Method and system for treating concentrated liquid from reverse osmosis of high concentration waste water

A technology of high-concentration wastewater and treatment methods, applied in the fields of osmosis/dialysis water/sewage treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc. problems, to achieve the effect of efficient treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

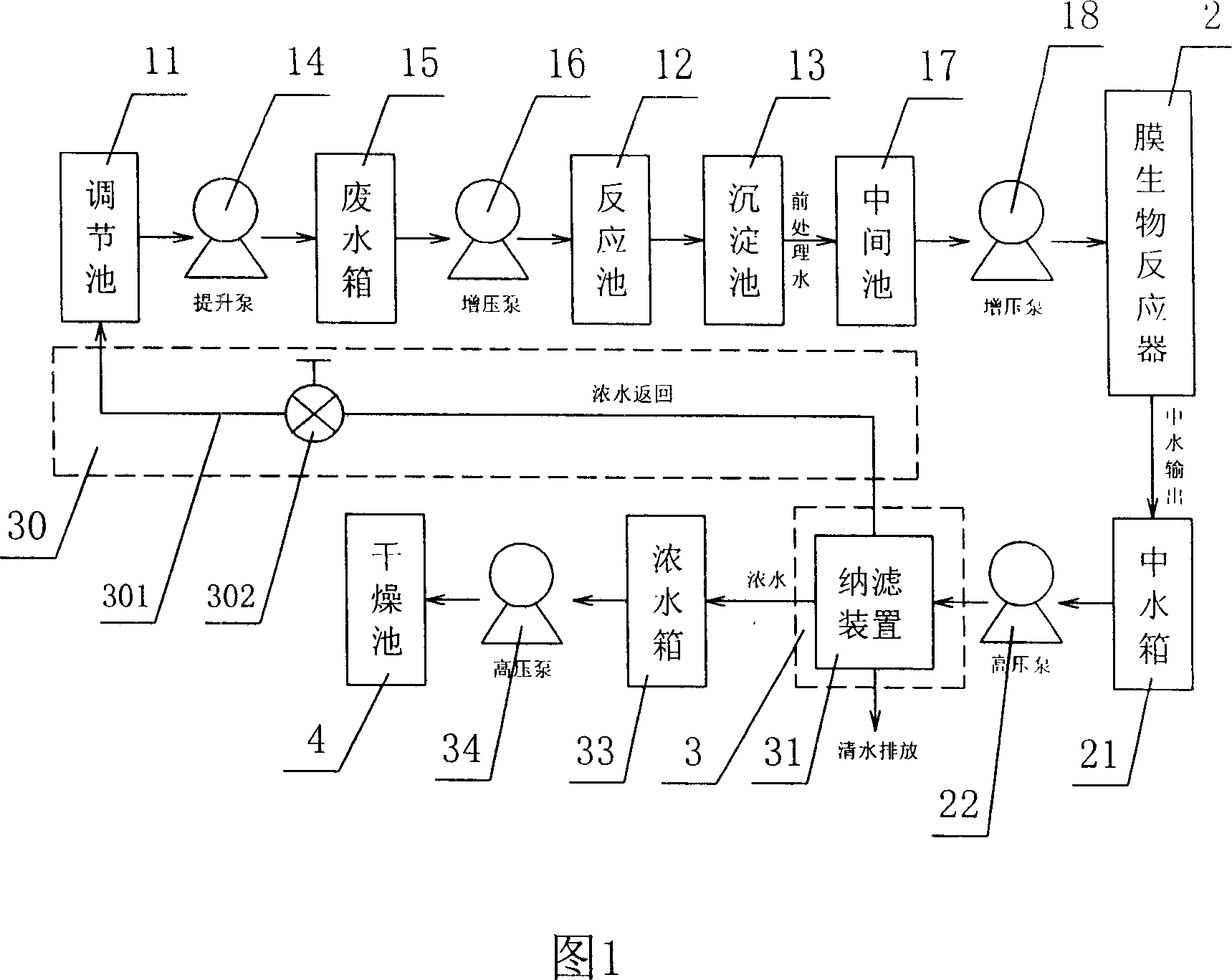

[0040] According to Fig. 1, the present invention includes at least the adjustment tank 11, the reaction tank 12, the sedimentation tank 13 and related pump equipment, the membrane bioreactor 2, the membrane treatment system 3 and the enhanced drying tank 4 that carry out the primary physical and chemical treatment of the landfill leachate. The pretreatment water produced by the primary physical and chemical treatment is input to the membrane bioreactor 2, and the membrane bioreactor 2 includes activated sludge method---aerobic tank and hollow fiber ultrafiltration membrane. In the present invention, the membrane bioreactor 2 Integrating activated sludge method and membrane separation, membrane separation is performed at the same time as biological treatment. After membrane bioreactor 2 performs biological treatment and membrane separation on pre-treated water, membrane bioreactor 2 outputs reclaimed water to membrane treatment system 3 , the membrane treatment system 3 perform...

Embodiment 2

[0063] As shown in FIG. 7 , the difference between this embodiment and Embodiment 1 is that in this embodiment, the membrane treatment system 3 adopts a reverse osmosis membrane device 32 to perform single-stage membrane treatment on reclaimed water.

[0064] The principles, structures, and methods of other parts are the same or similar to those described in Embodiment 1, and will not be repeated here.

[0065] In the present invention, a plurality of nanofiltration devices 31 or a plurality of reverse osmosis membrane devices 32 can be used to carry out multi-stage membrane treatment of reclaimed water, which can be implemented without creative work for those of ordinary skill in the art. I won't repeat them here.

Embodiment 3

[0067] As shown in Figure 8, the difference between this embodiment and Embodiment 1 is that in this embodiment, the membrane treatment system 3 uses a nanofiltration device 31 and a reverse osmosis membrane device 321, 322 to perform multi-stage membrane treatment on reclaimed water. The multi-stage membrane specifically includes three-stage membrane treatment, which is completed through nanofiltration device 31, concentrated water tank 33, high-pressure pump 34, primary reverse osmosis membrane device 321, concentrated water tank 35, high-pressure pump 36, and secondary reverse osmosis membrane device 321. grade film treatment.

[0068] The principles, structures, and methods of other parts are the same or similar to those described in Embodiment 1, and will not be repeated here.

[0069] Similarly, the use of the nanofiltration device 31 and the reverse osmosis membrane device 32 can complete the 2-stage and 3-stage membrane treatment, which can be implemented by those skil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com