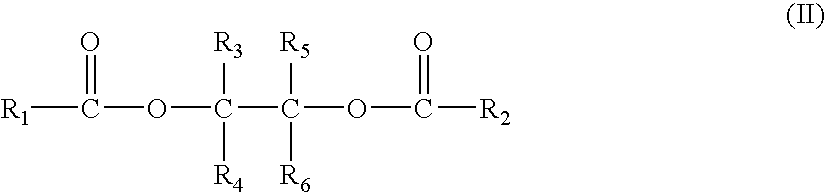

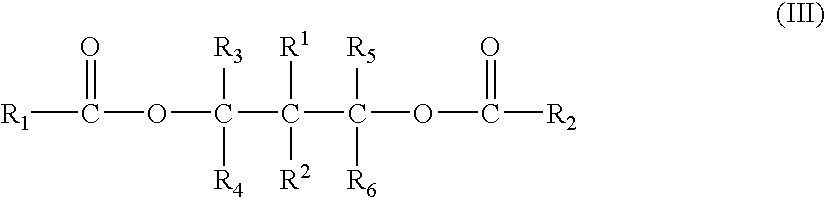

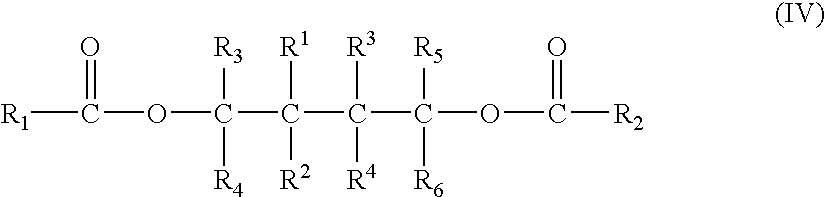

Polyol ester compounds useful in preparation of a catalyst for olefins polymerization, process for preparing the same and use thereof

a technology of polyol ester and polymerization catalyst, which is applied in the field of compounds, can solve the problems of narrow distribution of the molecular weight lower isotacticity of the polymer obtained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

Synthesis of 1,2-ethylene-glycol Dibenzoate

[0132] To 2.8 g (0.05 mol) 1,2-ethylene-glycol was added 50 ml tetrahydrofuran, then added 12.1 ml (0.15 mol) pyridine with stirring. To the resulting homogeneous mixture was slowly added 14.5 ml (0.125 mol) benzoyl chloride, and the mixture was stirred for 1 hour at room temperature, then heated refluxing for 4 hours. Upon completing the reaction, 70 ml water was added to dissolve the resulting salt. The mixture was extracted with toluene. Organic phase was separated, washed with saturated saline for two times, dried over anhydrous sodium sulfate. The solvent was removed to give a white solid. Recrystallization from ethyl acetate gave target product as a white crystal, and the yield was 92%. m.p. 69-70° C.

[0133]1HNMR δ (ppm):4.67 (s, 4H, CH2), 7.42-8.07 (m, 10H, ArH).

example 2

Synthesis of 1,2-butandiol Dibenzoate

[0134] To the reactor were added 1,2-butandiol (2.5 g), benzoyl chloride (7.8 g), pyridine (8.8 g) and tetrahydrofuran (70 ml). The reactants was mixed and heated refluxing for 4 hours, then cooled to room temperature. Water was added to the reaction system until the inorganic phase was transparent. Organic phase was separated. Inorganic phase was extracted with ethyl ether and then the organic phase was combined. The combined organic phase was washed with water, dried over anhydrous sodium sulfate. After concentrated, 3.95 g product was separated. 1H-NMR: δ (ppm) 1.0-1.1 (3H), 1.7-1.9 (2H), 4.4-4.6 (2H), 5.4-5.5 (1H) and 7.4-8.2 (10H).

example 3

Synthesis of 2,3-butandiol Dibenzoate

[0135] Synthesis procedure was similar to that described in Example 2, and 4.4 g of product was obtained from 2,3-butandiol. 1H-NMR: δ (ppm) 1.4-1.6 (6H), 5.3-5.5 (2H), 7.4-8.2 (10H).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com