Ring-shaped magnetic multi-layer film and method for making same and use

A multi-layer film and magnetic technology, applied in the application of magnetic film to substrate, magnetic layer, multi-layer film with spin exchange coupling, etc., can solve the problem of complex structure design and preparation of memory cells, increasing free layer inversion issues such as field and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

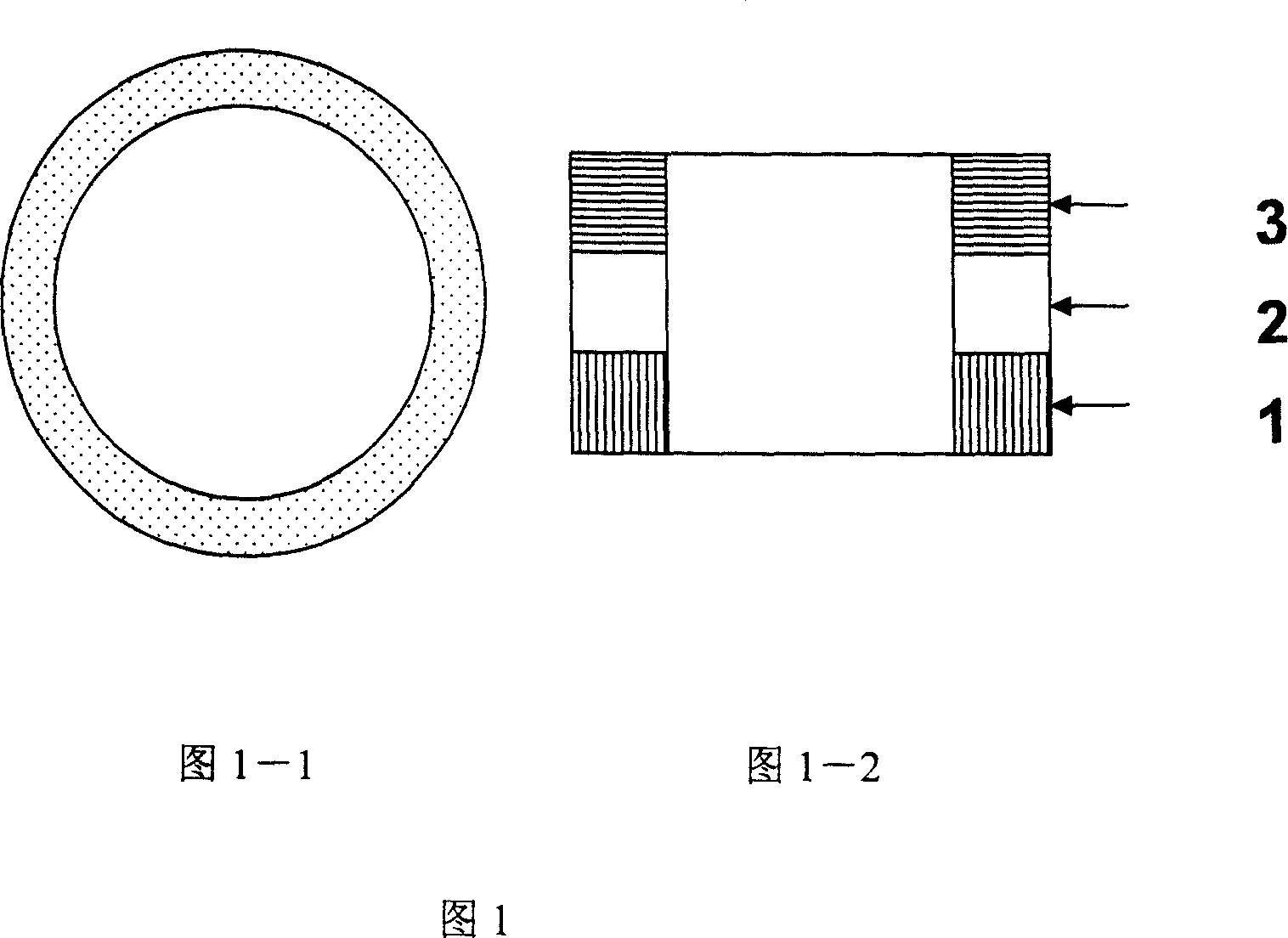

[0053] Example 1. Preparation of non-pinning annular magnetic multilayer film by micromachining method

[0054] Using high-vacuum magnetron sputtering equipment in the 1mm thick SiO cleaned by conventional methods 2 On the Si substrate, the lower buffer conductive layer Au with a thickness of 2nm, the hard magnetic layer (HFM) Co with a thickness of 3nm, the intermediate layer (I1) Cu with a thickness of 1nm, and the soft magnetic layer (SFM) with a thickness of 1nm were deposited sequentially. Co and a cap layer Ru with a thickness of 4 nm. The growth conditions of the above-mentioned magnetic multilayer film: prepared vacuum: 5×10 -7 Pa; high-purity argon gas pressure for sputtering: 0.07 Pa; sputtering power: 120 watts; sample holder rotation rate: 20rmp; growth temperature: room temperature; Rate; when depositing hard magnetic layer and soft magnetic layer, apply a 50Oe plane induced magnetic field. The deposited magnetic multilayer film adopts the micro-processing tech...

Embodiment 2

[0055] Example 2. Preparation of non-pinning annular magnetic multilayer film by using insulator nanoparticle mask method

[0056] Using high-vacuum magnetron sputtering equipment on 0.3mm thick Si / SiO cleaned by conventional methods 2 A lower buffer conductive layer of Au with a thickness of 2nm is sequentially deposited on the substrate, and a layer of SiO with a diameter of 100nm is dispersed on the lower buffer conductive layer. 2 particles, and then use high-vacuum magnetron sputtering equipment to sequentially grow a hard magnetic layer (HFM) Co with a thickness of 20nm 75 Fe 25 , an intermediate layer (I1)Cr with a thickness of 10nm, a soft magnetic layer (SFM)Co with a thickness of 10nm 75 Fe 25 and a capping layer Ta with a thickness of 10 nm. The growth conditions of the above-mentioned magnetic multilayer film: prepared vacuum: 5×10 -7 Pa; high-purity argon gas pressure for sputtering: 0.07 Pa; sputtering power: 120 watts; sample holder rotation rate: 20rmp; gr...

Embodiment 3

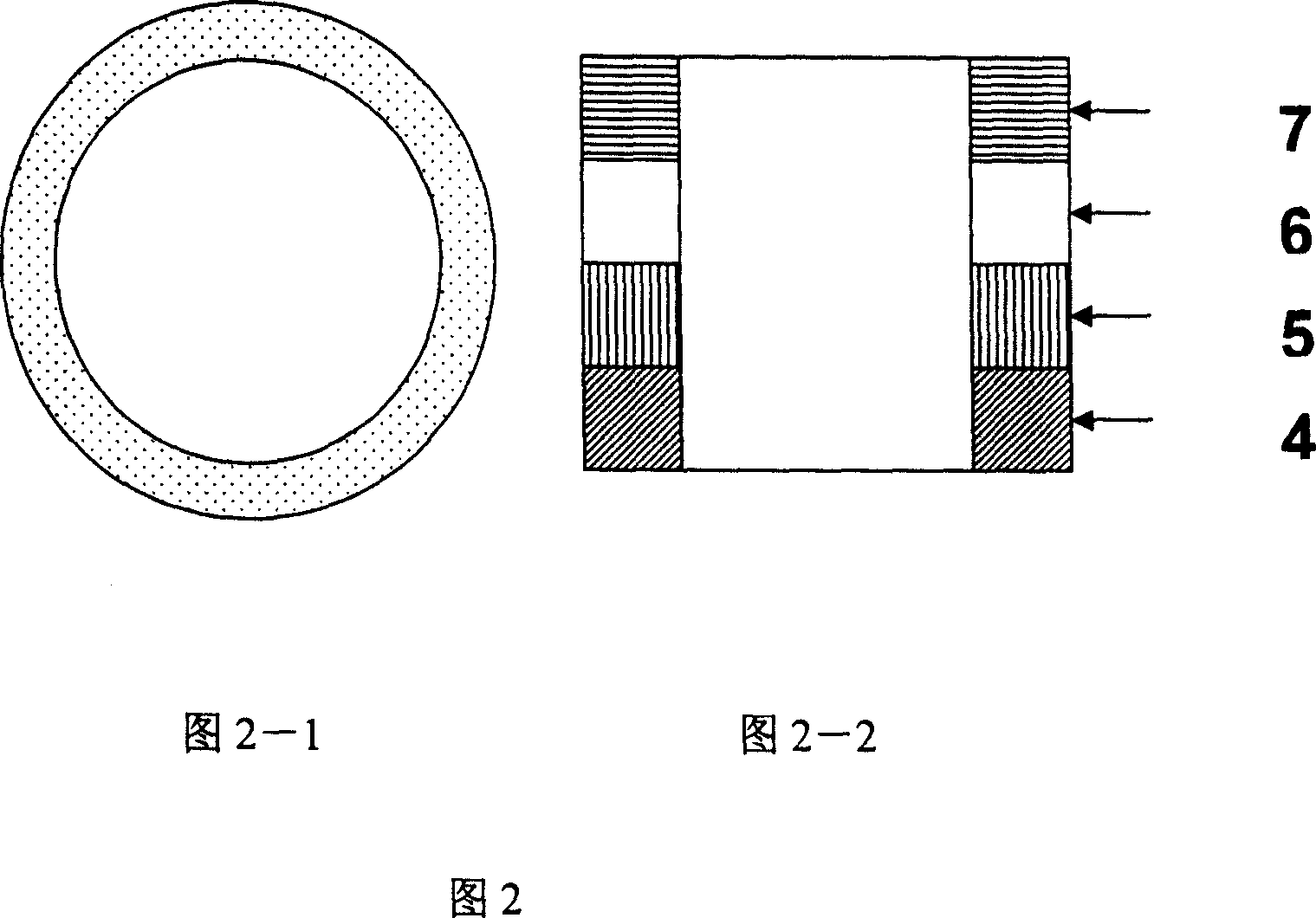

[0057] Example 3. Preparation of pinned annular magnetic multilayer film by micromachining method

[0058] Using high vacuum magnetron sputtering equipment to clean 0.8mm thick Si / SiO by conventional methods 2 The lower buffer conductive layer Au with a thickness of 2 nm, the antiferromagnetic pinning layer (AFM) IrMn with a thickness of 10 nm, and the pinned magnetic layer (FM1) Co with a thickness of 3 nm were sequentially deposited on the substrate. 90 Fe 10 ; then deposit 1nm of Al, the insulating layer formed through plasma oxidation for 50 seconds as the intermediate layer (I2); on this intermediate layer, the free soft magnetic layer (FM2) Co with a thickness of 3nm is deposited successively 90 Fe 10 and a capping layer of Au with a thickness of 2 nm. The growth conditions of the above-mentioned magnetic multilayer film: prepared vacuum: 5×10 -7 Pa; high-purity argon gas pressure for sputtering: 0.07 Pa; sputtering power: 120 watts; sample holder rotation rate: 20rm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com