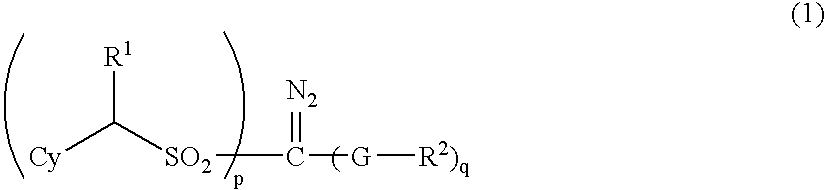

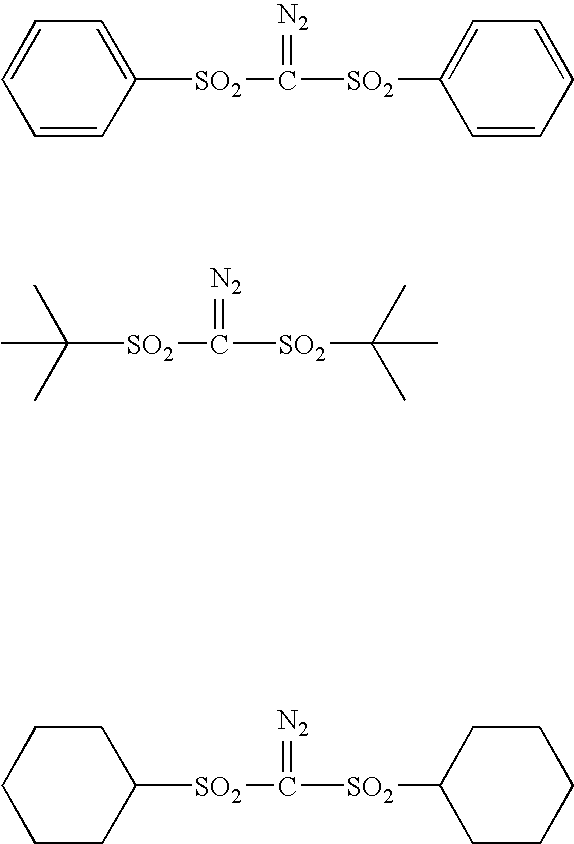

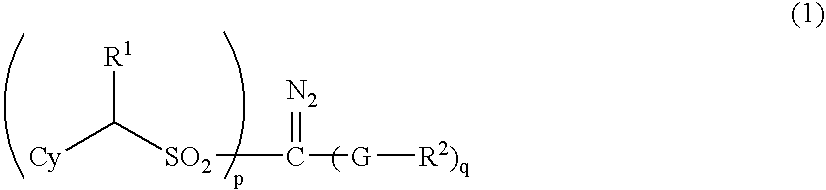

Novel sulfonyldiazomethane compounds, photoacid generator, resist materials and patterning process using the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

synthesis example 1

Synthesis of ((4-(1,3-dioxolan-2-yl)-1-hydroxycyclohexyl)methyl)trimethylsilane

A Grignard reagent was prepared in a conventional manner by using 44.6 g (0.36 mole) of (chloromethyl)trimethylsilane, 8.8 g (0.36 mole) of metal magnesium and 194 g of diethyl ether. To the resulting Gignard reagent was added 50.9 g (0.33 mole) of 1,4-cyclohexanedione monoketal over an ice bath at a temperature below 20° C. After stirring for 2 hours at 40° C., 125 g of water was added to the resulting mixture over an ice bath. The supernatant thus separated was collected, and washed with 200 g of saturated sodium chloride water. The solvent was removed under reduced pressure, whereby 77.6 g of ((4-(1,3-dioxolan-2-yl)-1-hydroxycyclohexyl)methyl)trimethylsilane was obtained.

synthesis example 2

Synthesis of 1-(1,3-dioxolan-2-yl)-4-methylenecyclohexane

After 15.7 g (0.39 mole) of sodium hydride was washed with n-hexane, it was suspended in 199 g of tetrahydrofuran. A solution obtained by dissolving the above hydroxysilane in 112 g of tetrahydrofuran was added dropwise, followed by aging for 41 hours under heating and reflux. After 140 g of water was added to terminate the reaction, the organic phase was obtained by separation. The resulting organic phase was washed with 60 g of saturated sodium chloride water. The solvent was then removed under reduced pressure, whereby the target 1-(1,3-dioxolan-2-yl)-4-methylenecyclohexane was obtained (two step yield: 77%). Gas chromatography revealed that its purity was 83%.

synthesis example 3

Synthesis of S-((4-(1,3-dioxolan-2-ylcyclohexyl)methyl)thioacetate

In 188 g of tetrahydrofuran was dissolved 46.8 g (0.25 mole) of the above methylenecyclohexane. Thioacetic acid (22.0 ml, 0.31 mole) was added dropwise to the resulting solution at a speed slow enough not to increase the internal temperature, followed by aging for 1 hour. After further addition of 3.5 ml (0.05 mole) of thioacetic acid and aging for 30 minutes, 200 g of a saturated aqueous solution of sodium bicarbonate was added to terminate the reaction. The organic phase obtained by separation of the reaction mixture was washed with 50 g of saturated sodium chloride water. The solvent was then removed under reduced pressure, whereby 76.7 g of the target S-((4-(1,3-dioxolan-2-ylcyclohexyl)methyl)thioacetate was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nanoscale particle size | aaaaa | aaaaa |

| Solubility (mass) | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com