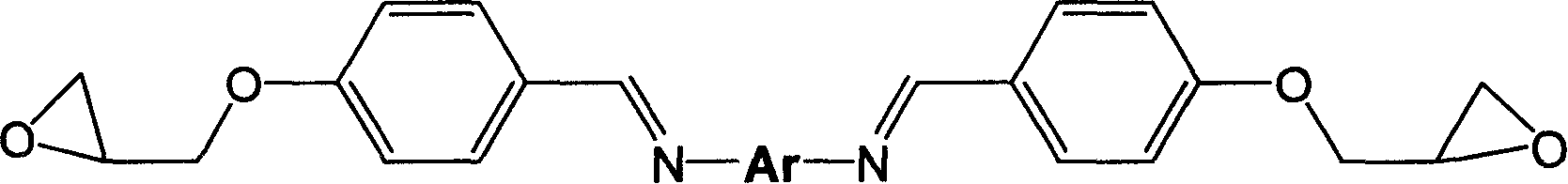

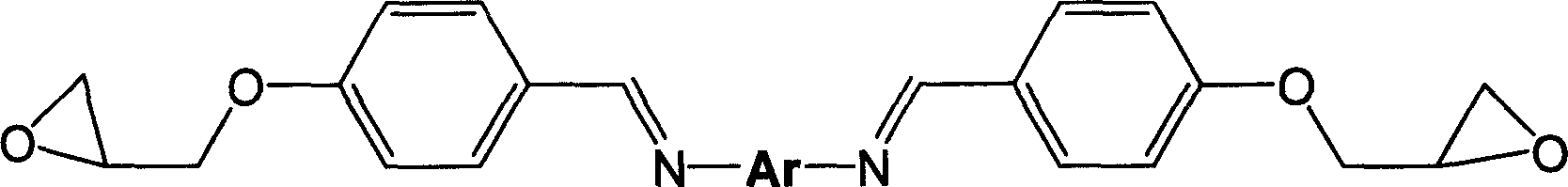

Schiff's base type epoxy resin of liquid crystal, preparation method and application

A technology of epoxy resin and Schiff base, which is applied in the direction of liquid crystal materials, chemical instruments and methods, etc., to achieve the effects of convenient preparation, wide range of liquid crystals, excellent heat resistance and dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

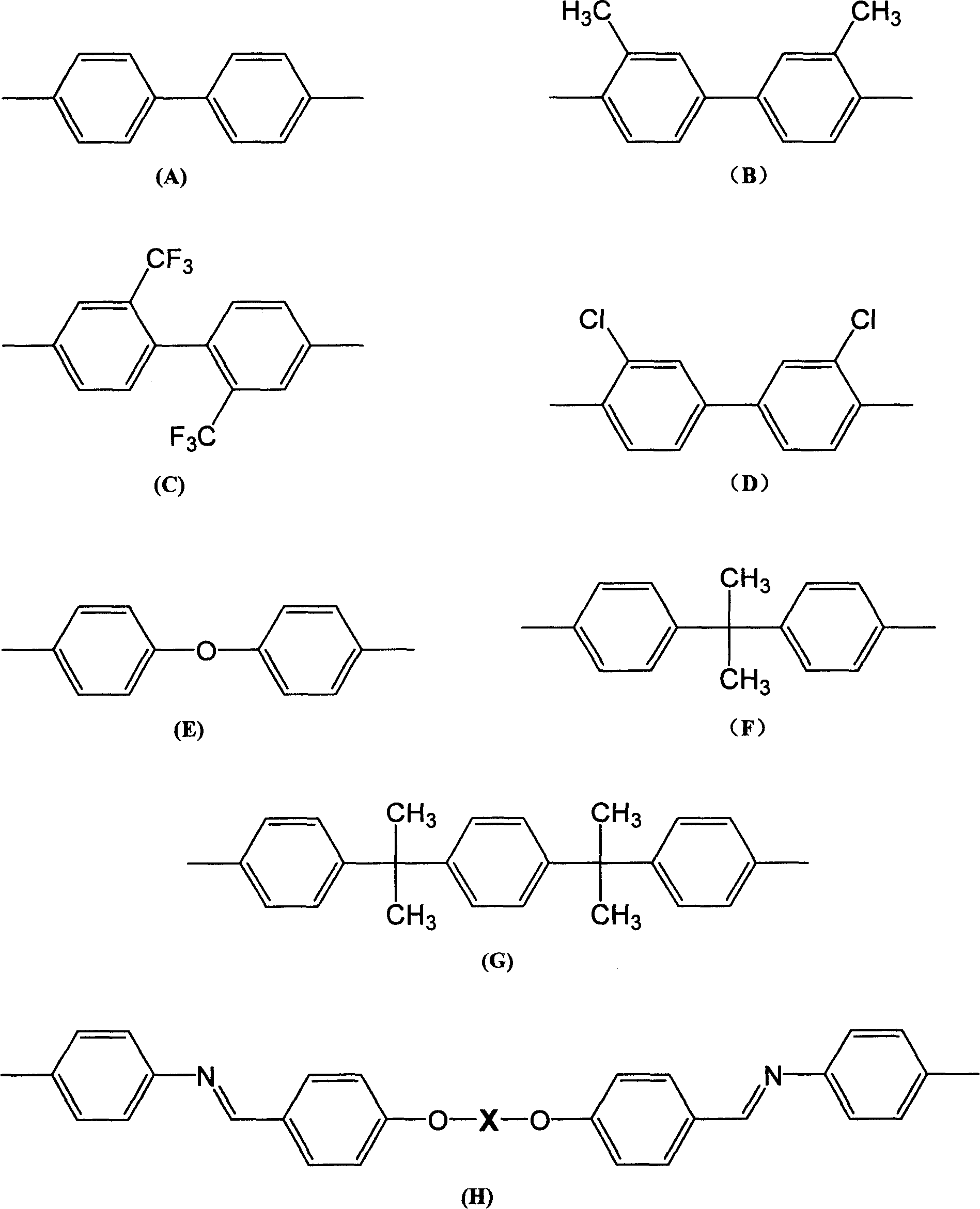

Method used

Image

Examples

Embodiment 1

[0026] In a reaction flask equipped with a thermometer, condenser and stirrer, add 1mol of 3,3'-dimethylbenzidinediamine, 2mol of p-hydroxybenzaldehyde and 2000mL of ethanol, heat to 70°C, and slowly add a small amount of Acetic acid, reflux reaction for 8 hours. After the reaction was completed, most of the ethanol was distilled off, cooled and crystallized, and filtered to obtain a hydroxyl-terminated compound (yield: 95%).

[0027]In another reaction flask equipped with a thermometer, a constant flow pump, a stirrer, a water separator and a vacuum system, add 1 mol of the hydroxyl compound obtained above and 1000 mL of epichlorohydrin, and stir to dissolve; Add 150g concentration of 50% sodium hydroxide aqueous solution, the reaction temperature is kept at 60°C, the pressure is kept at -0.09MPa, and the water in the reaction system is taken out by azeotropy. Remove insoluble matter by filtration, and remove unreacted epichlorohydrin under reduced pressure. Then add 600mL ...

Embodiment 2

[0029] 1 part of liquid crystal epoxy resin of Example 1, 1 part (mol) of DDS curing agent, heated and melted at 150° C. and mixed uniformly. Pre-cure at 160°C for 4 hours followed by post-cure at 180°C for 5 hours. The dielectric constant of the obtained cured product can reach 2.1 (60Hz, ASTM D150), and the glass transition temperature can reach 212°C (DSC). It can be used to prepare electronic packaging materials.

Embodiment 3

[0031] (1) Synthesis of 4-(4-hydroxybenzylidene imino) aniline reference (Vasile Cozan, Ecaterina Avram, European Polymer Journal 39 (2003) 107-114) synthetic 4-(4-hydroxybenzylidene Amino)aniline (4-(4-Hydroxybenzylideneimino)aniline). Under the protection of nitrogen, dissolve p-phenylenediamine and p-hydroxybenzaldehyde in equal molar ratio into DMF, add an appropriate amount of p-toluenesulfonic acid, and react at 80°C for 4 hours. An orange solid was obtained after precipitation. Filter, wash with methanol / water (50:50, v / v) mixture, and filter. Drying under reduced pressure, the melting point of the product is 241°C (DSC). 1 H NMR (DMSO-d 6 , δppm) 8: 45 (s, 1H, CH=N), 8.0-6.6 (m, 12H, aromatic), 4.25 (s, broad, 2H, NH 2 ).

[0032] (2) Synthesis of aldehyde-terminated compounds Bromine-terminated polyethylene glycol (BrCH 2 CH 2 (OCH 2 CH 2 ) 8 Br) (0.1mol), K 2 CO 3 (14.0g, 0.25mol), p-Hydroxybenzaldehyde (30.5g, 0.25mol) was dissolved in 250mL dry dimethyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com