Method for preparing high-curing modified-guar-gum contained aqueous solution

A technology with high solid content and aqueous solution, which is applied in the direction of water-repellent addition, inorganic compound addition, paper, etc. It can solve the problems of difficult control of viscosity, slow dissolution rate, and high content of water-insoluble substances, so as to achieve low viscosity, improve production efficiency, The effect of high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

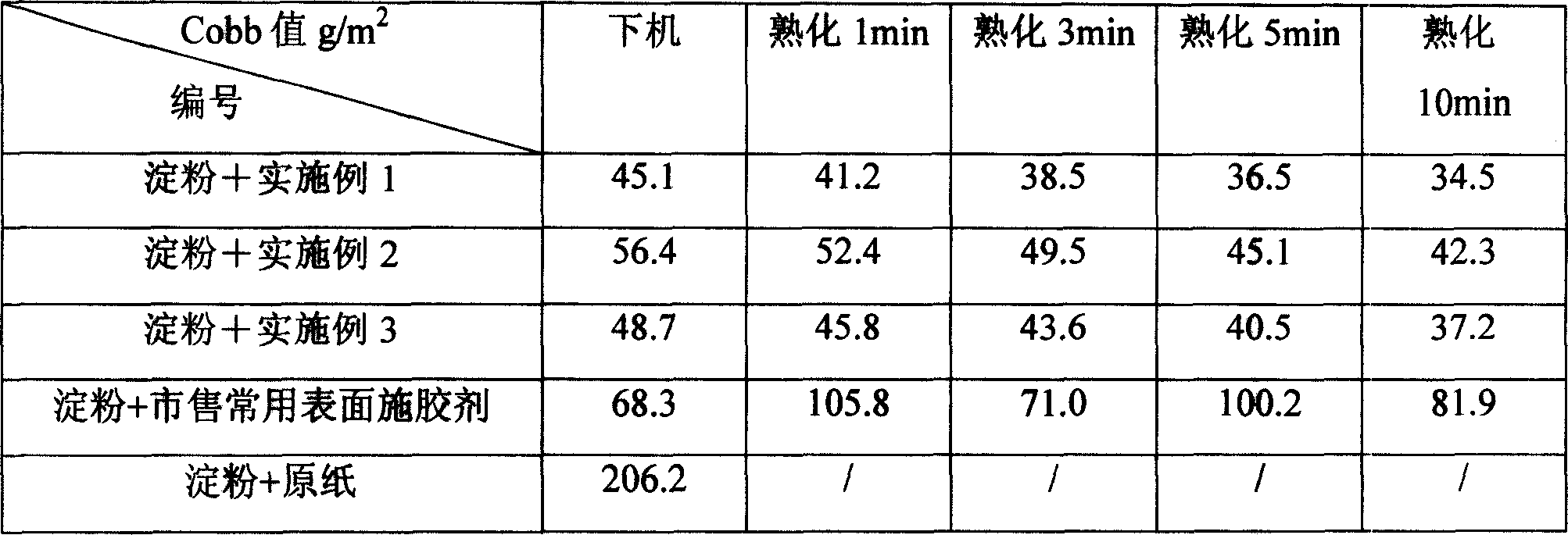

Examples

Embodiment 1

[0025] 82.5 grams of water are added in a 500ml four-necked round-bottomed flask, 15 grams of cationic guar gum powder (water content 10%) are dispersed therein under electric stirring, 5 grams of 5% sodium acetate buffer solution is added, the pH of the system is 7.6, and 10 gram mannase (1000IU / g, solid content is 10%), then add 5 grams (90IU / g, solid content is 10%) galactose oxidase, be warming up to 50 degree of reaction 6 hours under stirring, after Raise the temperature to 90°C and keep it warm for 50 minutes, then cool down to 25°C to obtain a light yellow transparent liquid. The solid content is 11%, the viscosity is 500mpa.s, and the viscosity is measured by NDJ-1 type rotational viscometer according to ISO 2884-2-2003.

[0026] Cationic guar gum powder adopts CG-40, a product of Shanghai Gaowei Chemical Co., Ltd.;

[0027] Mannosidase using PuraBrite from GENENCOR INTERNATIONAL INC. TM , the activity unit is 1000IU / g, and the solid content is 10-12%;

[0028] The...

Embodiment 2

[0030] Add 114 grams of deionized water into a 500ml four-necked round bottom flask, turn on electric stirring, disperse 18 grams of hydroxypropyl guar gum powder (water content 10%) wherein, add 5 grams of 5% calcium acetate buffer solution, the pH of the system is 7 .3, add 15 grams of mannase (1000IU / g, solid content is 10%), then add 20 grams of galactose oxidase (90IU / g, solid content is 10%), be warming up to 40 degrees of reaction under stirring Hours, then raise the temperature to 90°C and keep it warm for 30 minutes, then cool down to 25°C to obtain a light yellow transparent liquid. The solid content is 15.0%, the viscosity is 200mpa.s, and the viscosity is measured by NDJ-1 type rotational viscometer according to ISO 2884-2-2003.

[0031] Hydroxypropyl guar gum is the Jaguar8060 of Rhodesia Company, and other raw materials are with embodiment 1.

Embodiment 3

[0033] Add 110 grams of deionized water into a 500ml four-necked round-bottomed flask, turn on electric stirring, disperse 7 grams of hydroxypropyl guar gum powder and 8 grams of cationic guar gum powder (water content 10%), add 5 grams of 5% phosphoric acid Sodium hydrogen disodium buffer solution, the pH of the system is 7.8, add 10 grams of mannase (1000IU / g, solid content is 10%), then add 5 grams of galactose oxidase (90IU / g, solid content is 10%) , heated to 50 degrees under stirring for 6 hours, then raised to 95 degrees and kept for 10 minutes, and then cooled to below 30 degrees to obtain a light yellow transparent liquid. The solid content is 10.5%, the viscosity is 356mpa.s, and the viscosity is measured by NDJ-1 type rotational viscometer according to ISO 2884-2-2003.

[0034] The source of raw materials is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com