Hydrogen production method, hydrogen production apparatus, hydrogen supply facilities, nd method for generating electric power

a technology of hydrogen production apparatus and hydrogen supply, which is applied in the direction of gas dust removal, machine/engine, combustible gas production, etc., can solve the problems of increasing investment cost, generating carbon dioxide, and consuming fuel inevitably, so as to reduce running cost and facility cost , the effect of low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

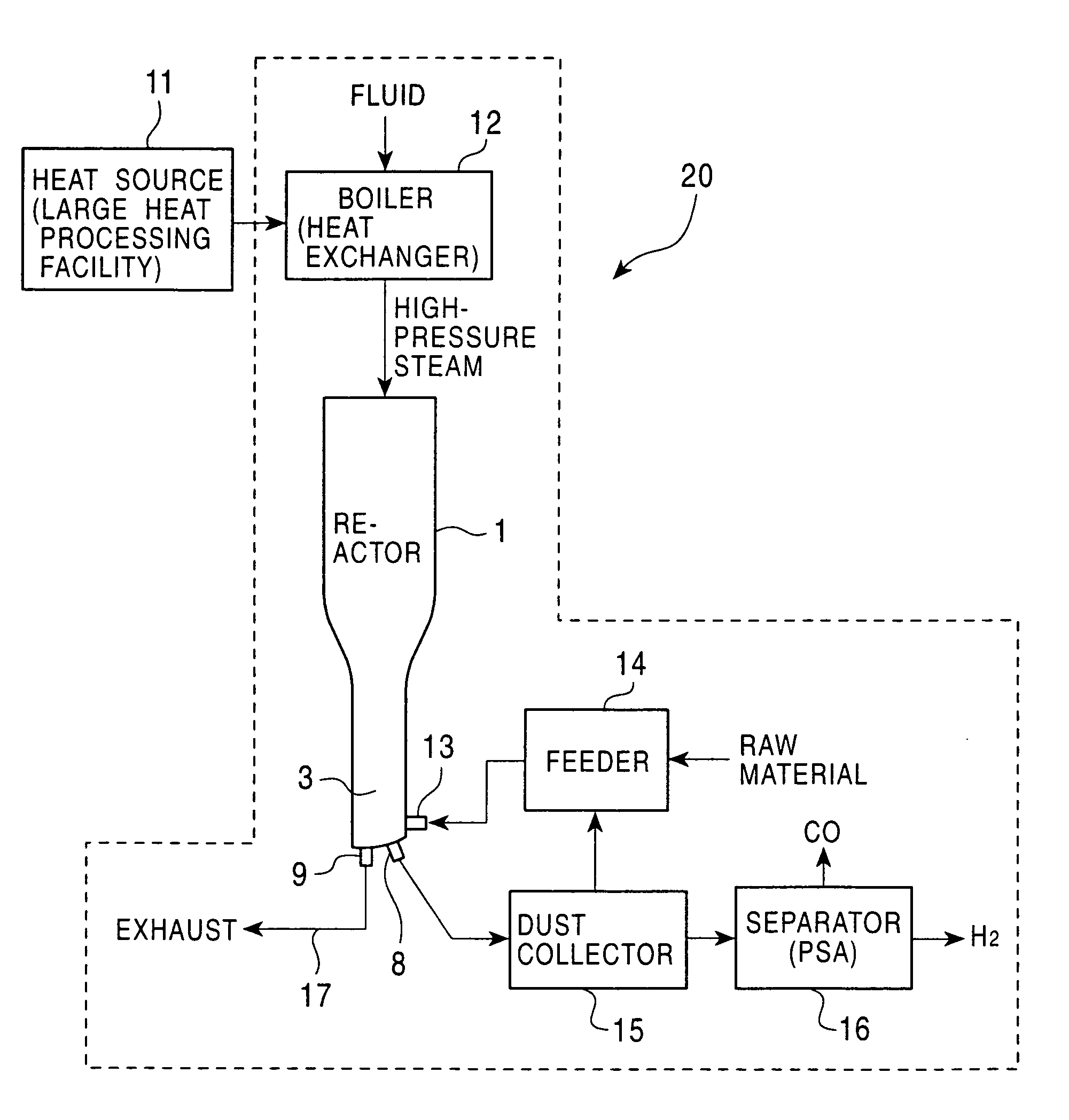

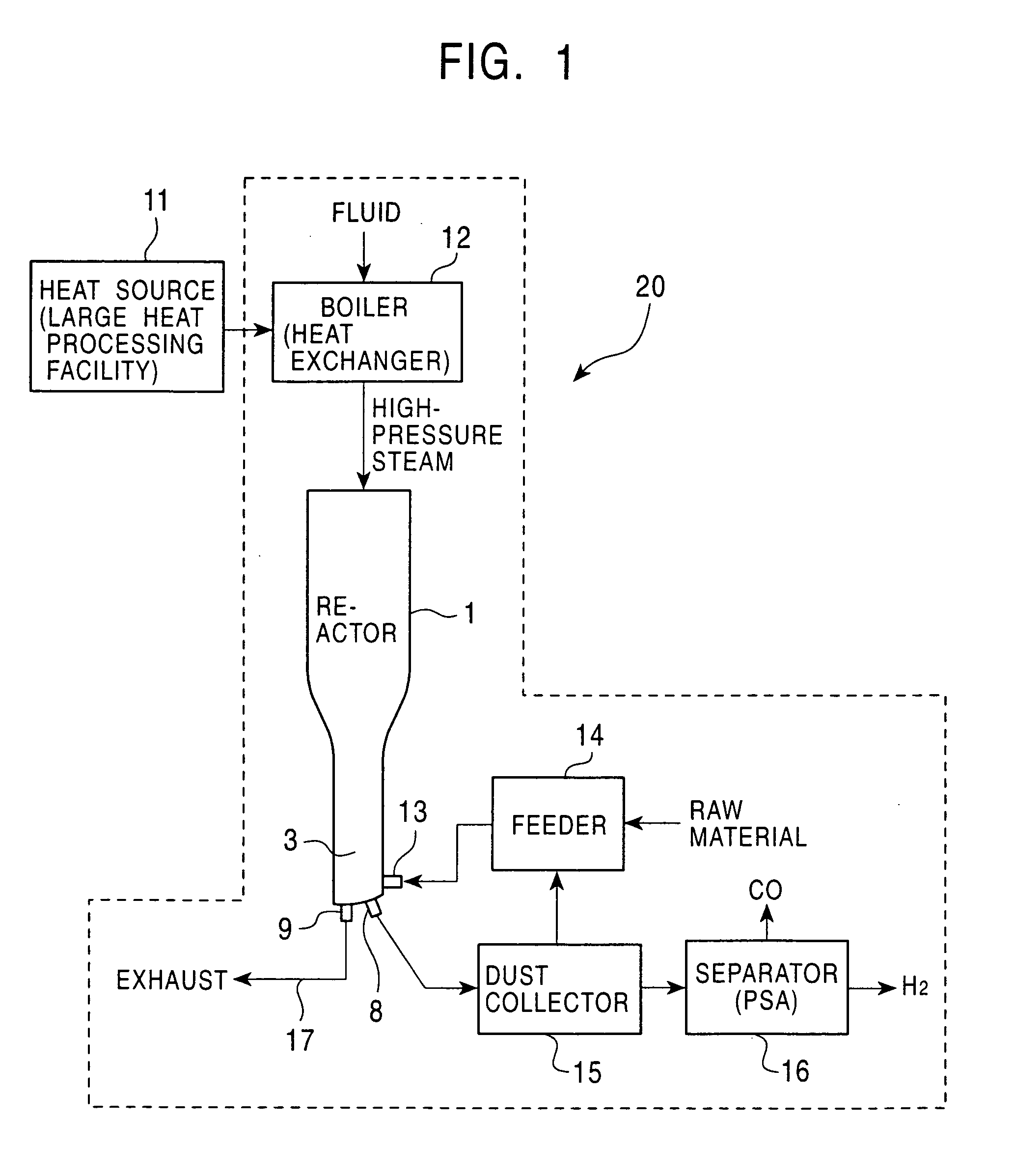

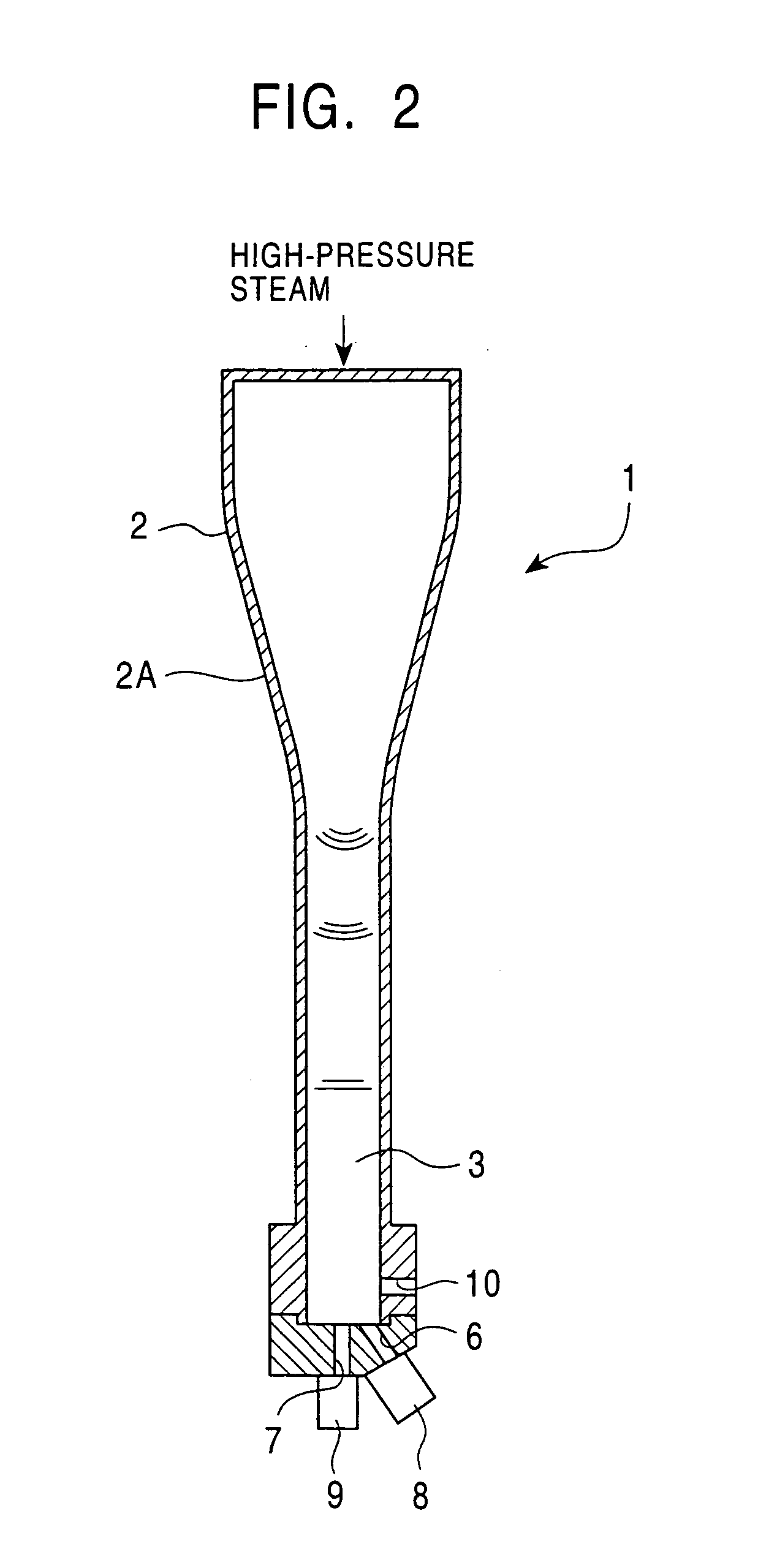

[0113]FIG. 1 is a structural block diagram of an apparatus for producing hydrogen according to Embodiment 1 of the present invention; and FIG. 2 is a sectional view of a reactor of the hydrogen production apparatus. In the figures, reference numeral 1 designates a reactor of a hydrogen production apparatus 20 conducting a reaction in which reactive particles containing hydrocarbon or carbon react with steam at a high temperature to produce hydrogen. The reactor includes a converging tube 2 having a converging portion 2A with a larger diameter at the upper end and a smaller diameter at the lower end and the cross section of the converging tube 2 thus decreases gradually from the upper end to the lower end. A space at the downstream side of the converging tube 2 defines a compression chamber 3 serving as a reaction chamber. High-pressure steam is instantaneously released to the converging tube 2 to generate shock waves, and the shock waves are converged in the converging portion 2A to...

embodiment 2

[0134]FIG. 4 is a structural block diagram of a hydrogen production apparatus according to Embodiment 2 of the present invention. In Embodiment 2, the boiler 12 being a heat exchanger of the hydrogen production apparatus 20 of Embodiment 1, which recovers the waste heat of exhaust gas from the heat source 11 and which heats a fluid (for example, water) to generate high-pressure steam by heat exchange, is replaced with a heater 12A which recovers the waste heat of exhaust gas from the heat source 11 and which heats a low-boiling-point fluid to generate high-pressure gas by heat exchange.

[0135] The low-boiling-point fluid has a boiling point lower than that of water, and may be LNG, LPG, liquefied carbon dioxide, ammonia, DME (dimethyl ether), an alcohol, or an ether. The low-boiling-point fluid itself may serve as a raw material of the reaction (hydrogen production) in some cases.

[0136] This structure provides substantially the same effects and advantages as Embodiment 1, and allow...

embodiment 3

[0137] In Embodiment 3 of the present invention, the hydrogen production apparatus 20 of Embodiment 1 is installed in a predetermined site to constitute a hydrogen supply plant, and is used as, for example, a hydrogen supply source for fuel-cell vehicles.

[0138] In the hydrogen supply plant having such a structure, when a fuel-cell vehicle comes in for feeding hydrogen, the hydrogen production apparatus 20 immediately starts operating to produce hydrogen and supply it into the tank of the vehicle. On completing hydrogen supply, the operation of the hydrogen production apparatus 20 is suspended. When another vehicle comes in, the hydrogen production apparatus 20 starts operation to supply hydrogen again as above.

[0139] Since the hydrogen production apparatus 20 is installed in a predetermined site to constitute a hydrogen supply plant, hydrogen is supplied to fill the object easily and immediately according to a demand for hydrogen, without providing an expensive hydrogen storage fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com