Nano periodic mesoporous organic silicon oxide material and its synthetic method and its use

A technology of organic silicon oxide and synthesis method, which is applied in the direction of producing hydrocarbons from halogen-containing organic compounds, chemical instruments and methods, catalyst carriers, etc., can solve problems such as high cost, limited organic solubility, environmental pollution, etc., to prevent pollution Effect of reducing solubility limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

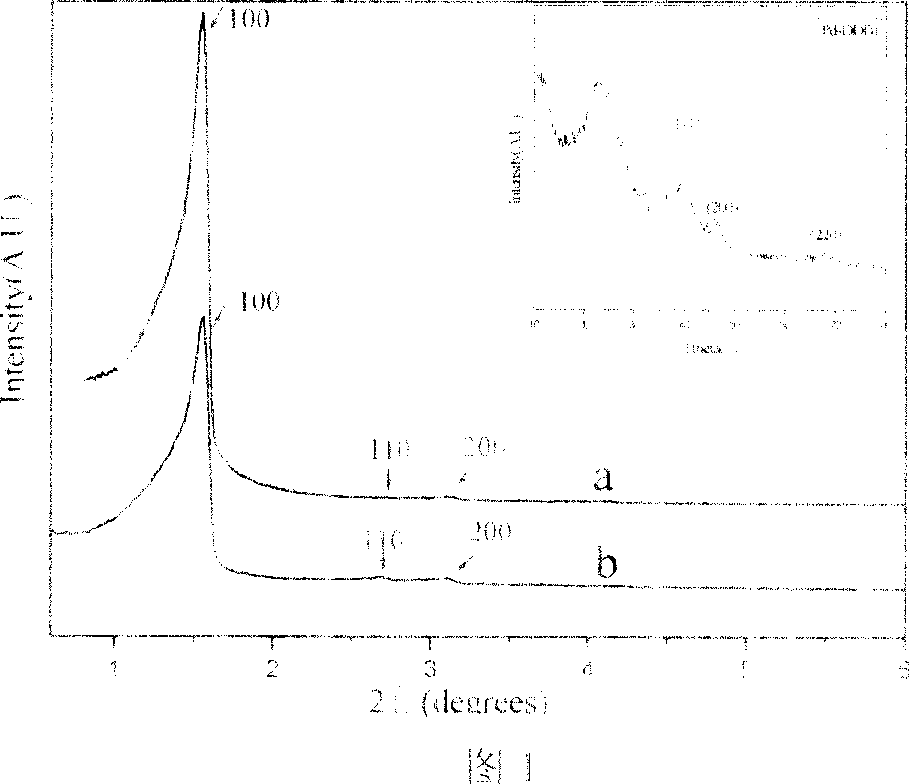

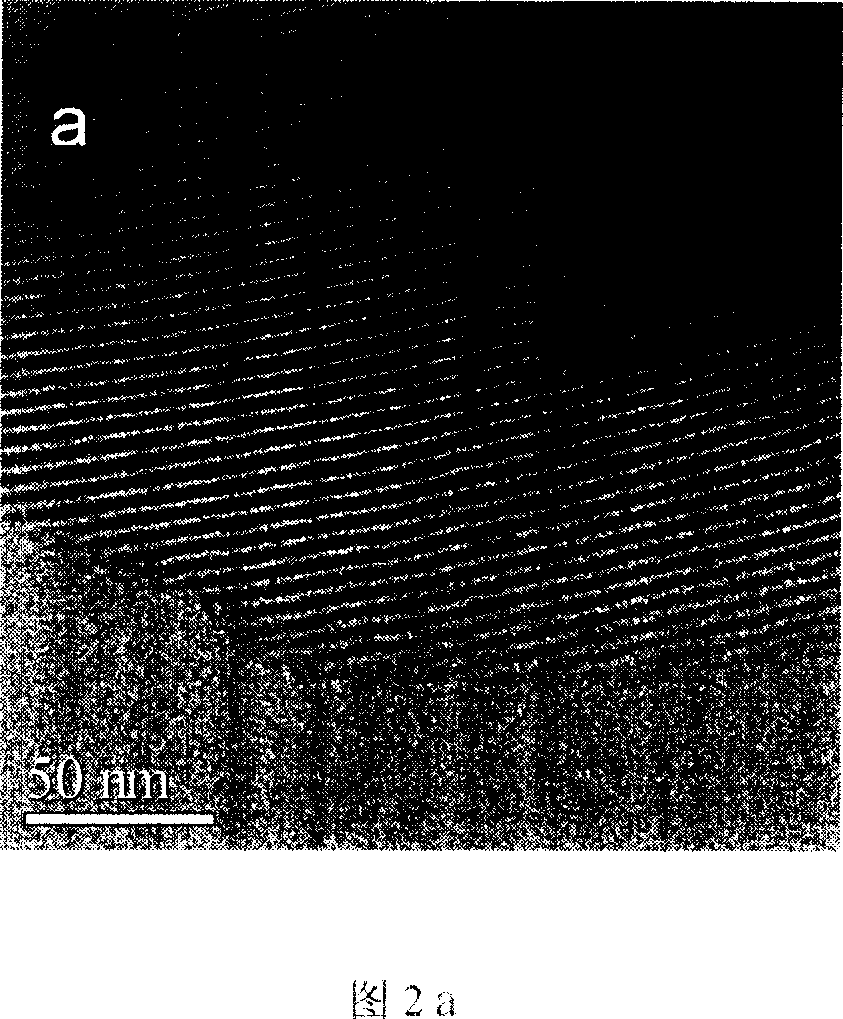

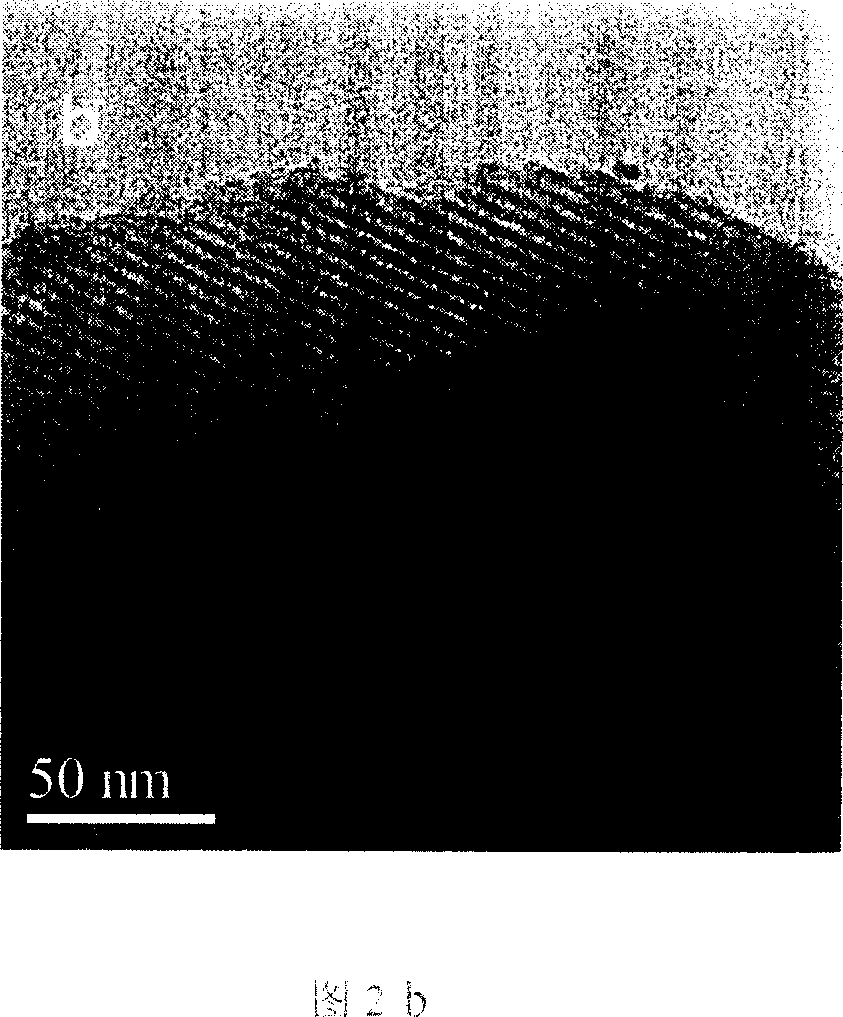

[0033] Surfactant Brij76[C 18 h 37 (OCH 2 CH 2 ) 10 OH], Silicone BTEB[(C 2 h 5 O) 3 Si-C 6 h 4 -Si(OC 2 h 5 ) 3 , hydrochloric acid (HCl) and water at room temperature in the following molar ratio Brij76: H 2 O:HCl:BTEB=0.11:222:3.2:0.56 mixed. Specifically, Brij 76, H 2 O and HCl were pre-stirred at 323K for 12 hours, then BTEB was added to continue stirring for 12 hours, and then hydrothermally aged at 363K for 24 hours. After filtration, washing, and vacuum drying at 373K for 10 hours, the surfactant (350 mL / g) was extracted with 1M HCl / ethanol solution, washed with absolute ethanol, and finally the PMO material DDB1 was obtained in vacuum for 10 hours. With 0.12ml of 0.05g / mL PdCl 2Immerse 0.1g carrier in aqueous solution for 24h, dry in 373K oven, use 10V%H at 473K 2 / N 2 The Pd / DDB1 catalyst was prepared by reduction activation for 3h. 0.1g catalyst was added to the mixture containing 0.1mL iodobenzene (PhI), 2mL water, and 0.22g HCOONa (reducing agent...

Embodiment 2

[0035] Orthoethylsilicate (TEOS), cetyltrimethylammonium bromide (CTAB), sodium hydroxide (NaOH), phenyltrimethoxysilane (PTES) and water at room temperature in the following molar ratio: CTMABr :NaOH:Si:H 2 O=0.12:0.5:1.0:130, wherein Si is TEOS, stirred for 24h, filtered, washed, dried in vacuum at 100°C for 10h, then extracted the surfactant with 1M HCl / ethanol solution, washed with absolute ethanol, and finally Ph-MCM-41 was obtained in vacuum for 10 hours. with 1.8ml of 1.67wt% PdCl 2 Immerse the carrier in the aqueous solution for 24 hours, dry it in a 373K oven, and use 10V%H at 200°C 2 / N 2 The Pd / Ph-MCM-41 catalyst was prepared by reduction activation for 3h. The iodobenzene Ullmann reaction was carried out in a 50 mL round bottom flask equipped with a condenser. Mix 0.91g of iodobenzene (PhI), 10mL of water, 0.5g of catalyst, 1.10g of HCOONa (reducing agent) and 1.4g of KOH, and reflux at a constant temperature of 373K for 10h under electromagnetic stirring. Th...

Embodiment 3

[0037] Orthoethylsilicate (TEOS), cetyltrimethylammonium bromide (CTAB), sodium hydroxide (NaOH), phenyltrimethoxysilane (PTES) and water at room temperature in the following molar ratio: CTMABr :NaOH:Si:H 2 O=0.12:0.5:1.0:130, wherein Si=TEOS+PTES, PTES:TEOS=3:7 mixed, stirred for 24h, filtered, washed, vacuum dried at 373K for 10h, and then extracted with 1M HCl / ethanol solution for surface activity agent, then washed with absolute ethanol, and finally obtained Ph-MCM-41 in vacuum for 10 hours. With 1.8ml of 1.67wt% PdCl 2 Immerse the carrier in the aqueous solution for 24 hours, dry it in a 373K oven, and use 10V%H at 473K 2 / N 2 The Pd / Ph-MCM-41 catalyst was prepared by reduction activation for 3h. The iodobenzene Ullmann reaction was carried out in a 50 mL round bottom flask equipped with a condenser. Mix 0.91g of iodobenzene (PhI), 10mL of water, 0.5g of catalyst, 1.10g of HCOONa (reducing agent) and 1.4g of KOH, and reflux at a constant temperature of 373K for 10h ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com