Resin composition of good long-run workability comprising ethylene-vinyl alcohol copolymer

a technology of ethylenevinyl alcohol and composition, which is applied in the direction of synthetic resin layered products, layered products, chemistry apparatus and processes, etc., can solve the problems of not meeting the requirements of known moldings and no one can find out a satisfactory evoh composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1-1

[0202] A 45% solution in methanol of ethylene-vinyl acetate copolymer having an ethylene content of 38 mol % was put into a reactor for saponification, to which was added a solution of sodium hydroxide in methanol (80 g / liter), the amount of sodium hydroxide added being 0.4 equivalents to the vinyl acetate moiety of the copolymer. Then, methanol was added thereto to produce a solution having a copolymer concentration of 20%. This was heated up to 60° C. and reacted for about 4 hours with nitrogen gas being introduced into the reactor. After 4 hours, this was neutralized with acetic acid to stop the reaction. This was extruded out into water through a die having a circular opening, solidified therein and cut into pellets each having a diameter of about 3 mm and a length of about 5 mm. The resulting pellets were dewatered in a centrifuge. A large amount of water was added thereto, and the pellets were again dewatered. This operation was repeated.

[0203] 100 parts by weight of the wet ...

examples 1-2 to 1-6

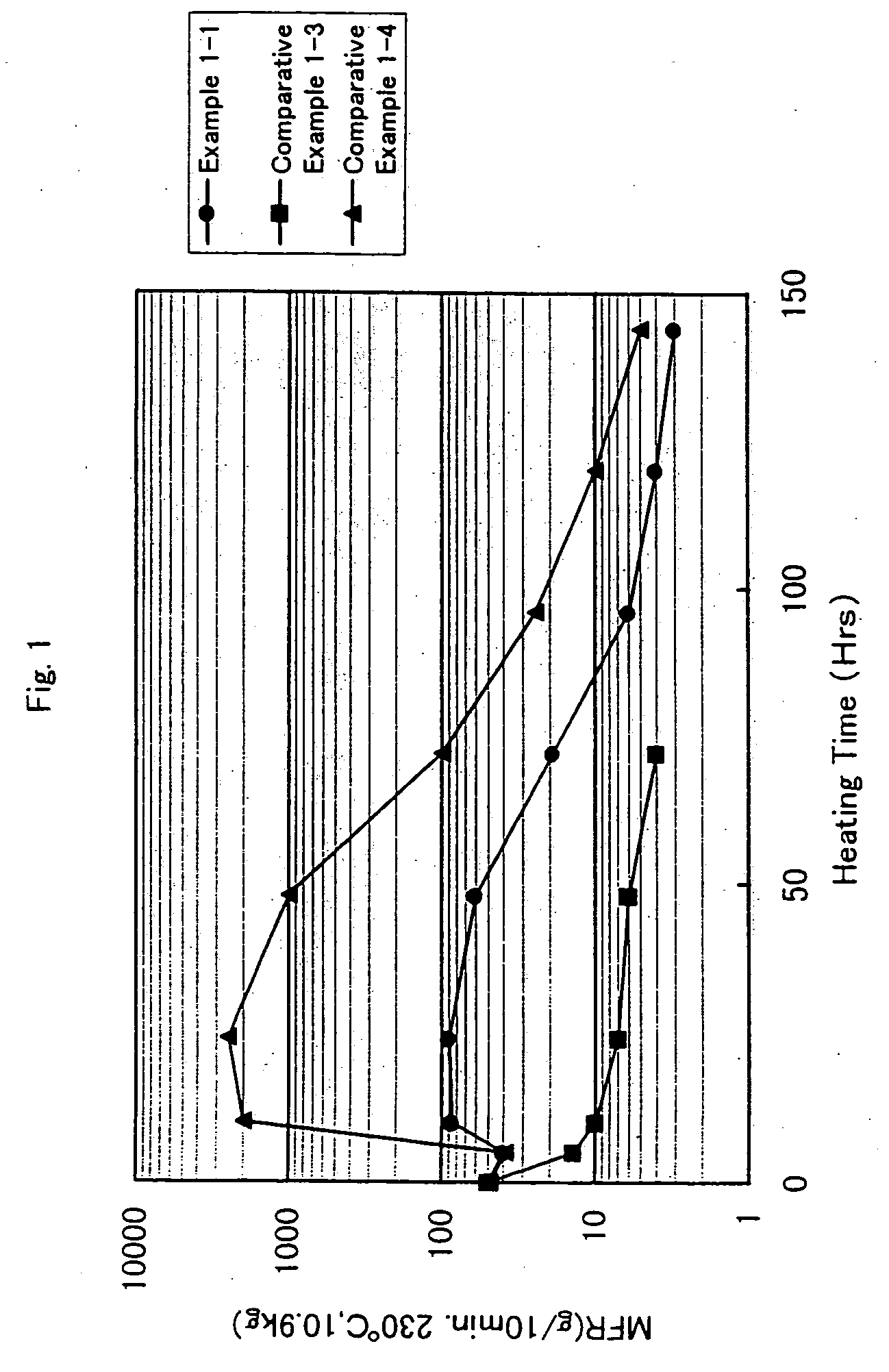

, Comparative Examples 1-1 to 1-4

[0210] Dry pellets were prepared in the same manner as in Example 1-1. In this, however, EVOH having an intrinsic viscosity as in Table 2 was used. After having been saponified, washed and dewatered, pellets of EVOH having an ethylene content of 38 mol % and a degree of saponification of 99.4% were blended with or not blended with the lubricant, and then dipped in different processing solutions as in Table 1. The dry pellets were formed into films and tested. The test data are in Table 3.

TABLE 1Composition of Processing SolutionCarboxylicAlkaliAlkaline EarthPhosphateBoronAcidMetal SaltMetal SaltCompoundCompoundAmountAmountAmountAmountAmountType(g / L)Type(g / L)Type(g / L)Type(g / L)Type(g / L)Example 1-1lactic acid0.08sodium lactate0.8magnesium0.31KH2PO40.17H3BO30.32lactateExample 1-2lactic acid0.08sodium lactate0.8calcium lactate0.45KH2PO40.17H3BO30.32Example 1-3lactic acid0.08sodium lactate0.8magnesium0.31KH2PO40.17—lactateExample 1-4lactic acid0.08sodium...

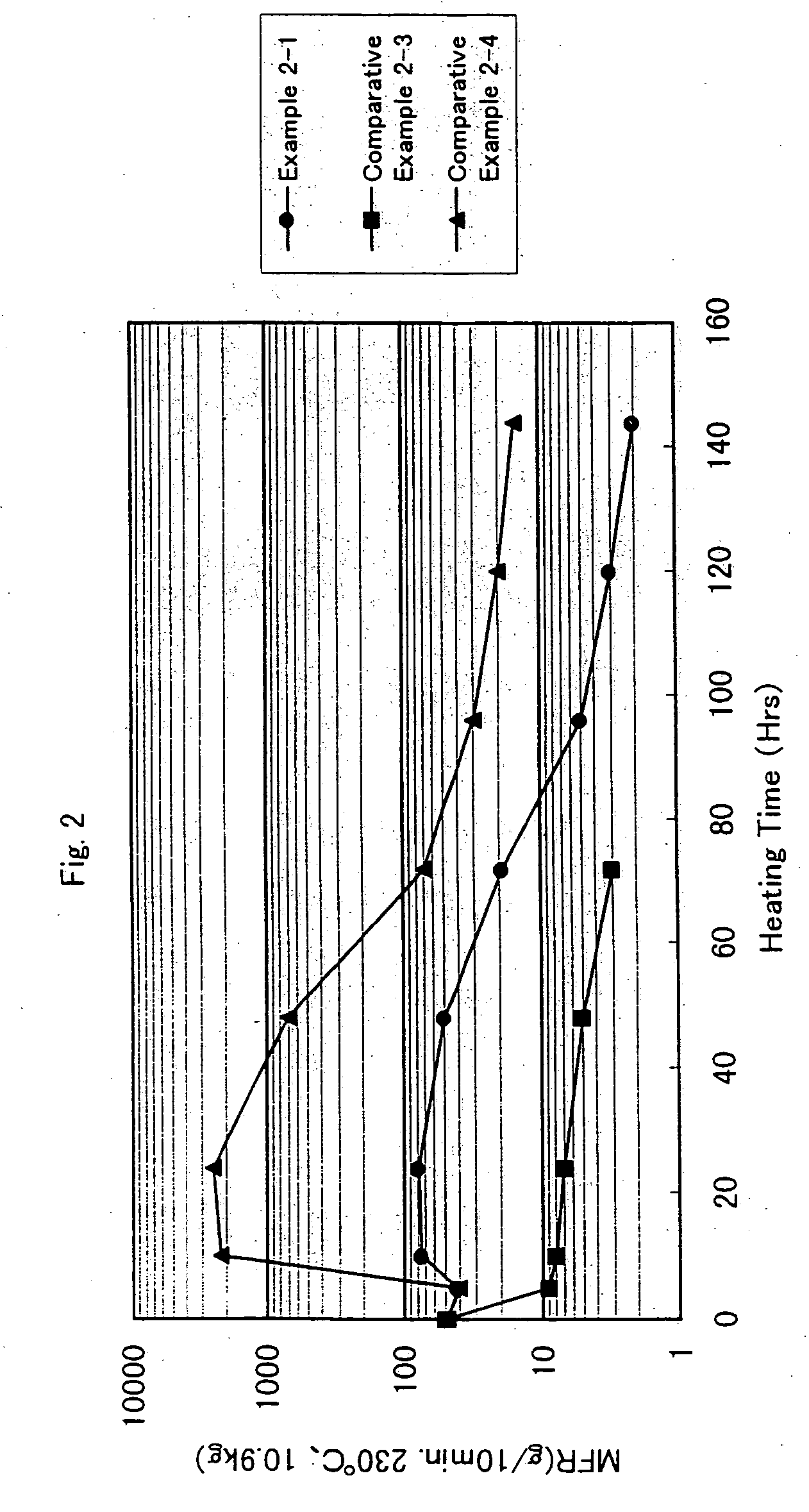

example 2-1

[0213] A 45% solution in methanol of ethylene-vinyl acetate copolymer having an ethylene content of 38mol % was put into a reactor for saponification, to which was added a solution of sodium hydroxide in methanol (80 g / liter), the amount of sodium hydroxide added being 0.4 equivalents to the vinyl acetate moiety of the copolymer. Then, methanol was added thereto to produce a solution having a copolymer concentration of 20%. This was heated up to 60° C. and reacted for about 4 hours with nitrogen gas being introduced into the reactor. After 4 hours, this was neutralized with acetic acid to stop the reaction. This was extruded out into water through a die having a circular opening, solidified therein and cut into pellets each having a diameter of about 3 mm and a length of about 5 mm. The resulting pellets were dewatered in a centrifuge. A large amount of water was added thereto, and the pellets were again dewatered. This operation was repeated.

[0214] 100 parts by weight of the wet E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com