Aluminum chlorate of polymerized silicic acid and preparation method

A technology of polyaluminum chloride and iron water purifying agent, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of waste of limited natural resources, high cost, uneconomical, etc., and achieve good water purification effect and realize recycling Effects of using and solving pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

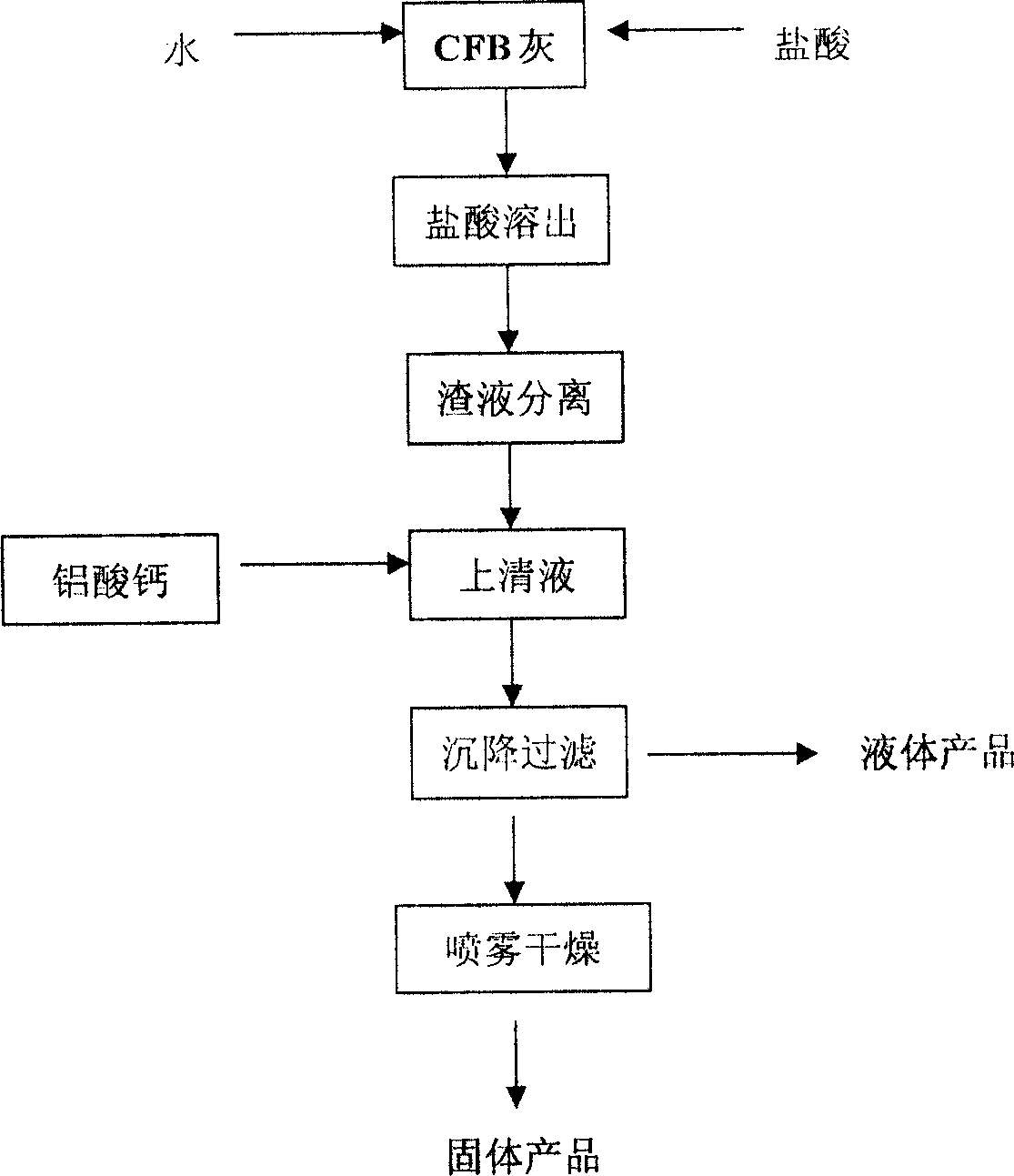

Method used

Image

Examples

Embodiment 1

[0018] Take 100 grams of circulating fluidized bed fly ash, add 300 milliliters of hydrochloric acid with a mass concentration of 30%, stir continuously at 100° C., continue acid dissolution reaction for 2 hours, and filter to obtain ferric aluminum chloride solution after hydrochloric acid dissolution reaction is completed; Take 100 ml of aluminum ferric chloride solution, heat it and keep stirring. When the temperature reaches 85°C, add 9 grams of calcium aluminate powder one after another. After reacting for 1 hour, settle the material and filter it to separate the solid and liquid, and then you can get the polymerized chloride Aluminum and iron liquid products are dried to obtain solid products.

Embodiment 2

[0020] Get 100 grams of circulating fluidized bed fly ash, add 350 milliliters of hydrochloric acid with a mass concentration of 22.5%, stir continuously at 100° C., and continue the acid dissolution reaction for 2 hours. After the hydrochloric acid dissolution reaction finishes, filter to obtain ferric aluminum chloride solution; 100 ml of ferric aluminum chloride solution, heated and stirred continuously, when the temperature reached 85°C, 12 grams of calcium aluminate powder was added successively, and after reacting for 1 hour, the material was settled and filtered to separate the solid and liquid to obtain polyaluminum chloride The iron liquid product is dried to obtain a solid product.

Embodiment 3

[0022] Take circulating fluidized bed fly ash 100 grams, add mass concentration and be 400 milliliters of hydrochloric acid of 10%, under 100 ℃ of conditions, constantly stir, continuous acid dissolution reaction is 2 hours, after hydrochloric acid stripping reaction finishes, filter and obtain ferric chloride solution; 100 ml of ferric aluminum chloride solution, heating and stirring constantly, when the temperature reaches 85°C, add 15 grams of calcium aluminate powder one after another, and after reacting for 1 hour, settle and filter the material to separate solid and liquid to obtain polyaluminum chloride The iron liquid product is dried to obtain a solid product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com