Apparatus for direct preparing silicon nitride by fluidized bed and process

A technology of fluidized bed and silicon nitride, which is applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve problems such as unexplained and complicated operation, and achieve improved nitriding efficiency, good heat and mass transfer, and gas solid reaction strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

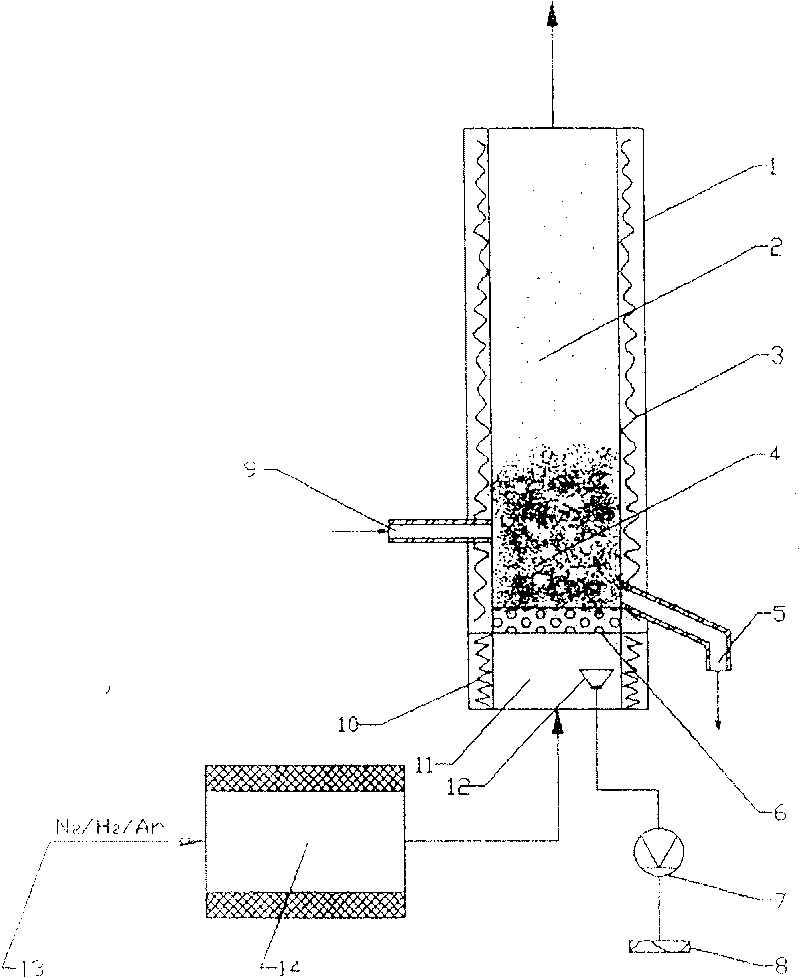

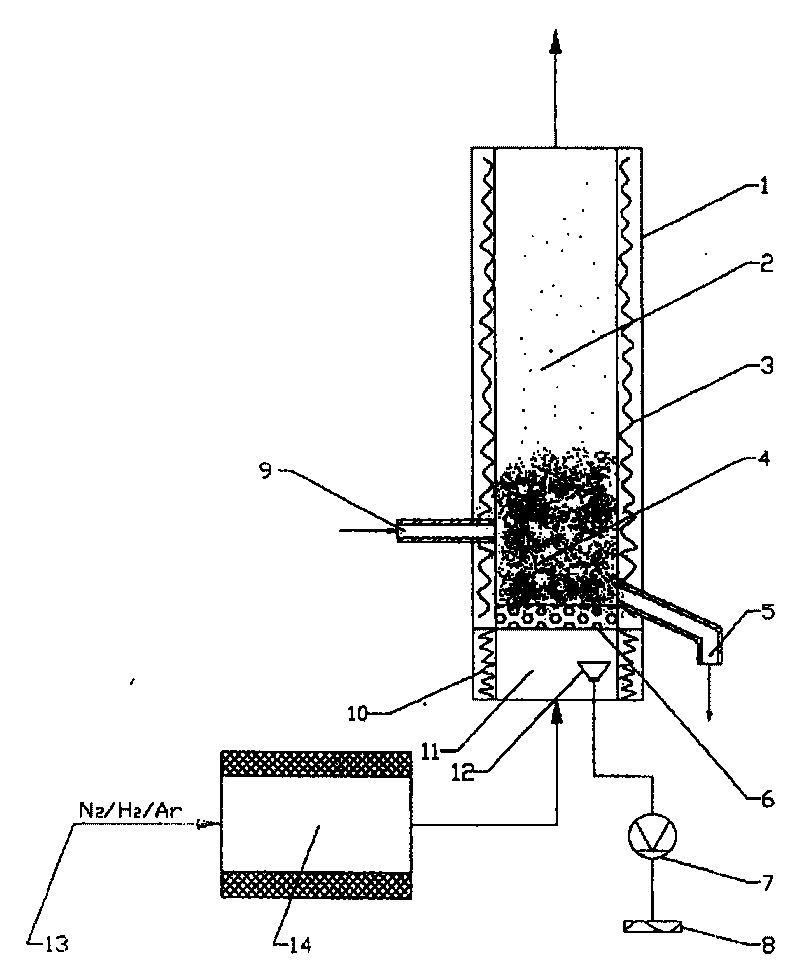

[0022] As shown in the figure, the device for directly producing silicon nitride in a fluidized bed has a fluidized bed body 1, and an air chamber 11, an air distribution plate 6, and a fluidized dense phase area 4 are arranged in sequence from the bottom to the top of the fluidized bed body. In the fluidized dilute phase zone 2, a heating device 3 is provided on the main side wall of the fluidized zone, an auxiliary heating device 10 is provided on the main side wall of the air chamber, and a feeding device 9 and an outlet are provided on the main side wall of the fluidized zone. The material device 5 is provided with a sounding device 12 in the air chamber. The sound signal of the sounding device 12 comes from the acoustic signal generator 8 and is amplified by the power amplifier 7. The bottom of the air chamber is connected with a preheating chamber 14.

[0023] The heating device is heated by electric heating or high-temperature flue gas with a temperature of 1000°C-1650°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com