Lidstock material having improved sealability and peelability to wide classes of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

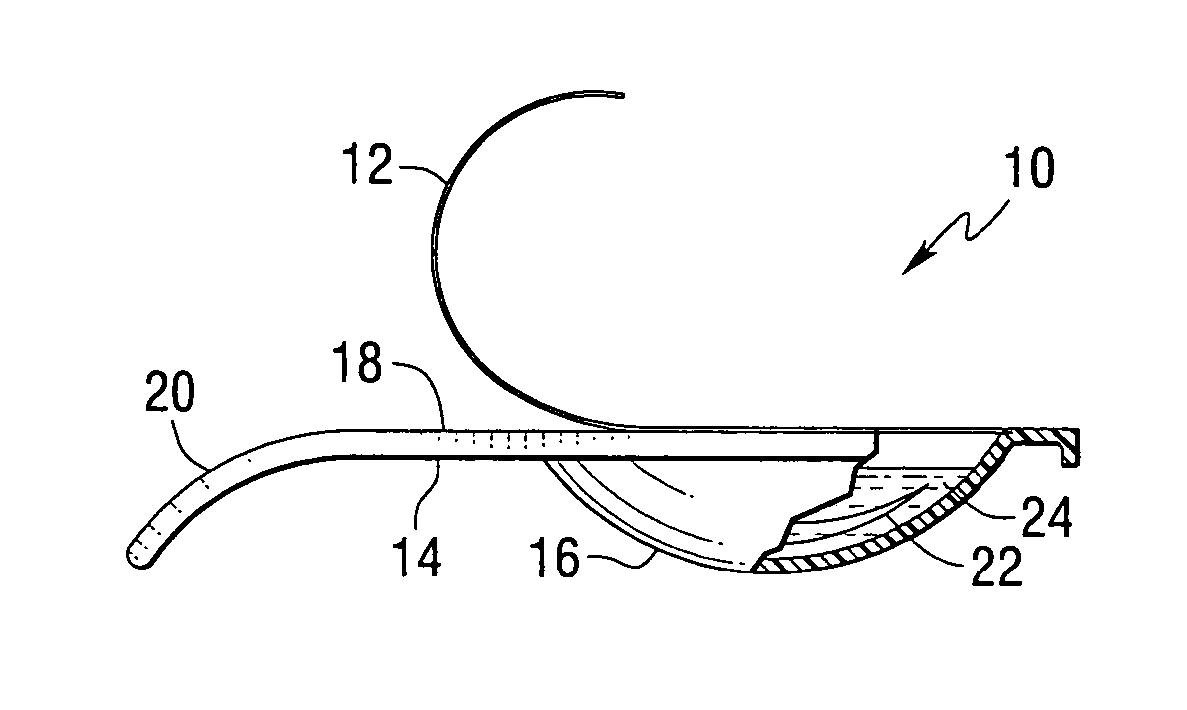

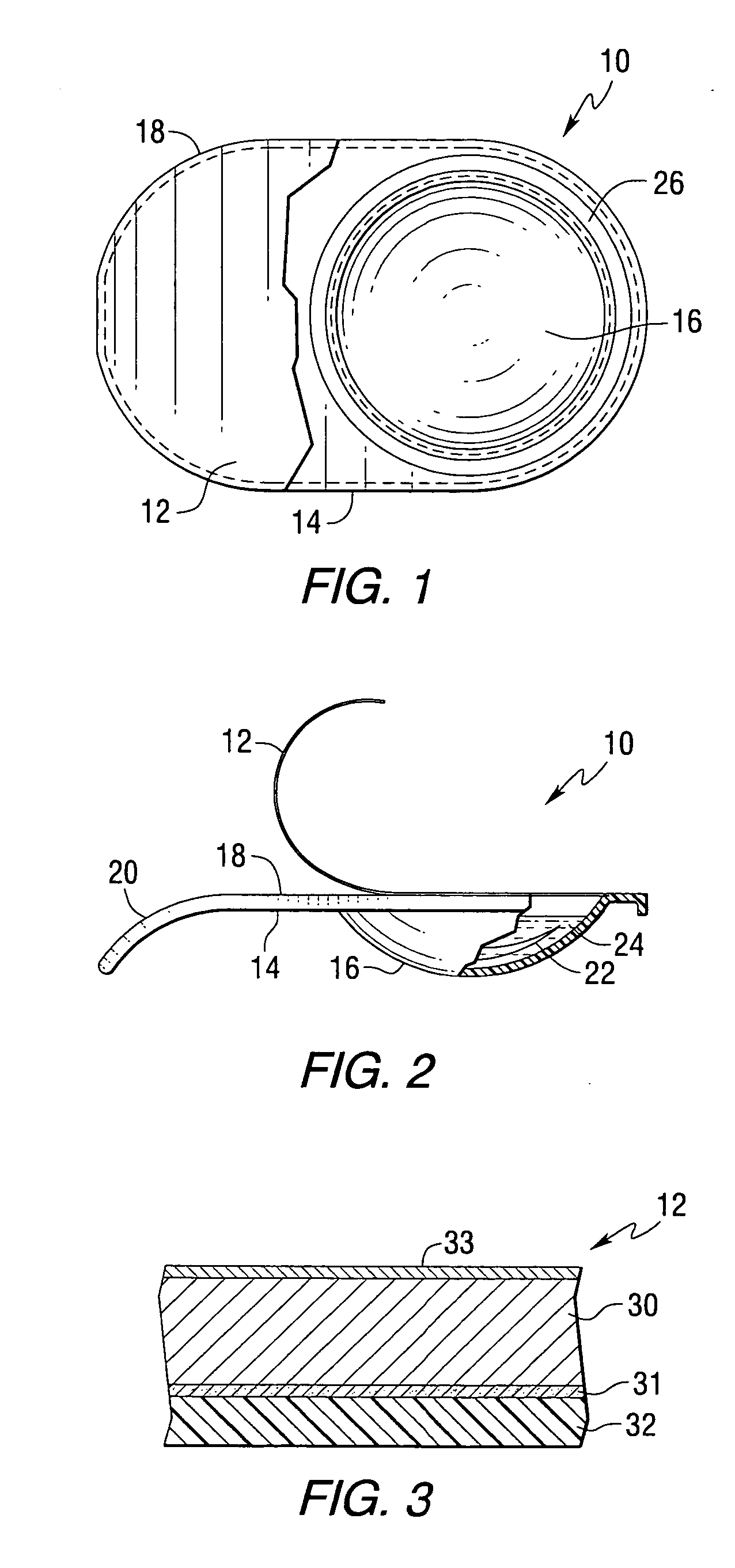

[0023] In FIGS. 1 and 2 there is shown one type of many varieties of containers that are useful with the lidstock material of this invention; a blister pack 10 made in accordance with the present invention, with a lid 12 partially peeled back to reveal its contents. While the present invention will be described with a blister pack this is in no way to be taken as limiting. The pack 10 comprises an injection molded plastic container body 14 heat sealed to the lid 12. The body 14 defines a bowl-shaped recess 16 having a diameter of about 2 cm. and a depth of about 0.5 cm. A flange 18 extending around the recess 16 includes a tapered curled lip 20 spaced apart from the recess 16.

[0024] The recess 16 here houses a contact lens 22 and a saline solution 24. The recess 16 is circumscribed by a seal area 26 which is part of the flange 18. The lid 12 is preferably attached to the body 14 by heat sealing in the seal area 26. Other suitable means for attaching the lid 12 to the body 14 includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com