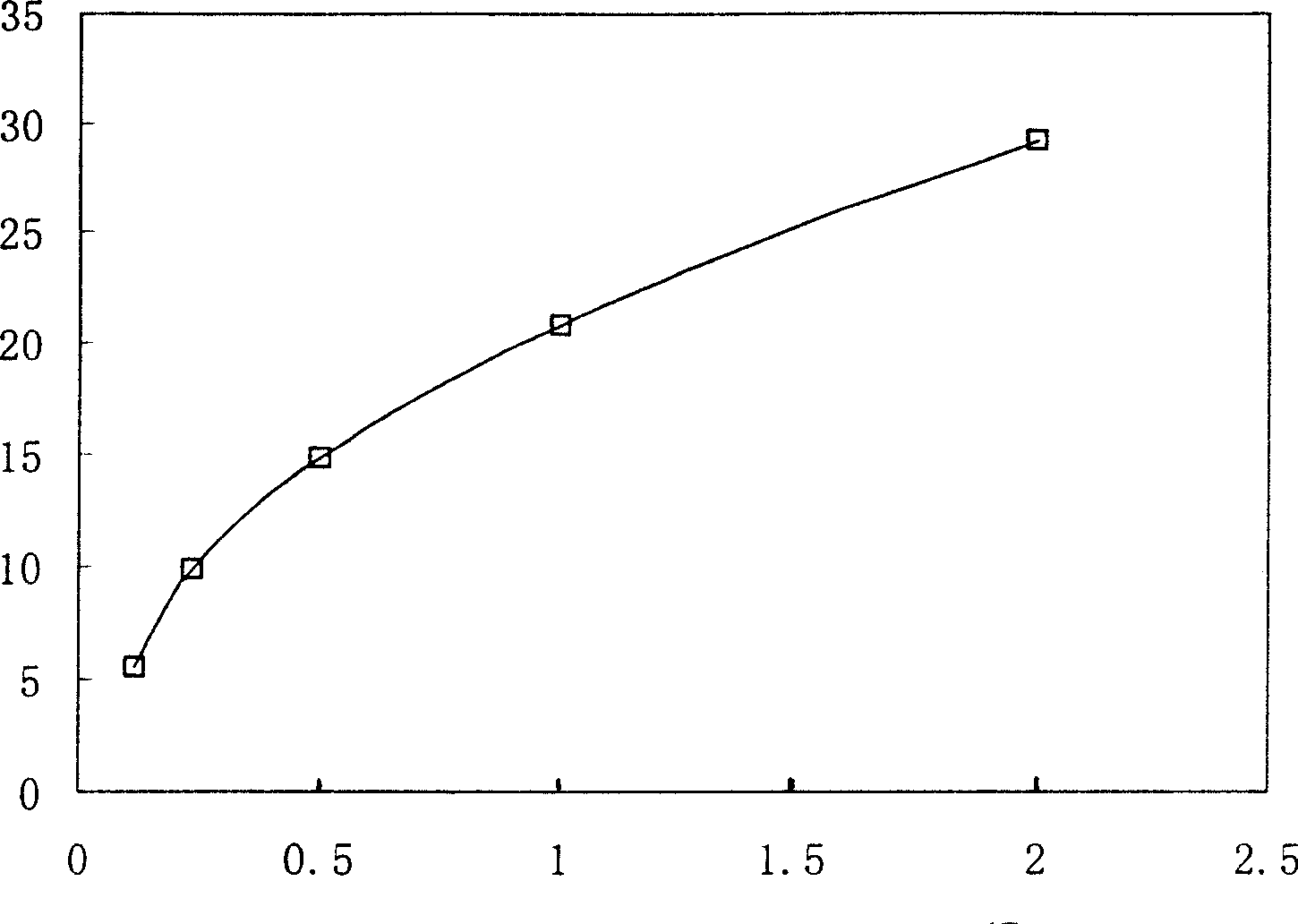

[0039] Prepare 400 milliliters of cerium nitrate solutions with a rare earth oxide content of 80 g / liter, and 400 milliliters of 1.2 mol / liter diammonium hydrogen phosphate solutions. Under stirring, the two solutions are fed into the bottom water in parallel, and the bottom water is respectively 0.12, 0.24, 0.5, 1.0 and 2.0 mol / liter phosphoric acid aqueous solution 100 milliliters, the feeding rate of cerium nitrate solution and diammonium hydrogen phosphate solution is 50 milliliters / min. After the addition, aged at 80°C for 10 hours, filtered the resulting white precipitate, rinsed the filter cake 3 times with 50 ml of deionized water, placed the filter cake in a crucible, and heated it to 700 °C in a muffle furnace. ℃, heat preservation for 4 hours, and cooled to room temperature to obtain white yellowish cerium phosphate powder. The particle size was tested with a laser particle size analyzer, and the results are listed in Table 3.

[0040] Phosphoric acid conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com