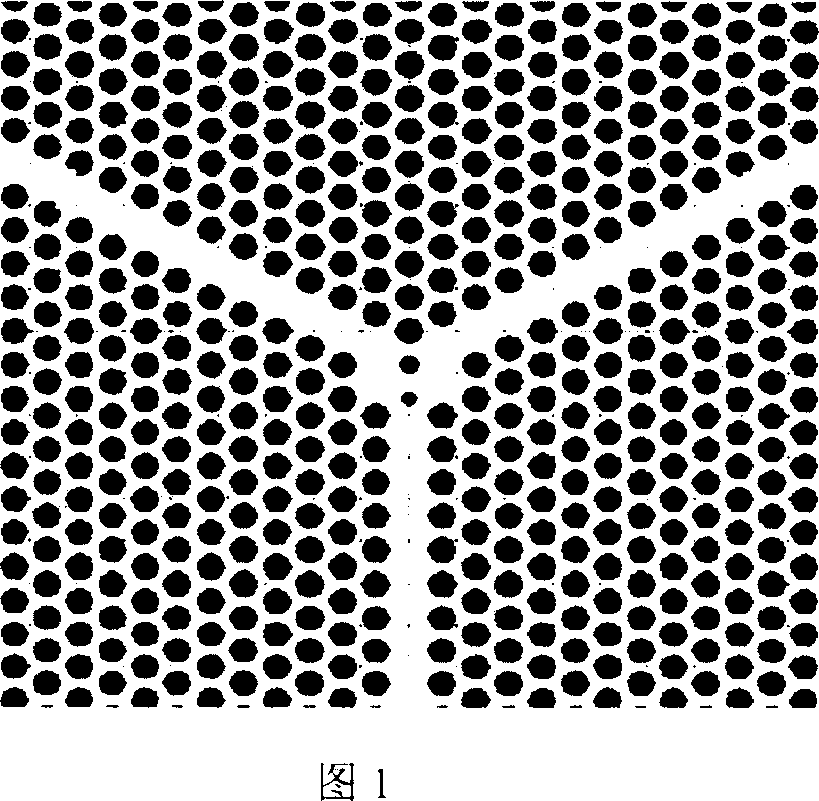

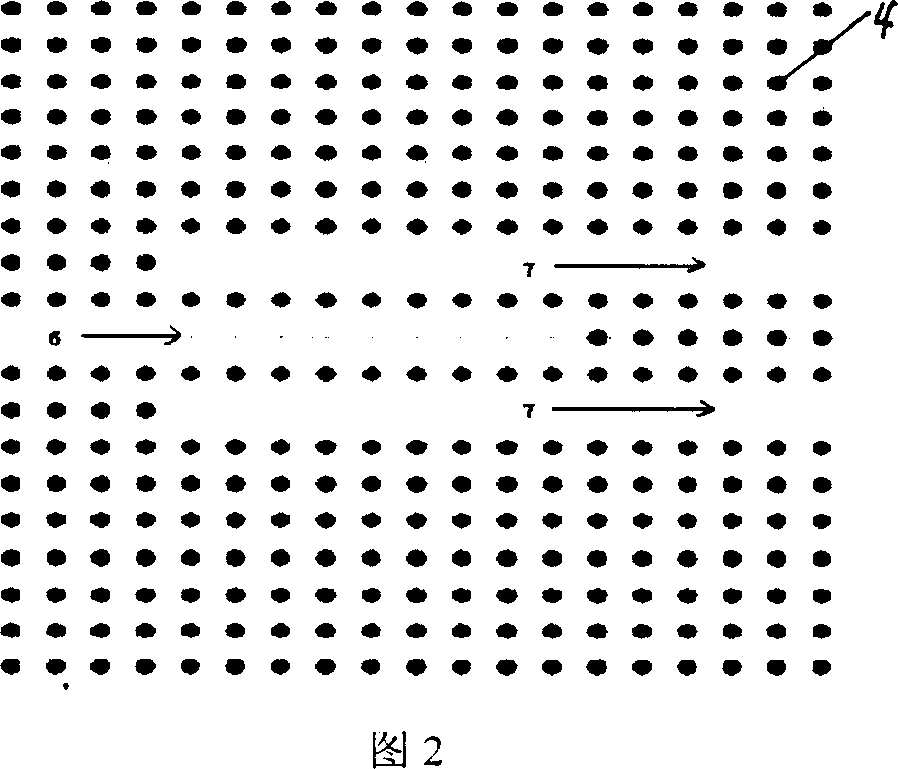

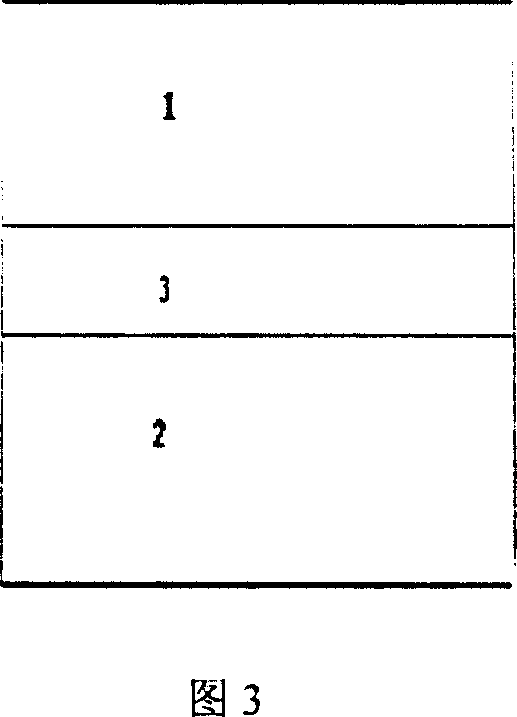

Photonic crystals splitter based on SOI and preparing method

A photonic crystal and beam splitter technology, applied in the direction of optical waveguide and light guide, can solve the problems of shortened device length, difficult manufacturing, large manufacturing tolerance, etc., and achieve the effect of reduced device size, wide available bandwidth range, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) First, immerse the SOI material in HF acid to remove surface oxides, shake and clean the chip with deionized water, heat it in acetone solution, let it cool naturally at room temperature after boiling, and then wash it with deionized water 30 times Above, then put it into absolute ethanol to repeat the heating, cooling and cleaning process; then clean it with an ultrasonic cleaner for 5 minutes, and finally blow dry the piece with nitrogen, and bake it in a 100°C oven for 3-4 minutes;

[0047] (2) Glue rejection: due to deep silicon etching, in order to obtain high-resolution and high-aspect-ratio graphics, a double-layer glue process is used: first, a coating with a thickness of about 500nm, a molecular weight of 950, and a concentration of 4% is applied on SOI The positive resist PMMA, the underlying photoresist PMMA is used as a mask for SOI patterning, and it is baked in an oven at 85°C for one hour to evaporate the solvent in PMMA and promote the adhesion of PMM...

Embodiment 2

[0062] Make a photonic crystal beam splitter based on SOI material of a utility model by the method for embodiment 1, its technology is the same as embodiment 1, only process condition has following difference:

[0063] (2) Glue rejection: first coat the positive glue PMMA with a thickness of about 600nm, a molecular weight of 950, and a concentration of 4% on the SOI, and bake it in an oven at 75°C for 2 hours after the glue is shaken; the glue is completely cured and then coated Negative resist HSQ about 70nm thick; bake at 80°C for 5 minutes;

[0064] (3) Electron beam exposure: Electron beam exposure technology is adopted, and the exposure conditions are: accelerating bias voltage 30Kv, aperture light beam 30μm, write field size 200μm 2 , exposure dose 250μC / cm -2 ;

[0065] (4) Development: first develop in MF322 developer for 2 minutes, then immerse in MF322:H2O=1:9 mixture for 12s, and finally wash in water for 25s;

[0066] (5) Reactive ion etching (RIE): with oxyge...

Embodiment 3

[0070] Make a photonic crystal beam splitter based on SOI material of a utility model by the method for embodiment 1 and example 2, its technology is the same as embodiment 1 and example 2, just process condition has following difference:

[0071] (3) Electron beam exposure: Electron beam exposure process is adopted, and the exposure conditions are: accelerating bias voltage 100Kv, aperture light beam 40μm, write field size 300μm 2 , exposure dose 800μC / cm -2 ;

[0072] (4) Development: first develop in MF322 developer for 50s, then immerse in MF322:H20=1:9 mixture for 16s, and finally wash in water for 20s;

[0073] (5) Reactive ion etching (RIE): with oxygen O 2 As a working gas, the RF power density is 0.10Wcm -2 , under the condition of pressure of 0.8Pa, the pattern is transferred from HSQ to the underlying adhesive PMMA;

[0074] (6) ICP etching: PMMA is used as an etching mask, and SOI material is etched by ICP. The etching conditions are as follows: cooling liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com