Methods for the treatment of thrombosis

a metalloproteinase and thrombosis technology, applied in the field of thrombosis treatment methods, can solve the problems of not homogeneous and make sequencing impossible, and achieve the effect of greater homogeneity of the end produ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

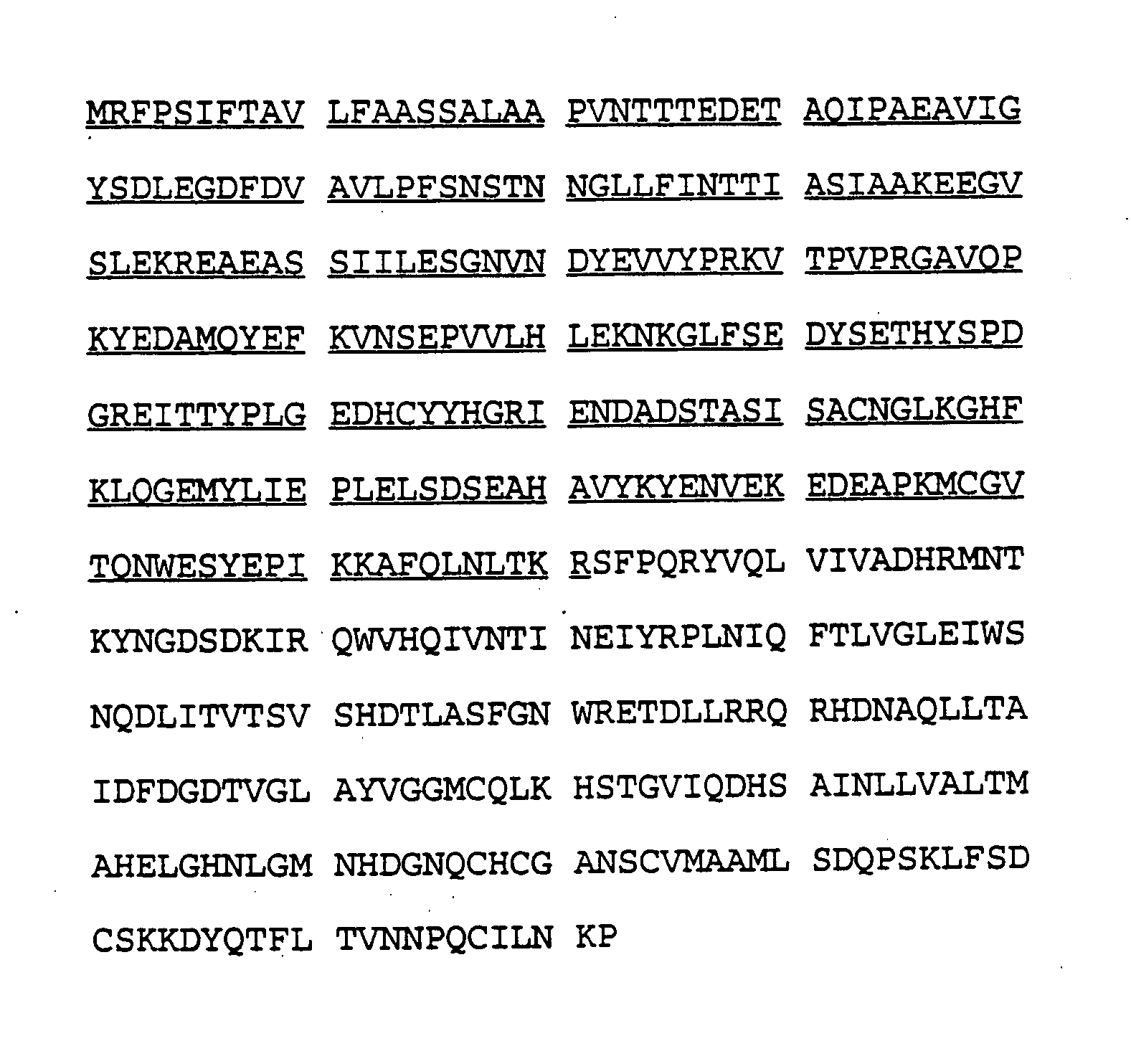

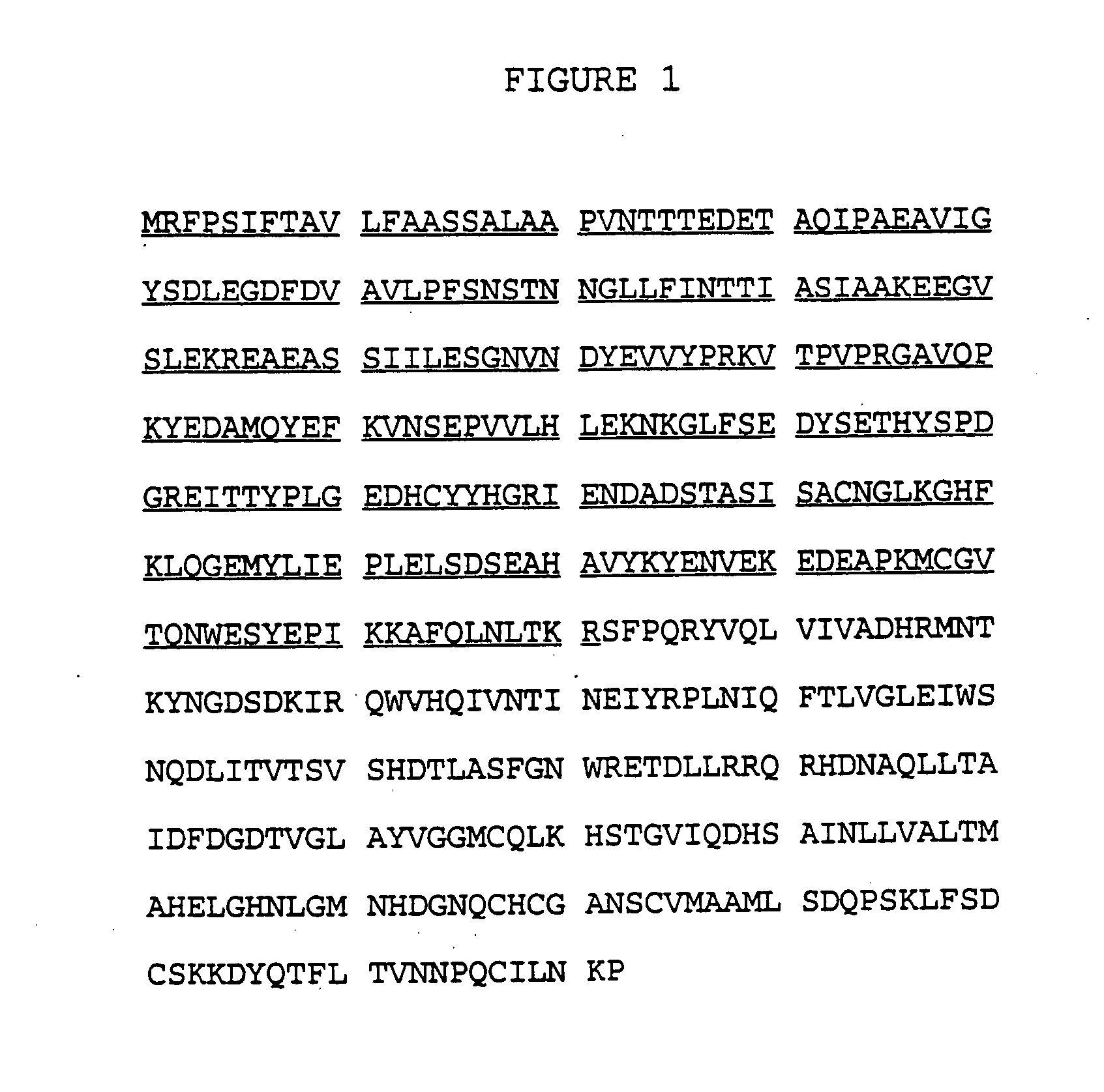

Derivation of NAT Sequence

[0052] An effective way to produce fibrolase is to express it initially as preprofibolase in which cleavage by the protease kex-2 occurs at the junction of the “prepro” and “mature” regions to yield biologically active material (“mature” fibrolase). From this design, the synthesis and processing of the preprofibrolase leads to secretion of mature fibrolase into the culture medium. The actual sequence at the cleaved junction is ( . . . TKR↓QQRF . . . ).

[0053] Kex-2 is an endoprotease that cleaves after two adjacent basic amino acids, in this case lysine(K)-arginine(R). Mature fibrolase expressed from DNA having the above mentioned sequence revealed that the expected N-terminal glutamine (Q) residue had in fact undergone deamidation and cyclization to generate pyroglutamic acid (E). This chemical modification was deemed undesirable, since peptides with an N-terminal cyclized glutamine (pyroglutamic acid) residue fail to react in the Edman-degradation proced...

example 2

Expression of NAT in Pichia pastoris

[0057] When attempts were made to express the DNA for NAT in E. coli, very poor refolding and a requirement for dilute conditions reduced the purification efficiency. These and other considerations led to the usage of Pichia pastoris, a yeast species, as the host cell. A culture of selected clones of Pichia pastoris which had been transfected with prepro NAT cDNA (SEQ ID NO: 4) was inoculated into 500 ml of the following inoculation growth medium:

Per liter of batch mediumYeast extract30.0gPotassium phosphate dibasic17.2gGlucose20.0gBiotin0.004gWaterto 1literPhosphoric acid, 85%to adjust pH to 6.00

[0058] The transfected P. pastoris cells were incubated at 30° C. in a shaker for about 30 to 32 hours. About 1% (w / v) of the resulting culture was used to inoculate a 10-liter fermentor. The fermentor contained sterilized basal salts and glucose (below). Twelve milliliters per liter of PTM4 salts (PTM4 is a trace metals solution containing cupric sulf...

example 3

Purification of NAT from Pichia pastoris

[0060] The yeast broth (conditioned media less cellular debris) from Example 2 was clarified and the pH and conductivity were adjusted to 6.5 and 10-20 mS / cm, respectively. The broth was loaded onto an immobilized metal affinity resin that had been charged with copper (Cu) and equilibrated with phosphate buffered saline (PBS). The resin was washed with PBS and eluted with an imidazole gradient (0-100 mM) in PBS. Fractions containing “mature” NAT (SEQ ID NO: 1) were pooled and diluted until the conductivity was less than 1.5 mS / cm, pH 6.4. The diluted pool was loaded onto an SP Sepharose resin (Amersham Pharmacia Biotech, Inc., Piscataway, N.J.) that had been equilibrated with 10 mM 2-(N-morpholino)ethanesulfonic acid (MES). The column was washed with MES and eluted with a NaCl gradient (0-500 mM) in MES. Fractions containing NAT were pooled and stored.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com