Method for separately leaching out low temperature pressed cotton seed kernel cake with No.6 solvent oil and ethynol

A technology of pressing cake and solvent oil, which is applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc. It can solve the problem of increasing the loss of No. 6 solvent oil, difficulty in ensuring the residual oil rate of degreased cotton meal, and increasing heat energy consumption, etc. problems, achieving significant economic and social benefits, beneficial to solvent recovery, and short degreasing and leaching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

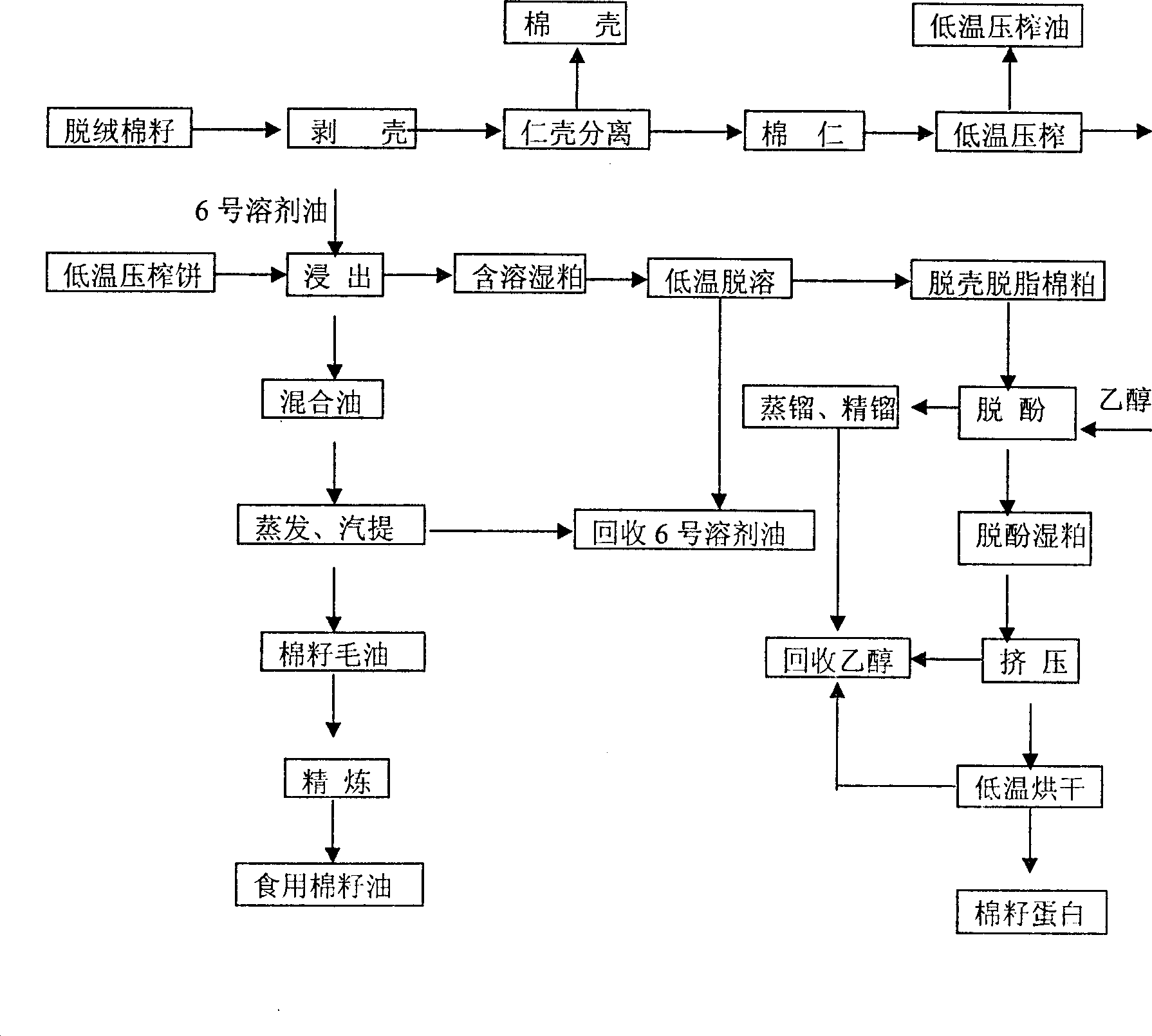

[0014] Embodiment 1: The light cottonseed after develvet is shelled by the shelling unit and separated from the kernel and shell to obtain cotton kernel and cotton shell. The shell content rate in the kernel is 8%, and the kernel content rate in the shell is <1%. Use a low-temperature screw oil press (the low-temperature screw oil press shown in Chinese patent ZL02290849.8 can be used), and press the oil at a low temperature of 50°C to obtain a cotton kernel low-temperature pressed cake with a residual oil rate of 14%. and cotton kernel low-temperature pressed oil; the cotton kernel low-temperature pressed cake is extracted with No. 6 solvent oil in the first extractor, the extraction temperature is 50°C, the solvent ratio is 1:1, and the extraction time is 90 minutes. The mixed oil is evaporated, After stripping, cottonseed crude oil is obtained, and then refined to obtain edible cottonseed oil, which contains soluble wet cypress, and is passed through a low-temperature desolv...

Embodiment 2

[0015] Example 2: The shell rate in the kernel is 10%, and the oil is squeezed at a low temperature at a temperature of 35°C to obtain a cotton kernel low-temperature pressed cake with a residual oil rate of 16%, and the extraction temperature of oil is extracted with No. 6 solvent oil 55°C, the solvent ratio is 1.2:1, the leaching time is 120 minutes, and the residual oil rate of the degreased cottonwood obtained by low-temperature precipitation at a temperature lower than 80°C is 1.5%, the water content is 7.5%, and the concentration is 95%. % ethanol at 50°C with a solvent ratio of 1.3:1 for 110 minutes for leaching and dephenolization, and the dephenolized wet meal after draining is extruded by an extruder to extrude part of the ethanol leachate, and then dried at low temperature. When the temperature is 80°C, the protein content is 53%, the residual oil rate is 1.2%, the free gossypol is less than 0.045%, and the residual soluble cottonseed protein is less than 500ppm. Dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com