Preparation method of metal icosahedral nanoparticles

An icosahedron and nanoparticle technology, which is applied in the field of preparation of metal nanomaterials, can solve the problems of poor reproducibility of the preparation process, complicated preparation process, not conforming to green chemistry, etc., and achieves reduced preparation cost, high yield, easy effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

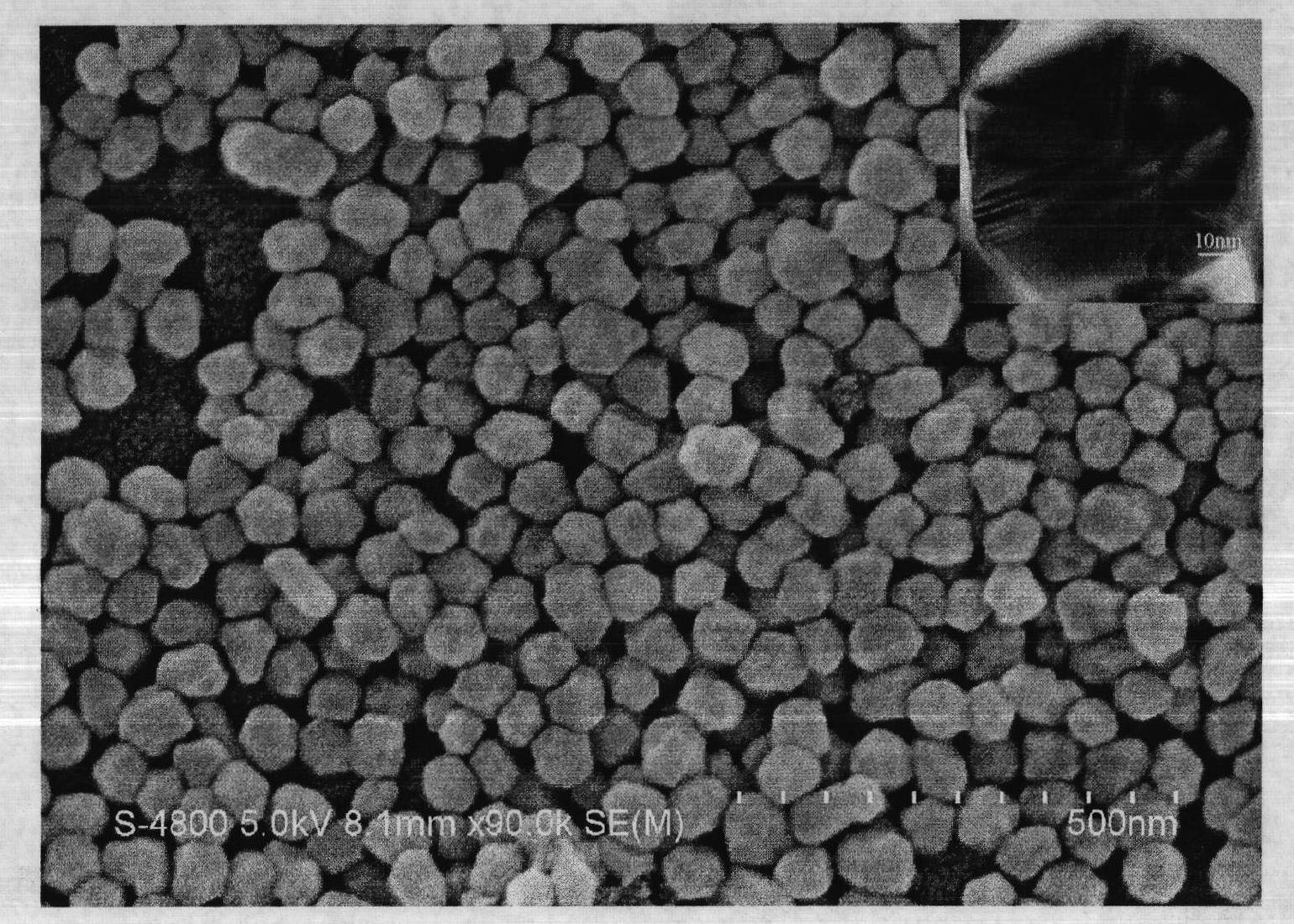

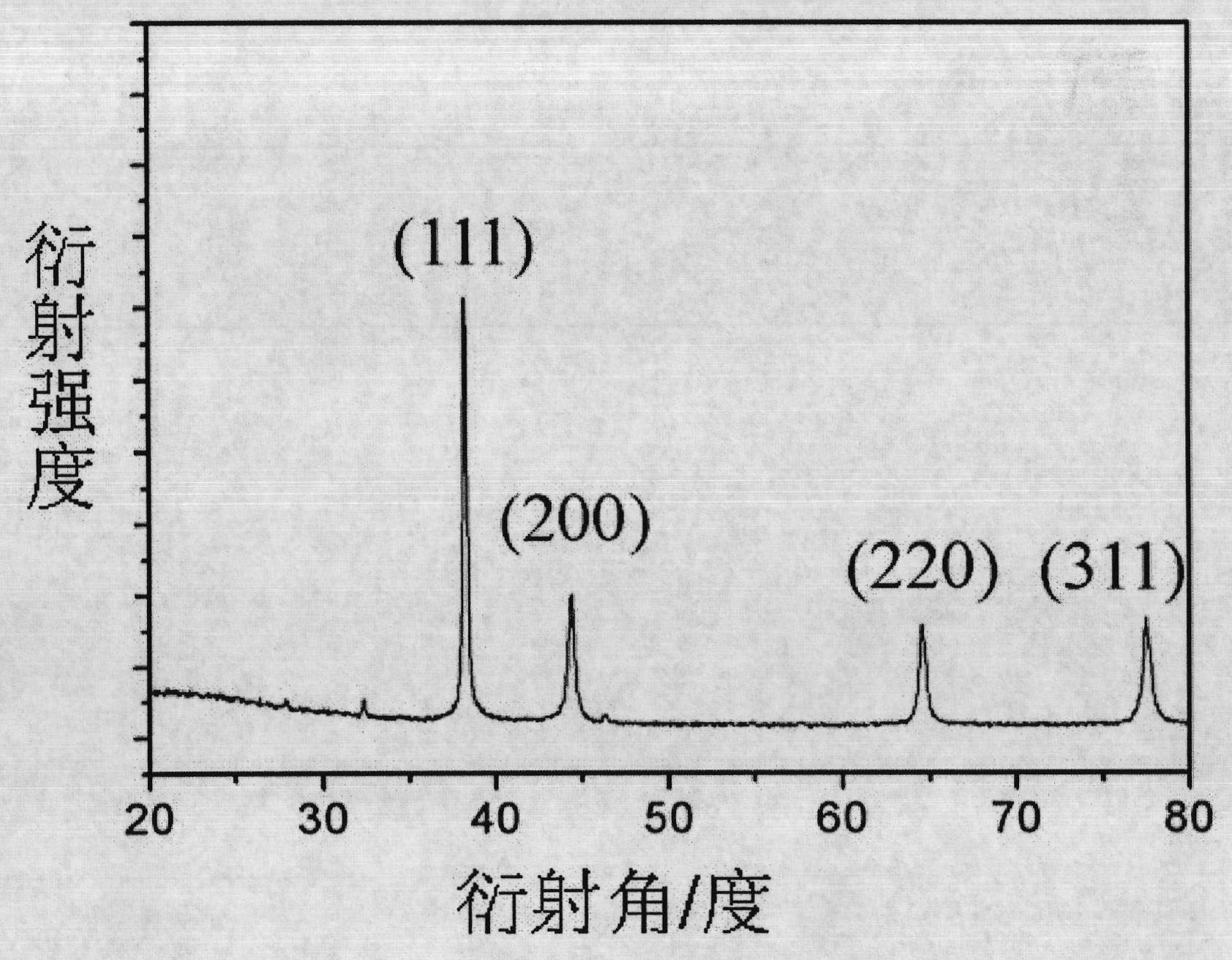

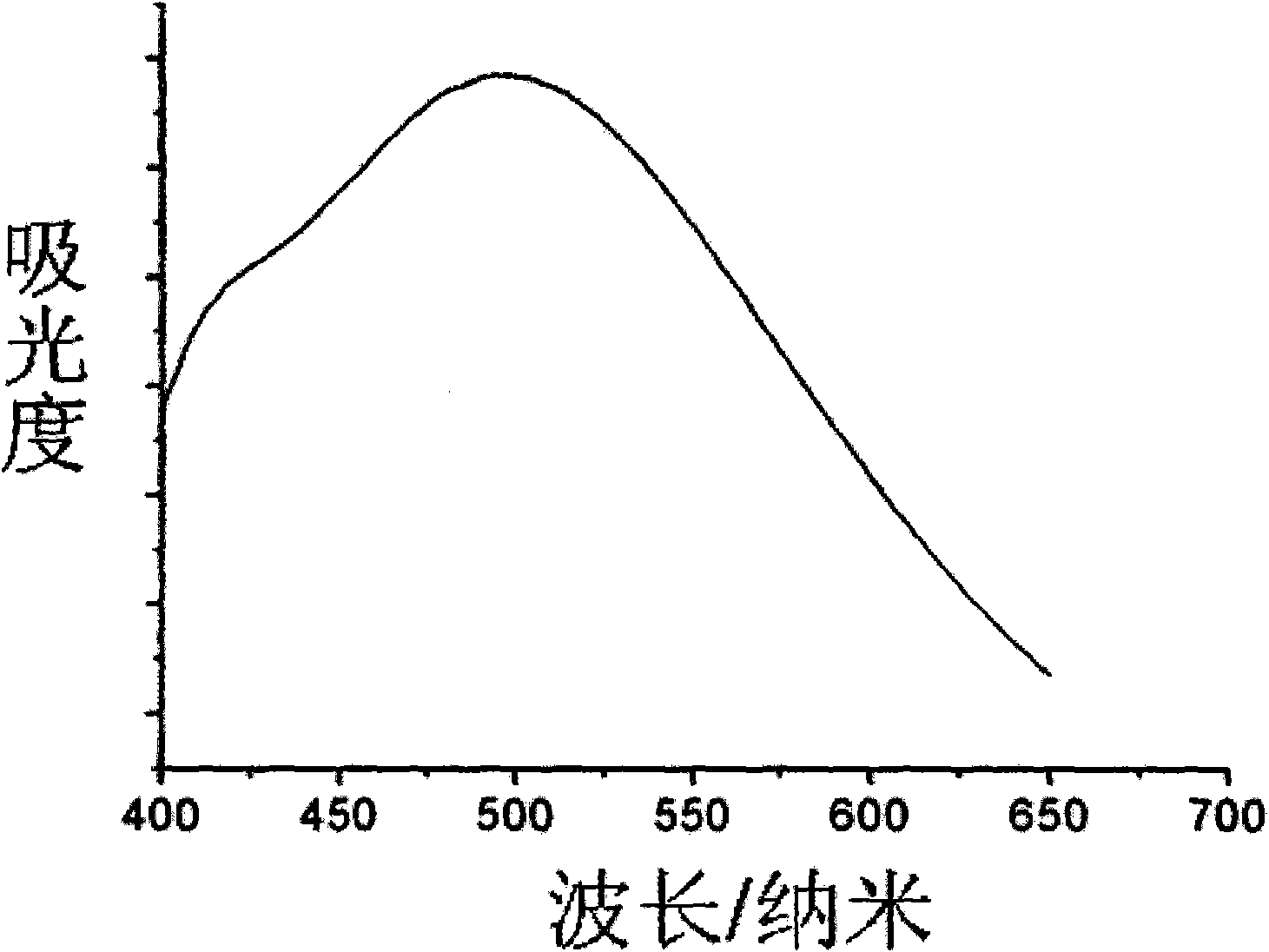

[0017] Measure 10mL of 0.02mol / L silver nitrate aqueous solution, add 0.1g of polyvinylpyrrolidone, and stir well. Measure 5 mL of 2% (weight concentration) ammonia water, add to the above solution, and stir for 15 minutes. Then the above mixed solution was transferred to a 25mL polytetrafluoroethylene-lined stainless steel reaction kettle and sealed. React in an oven at 120° C. for 10 hours. Cool at room temperature, centrifuge, collect the precipitate, and wash twice with distilled water and absolute ethanol respectively to obtain silver icosahedral nanoparticles with a particle size of 60-80nm.

Embodiment 2

[0019] Measure 10mL of 0.025mol / L silver nitrate aqueous solution, add 0.2g of polyvinylpyrrolidone, and stir well. Measure 5mL of 2% ammonia water, add to the above solution, and stir for 20 minutes. Then the above mixed solution was transferred to a 25mL polytetrafluoroethylene-lined stainless steel reaction kettle and sealed. React in an oven at 140°C for 6 hours. Cool at room temperature, centrifuge, collect the precipitate, and wash twice with distilled water and absolute ethanol respectively to obtain silver icosahedral nanoparticles with a particle size of 50-70nm.

Embodiment 3

[0021] Measure 10mL of 0.03mol / L silver nitrate aqueous solution, add 0.4g of polyvinylpyrrolidone, and stir well. Measure 8 mL of 2% ammonia water, add to the above solution, and stir for 15 minutes. Then the above mixed solution was transferred to a 25mL polytetrafluoroethylene-lined stainless steel reaction kettle and sealed. React in an oven at 120°C for 7 hours. Cool at room temperature, centrifuge, collect the precipitate, and wash twice with distilled water and absolute ethanol respectively to obtain silver icosahedral nanoparticles with a particle size of 40-60nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com