Magnetic powder suitable for low-noise media

a magnetic powder and low-noise technology, applied in the field of iron system magnetic powder, can solve the problems of powder susceptible to sintering during the reduction stage, difficult to record, and more and more difficult to continue to exist as independent particles, and achieve strong prevention of sintering and high c/n.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

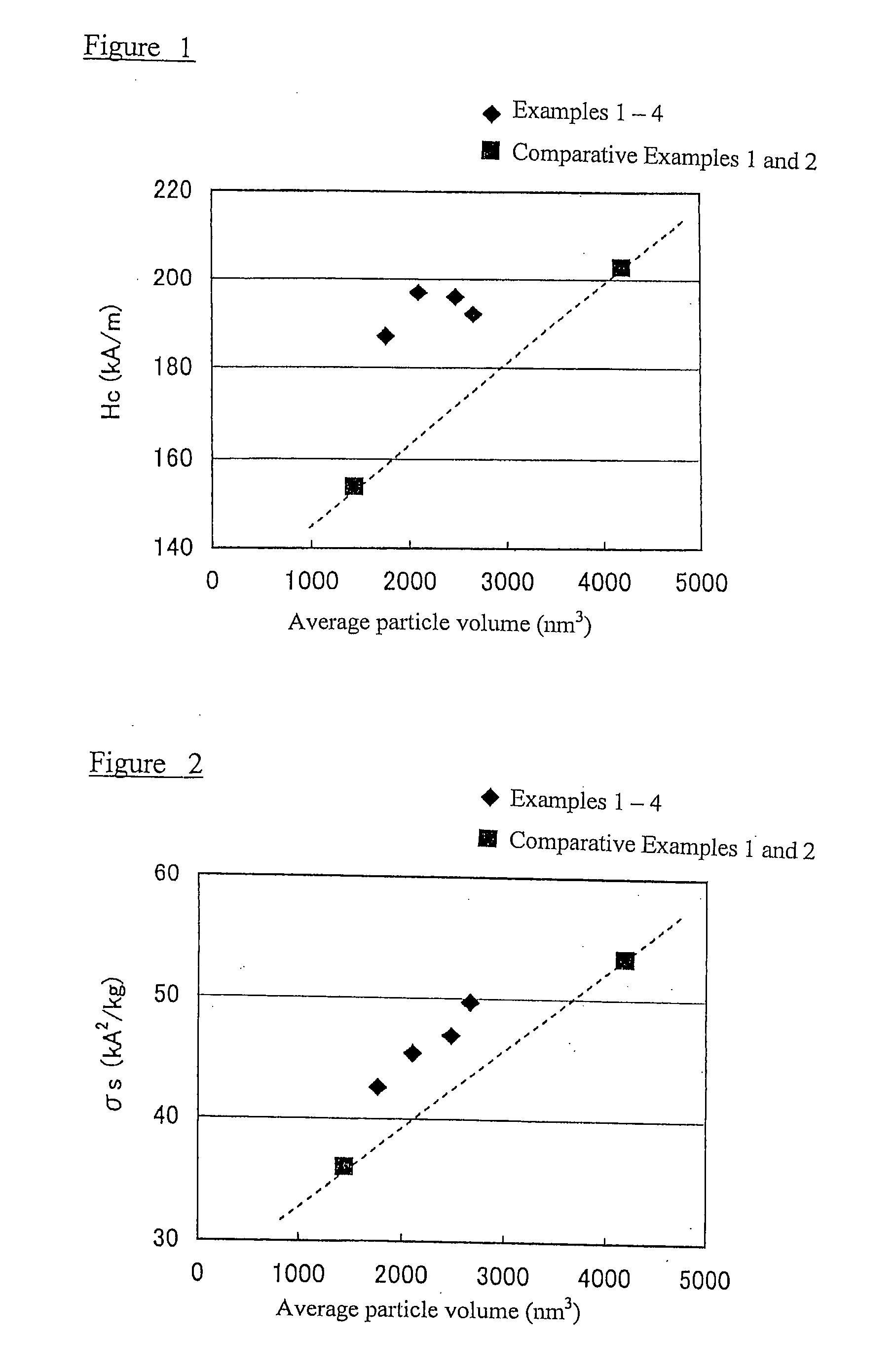

Examples

example 1

[0047] To 4 L (four liters) of a 0.2 mol / L aqueous solution of FeSO4 were added 0.5 L of a 12 mole / L aqueous solution of NaOH and an amount of ruthenium chloride to make Ru / Fe=0.1 at. %. The liquid mixture was maintained at a temperature of 40° C. while pure oxygen was blown into it at an average flow rate of 50 mL / min) on a period of 2.5 hours, thereby precipitating iron oxy-hydroxide (goethite) containing Ru in solid solution. Upon completion of this oxidation treatment, the precipitate (iron oxy-hydroxide) was filtered off, washed with water and then dispersed in water.

[0048] The dispersion was added with an amount of yttrium nitrate to make Y / Fe=1.0 at. % and then, at 40° C., with an amount of sodium aluminate to make Al / Fe=18.3 at. %, and with NaOH to adjust the pH to 7-8, thereby adhering yttrium and aluminum to the particle surfaces. The solid component was separated from the liquid by filtering, washed with water and dried in air at 110° C.

[0049] The so-obtained powder con...

example 2

[0051] Example 1 was repeated except that the amount of Ru added as a noble metal was changed to 0.5 at. %. The obtained powder was found by composition analysis to contain Al, Y and Ru at the rates of Al / Fe=17.9 at. %, Y / Fe=1.0 at. % and Ru / Fe=0.4 at. %. The properties of this mainly Fe16N2 magnetic powder are shown in Table 1.

example 3

[0052] Example 1 was repeated except that the amount of Ru added as a noble metal was changed to 1.0 at. % and the Ru was not incorporated in solid solution but as adhered to the particle surfaces. That is, Ru was not entrained in the iron oxy-hydroxide production reaction during synthesis of iron oxy-hydroxide by the wet method used in Example 1. Instead, ruthenium chloride was added to the liquid in which the synthesized iron oxy-hydroxide was dispersed, in an amount to make Ru / Fe=1.0 at. %. Ru was adhered to the iron oxy-hydroxide particles by the method of neutralization with NaOH, and then subjected to reduction treatment as the starting powder.

[0053] The obtained powder was found by composition analysis to contain Al, Y and Ru at the rates of Al / Fe=16.7 at. %, Y / Fe=1.0 at. % and Ru / Fe=0.8 at. %. The properties of this mainly Fe16N2 magnetic powder are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com