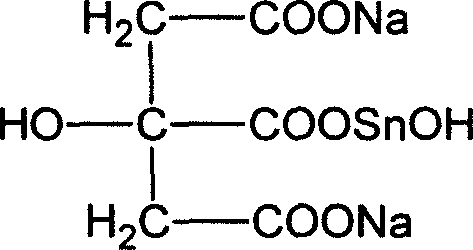

Distannous citrate preparation method

A technology of disodium stannous citrate and trisodium citrate, which is applied in the field of preparation of food additives, can solve problems such as difficult crystallization of disodium stannous citrate, difficulty in meeting requirements for water-insoluble substances, and high energy consumption for water evaporation. Achieve beautiful appearance, reduce energy consumption, and avoid production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

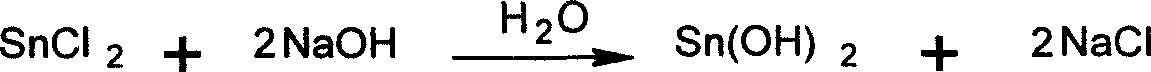

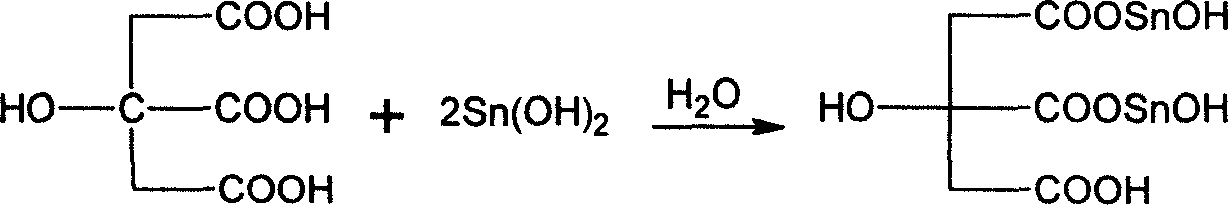

Embodiment 1

[0036] Dissolve 160 grams of sodium hydroxide in 500 mL of pure water under stirring, filter and set aside. Weigh 450 grams of stannous chloride and dissolve it in 250 grams of hot water at 80°C, add 0.5 grams of metal tin powder, keep warm and stir for half an hour, then heat filter. Add the clarified sodium hydroxide solution into the stannous chloride filtrate under stirring at 50°C until the pH value of the system is 9 to obtain a stannous hydroxide suspension. Add a solution of 210 grams of citric acid dissolved in 150 grams of pure water at 50°C, continue to stir and react for 1 hour after the addition, cool to room temperature, centrifugally filter and wash to remove sodium chloride, then centrifuge and dry the water as much as possible to obtain Lemon Distannous acid intermediate. Add wet stannous citrate into 1000mL of 95% ethanol, stir evenly, add 210g of citric acid at 50°C, continue stirring for 1 hour, then add 160g of sodium hydroxide dissolved in 1500mL of 95% ...

Embodiment 2

[0044] Dissolve 240 grams of sodium hydroxide in 750 mL of pure water under stirring, filter and set aside. Weigh 677 grams of stannous chloride and dissolve it in 380 grams of hot water at 80° C., add 0.8 grams of metal tin powder, keep stirring for half an hour, and then heat filter. Add the clarified sodium hydroxide solution into the stannous chloride filtrate under stirring at 50°C until the pH value of the system is 9 to obtain a stannous hydroxide suspension. Add a solution of 210 grams of citric acid dissolved in 150 grams of pure water at 50°C. After the addition, continue to stir and react for 1 hour, cool to room temperature, and centrifugally filter and wash to remove sodium chloride. The particle size of the stannous suspension is extremely small, and part of the unconverted tin hydroxide is also filtered out during the filtration, and the obtained solid is vacuum-dried at 55° C. to obtain 570-580 grams of a white solid product, which is crushed for later use. An...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com