Process of extracting luteolin-O-beta-D-glucoside from elsholtzia bodinieri

A technology of luteolin and glucoside, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of reducing atherosclerosis and cholesterol, achieve high extraction rate, simple extraction process, and easy preparation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

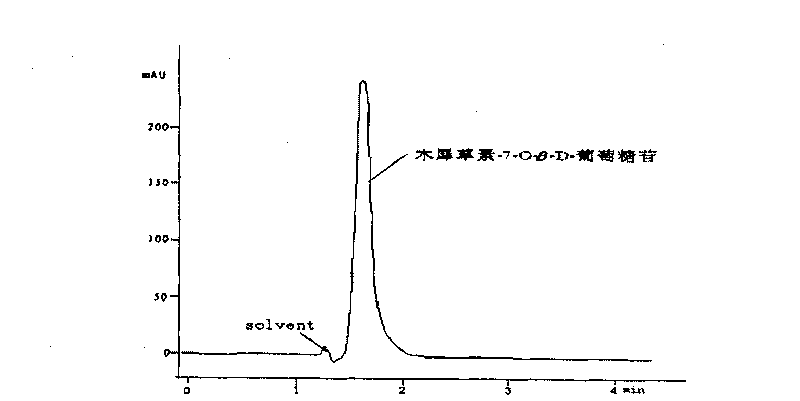

[0014] Example 1, Eastern perilla is collected from Honghe Prefecture, Yunnan Province. 500 g of the whole plant of Eastern perilla is crushed, and 4000 ml of ethanol-water is used as the extractant, and the extraction is refluxed, wherein the volume percentage of ethanol is 70%, and the extract is concentrated under reduced pressure After ethanol is gone, the concentrated solution of Dongbasil extract is obtained, which is extracted three times with ethyl acetate equal to the volume of the concentrated solution, and the aqueous phase extracted with ethyl acetate is concentrated under reduced pressure to remove residual ethyl acetate, and then freeze-dried to obtain Osmanthus osmanthus The crude product of luteolin-7-O-β-D-glucoside, the content determined by HPLC and UV is 80%, and the crude product is crystallized and recrystallized to obtain pure luteolin-7-O-β-D-glucoside Product, HPLC, UV assay content is 96%.

Embodiment 2

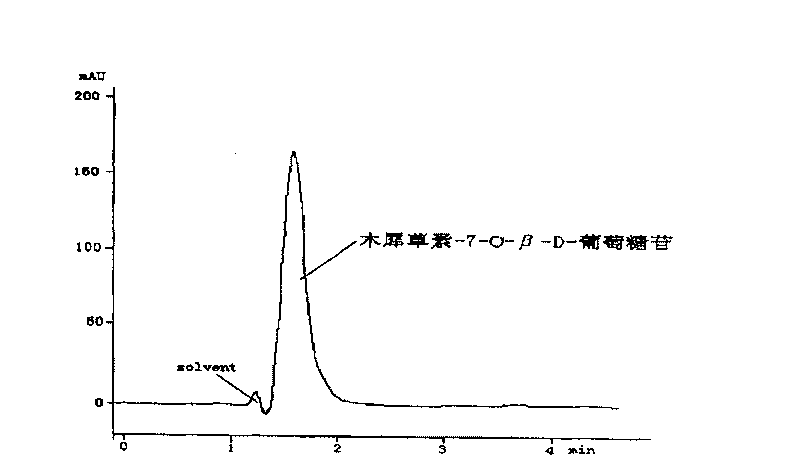

[0015] Example 2: Grind 500 g of the whole herb of Eastern Perilla, use 7000 ml of ethanol-water as the extractant, and extract under reflux, wherein the volume percentage of ethanol is 90%, and the extract is concentrated under reduced pressure until there is no ethanol to obtain concentrated Eastern Perilla Extraction, the Eastern perilla extract is made into an aqueous suspension, extracted three times with chloroform equal to the volume of the suspension, the aqueous phase after the chloroform extraction is then extracted with 1-pentanol, and the 1-pentanol extraction phase is concentrated under reduced pressure, Vacuum drying, then get crude luteolin-7-O-β-D-glucoside, HPLC, UV assay content is about 61%, crystallize and recrystallize the crude product, then get luteolin-7-O-β - The pure product of D-glucoside, the content determined by HPLC and UV is 98%.

Embodiment 3

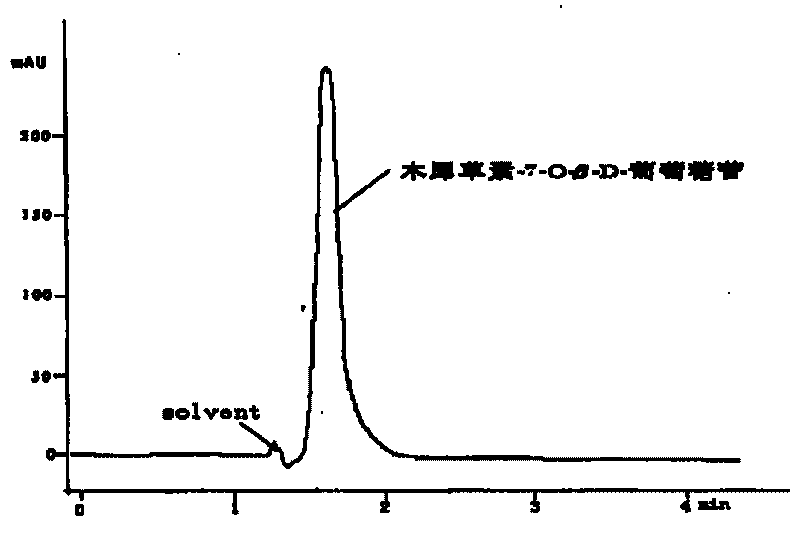

[0016] Example 3: Grind 500 g of the whole herb of Perilla basil, use 10,000 ml of acetone-water as the extractant, and extract under reflux, wherein the volume percentage of acetone is 60%, and the extract is concentrated under reduced pressure until there is no acetone, and then the extract of basil is obtained. Extract the concentrated solution with petroleum ether equal to the volume of the concentrated solution twice for degreasing, pass the water phase through the macroporous adsorption resin, wash with water until the effluent is colorless, use 95% ethanol as the eluent for elution, and concentrate the eluent under reduced pressure Afterwards, freeze-dry to obtain luteolin-7-O-β-D-glucoside fine product, and the HPLC and UV determination content is about 90%; carry out crystallization and recrystallization to crude product and fine product, then obtain luteolin-7 -O-β-D-glucoside pure product, HPLC, UV assay content is 99%. Among them, the macroporous adsorption resin i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com