Package and device for simultaneously maintaining low moisture and low oxygen levels

a technology of oxygen level and moisture, applied in the direction of packaging foodstuffs, packaged goods types, pharmaceutical containers, etc., can solve the problems of unmarketable drugs, candidate to be excluded from development, reformulation and addition of standard antioxidants can take considerably more time and money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0076] A 20 mm Flurotec® Teflon stopper (West Pharmaceutical Services, Jersey Shore, Pa.) was drilled through the center with a 1.0 mm drill bit. HPLC tubing (Upchurch Scientific, Oak Harbor, Wash.) was cut to 2 cm in length and forced through the drilled hole in the stopper. The tubing used included model 1520 (762 μm inner diameter), model 1532 (508 μm inner diameter), model 1531B (254 μm inner diameter), model 1535 (127 μm inner diameter) and model 1560 (64 μm inner diameter), all from Upchurch Scientific (a division of Scivex Inc., Oak Harbor, Wash.).

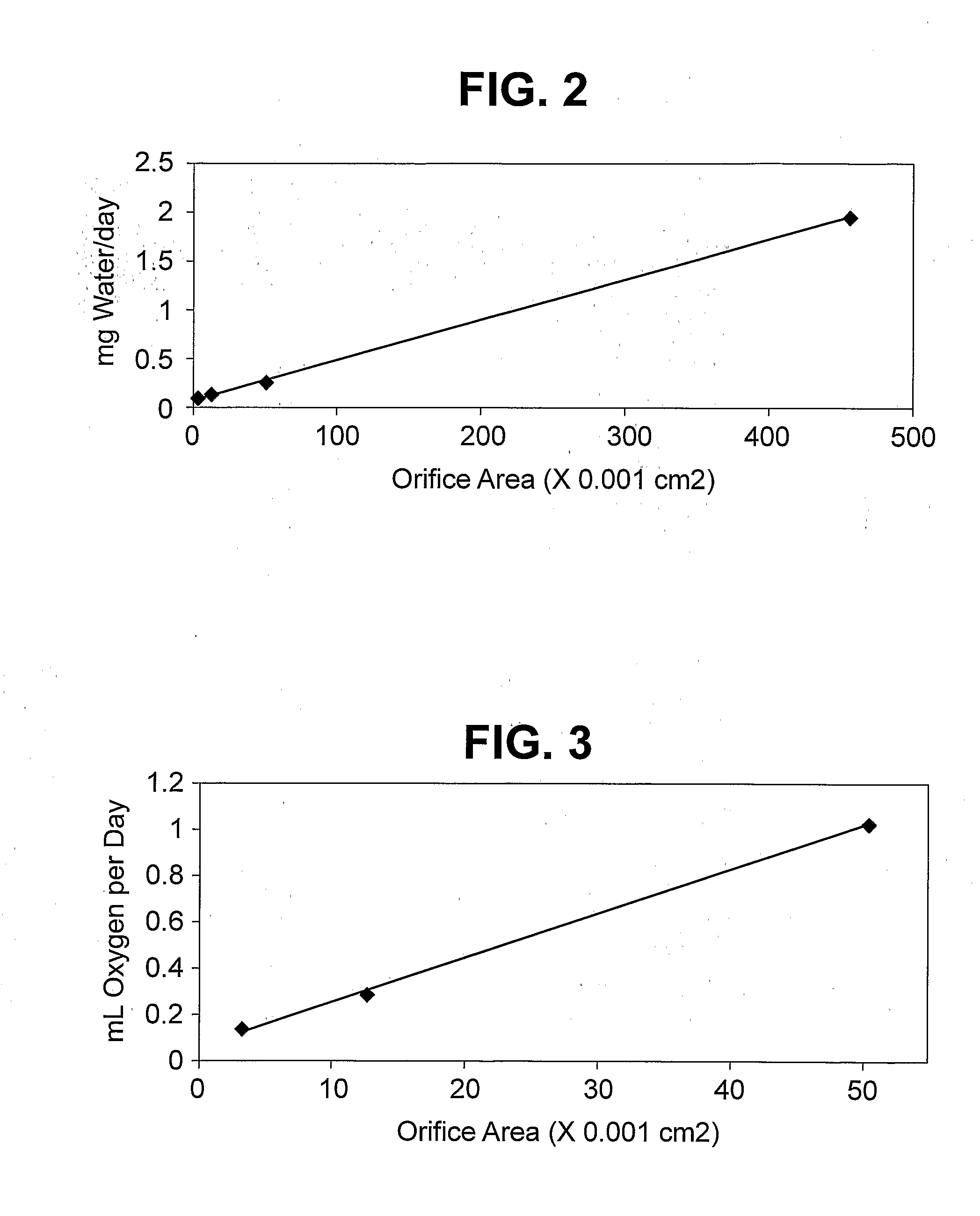

[0077] For the measurement of water vapor uptake, a 1 gram Sorb-It® canister (Süd-Chemie, Belen, N. Mex.) was cut open and the silica gel contents poured into a 10-cc tubular flint Type I glass vial (Wheaton Science Products, Syracuse, Nebr.). The stopper with tubing was crimp-sealed to the vial and the initial weight recorded. The test units were then placed in a 40° C. / 75% RH stability chamber and periodically weighed over two we...

example 2

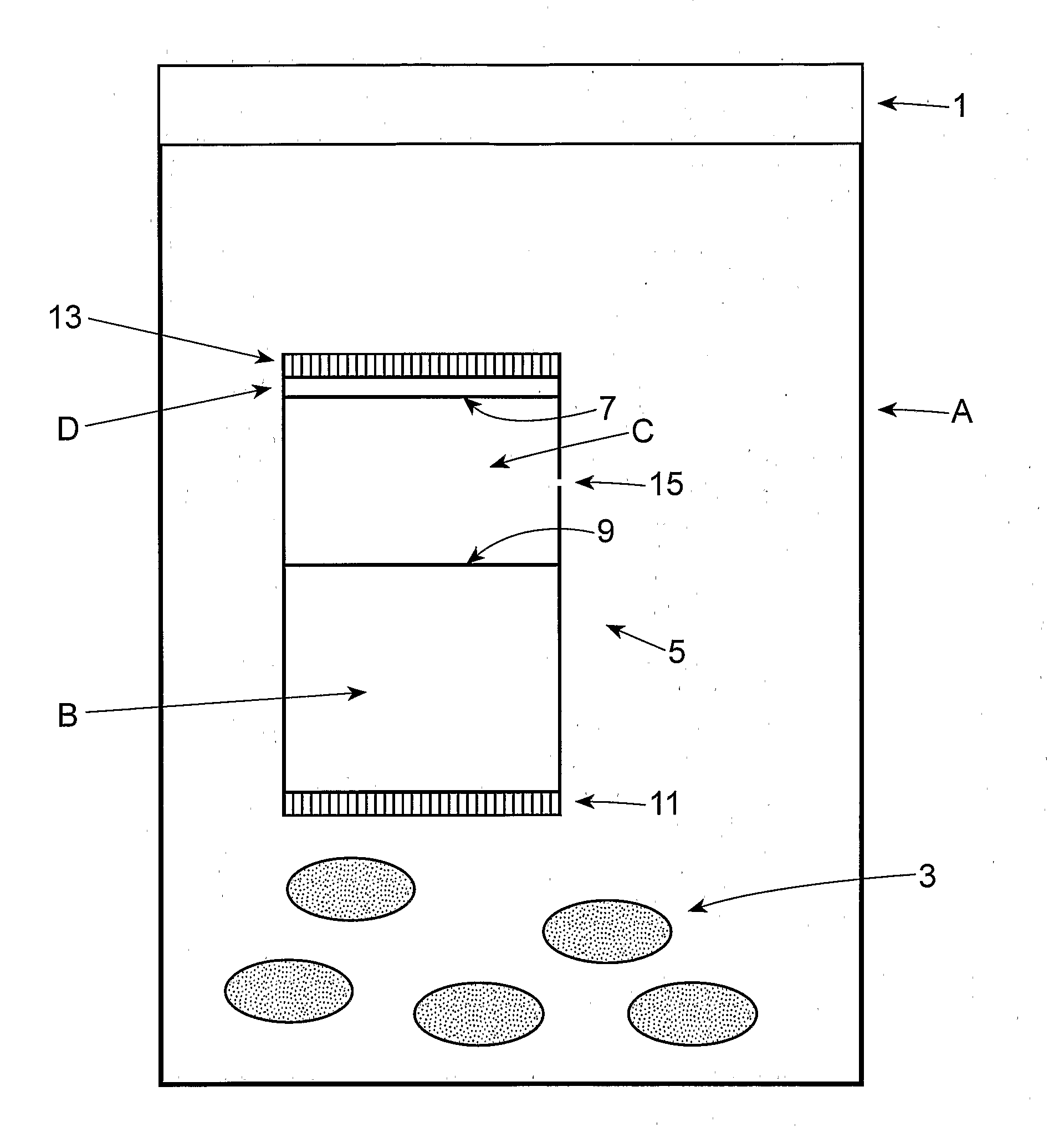

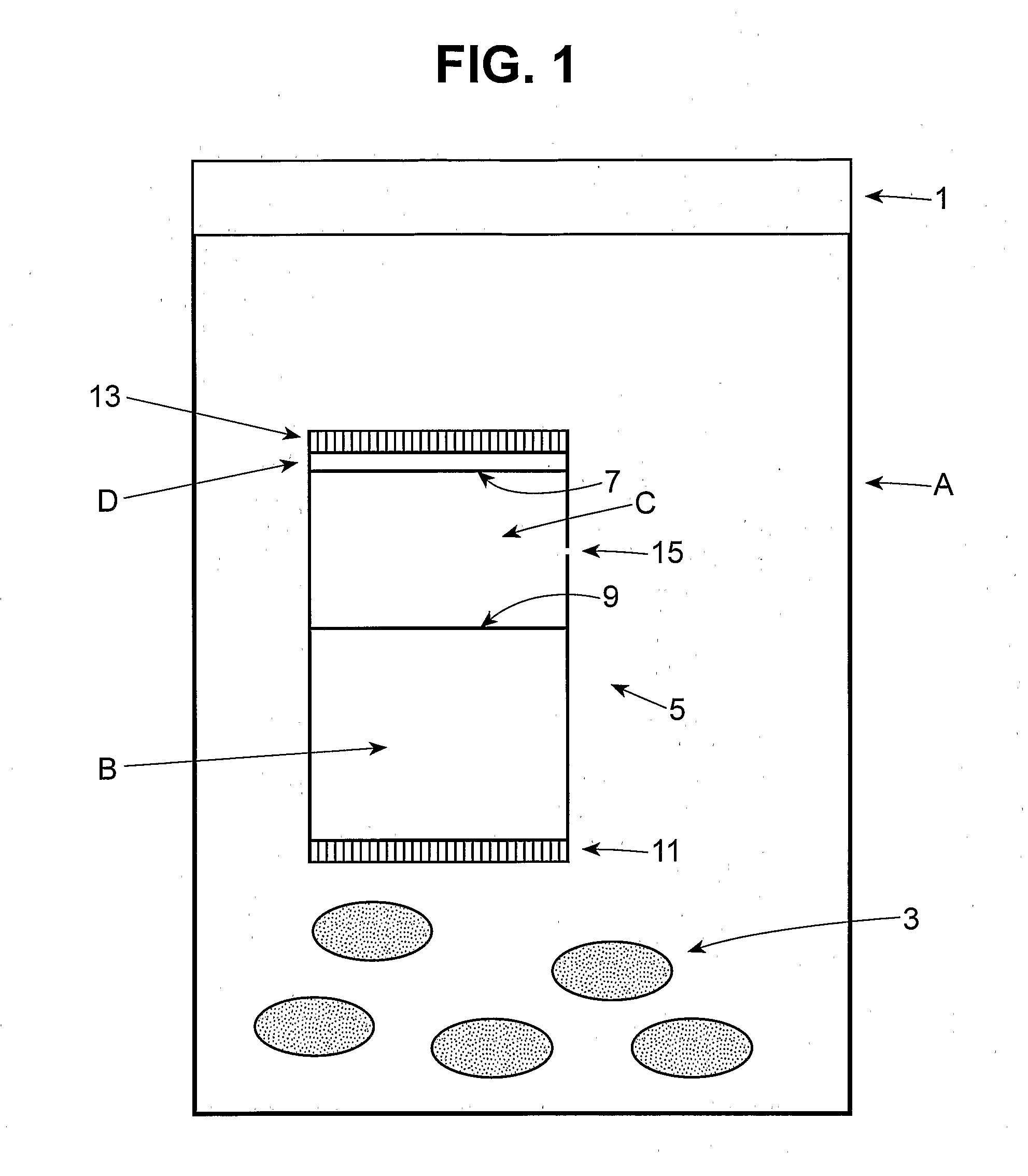

[0079] A cartridge is made by injection molding polyethylene into two compartments with cylindrical shape of diameter 0.5 inches (1.3 cm) and wall diameters of approximately 1 mm. The top compartment has a single 600 μm diameter hole with a lattice (diameter of openings of 25 μm) on the side as part of the mold. The bottom compartment is 0.25 inches in height (0.63 cm). The top compartment is 0.5 inches in height (1.3 cm). Into the bottom compartment is filled 0.5 g of silica gel. A cap of sintered polyethylene (porosity of 0.1) is adhered to the bottom compartment to seal in the powder. Magnesium nitrate (1.0 kg) is slurried with 800 g of water to give a 44% (w:w) slurry. The top compartment is filled with a combination of 300 mg of fine iron powder (as described in U.S. Pat. No. 5,725,795) and 450 mg of the magnesium nitrate slurry. A cap is formed by injection molding polyethylene into a cylinder with a wall and a top having a high porosity (0.4). The cap is 0.55 inches in diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com