Alloy superconductor and methods of making the same

a superconductor and alloy technology, applied in the direction of superconductor details, superconductor devices, crystal growth process, etc., can solve the problems of weak distortion and fragile, lack of utility, and difficulty in conducting its production in a large volume and with good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]Hereinafter, the present invention will be described in detail with reference to suitable forms of implementation thereof illustrated in the drawing figures.

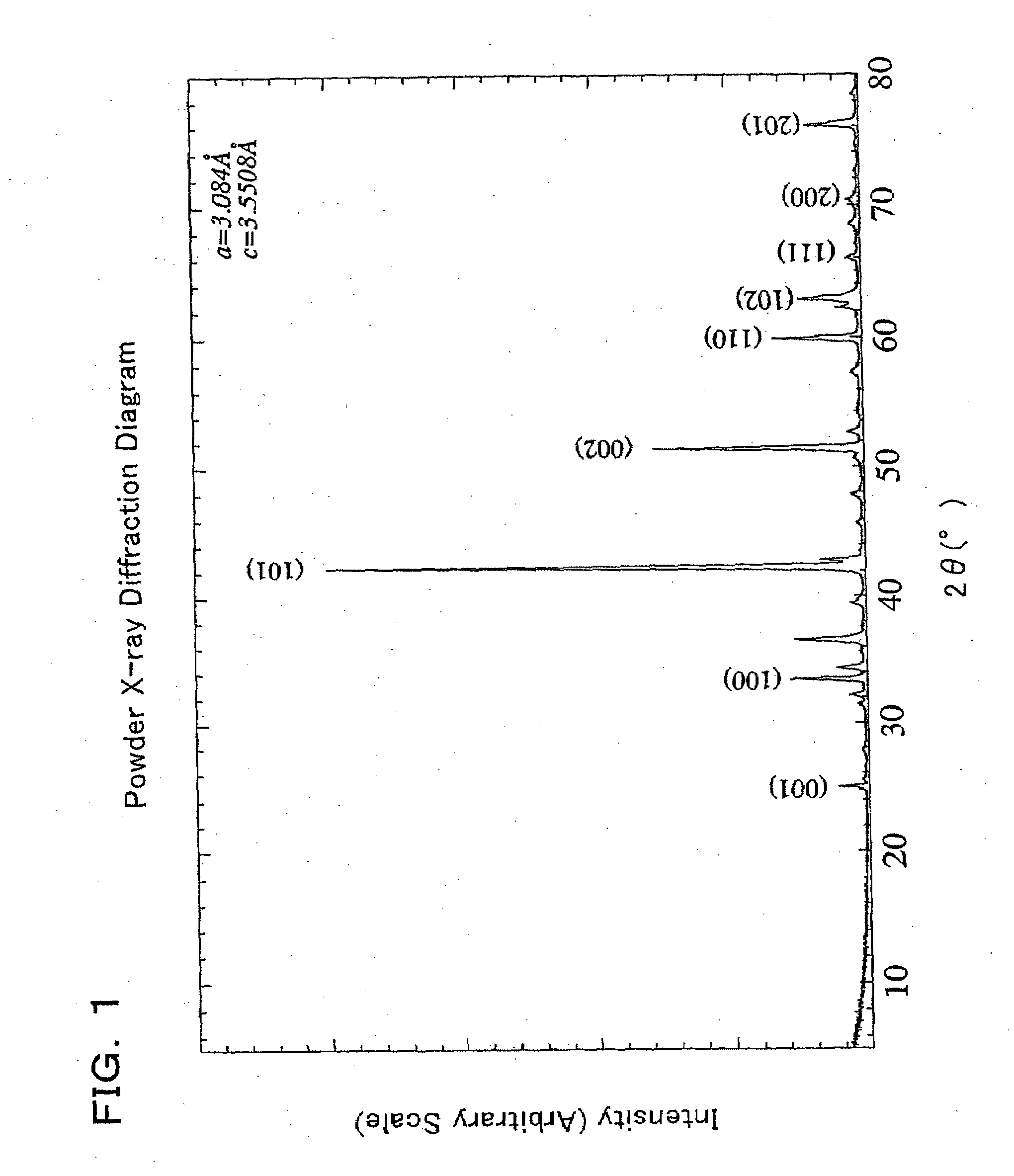

[0027]FIG. 1 is a diagram illustrating a result of powder X-ray diffraction measurements conducted of an alloy superconductor of a composition represented by composition formula: Mg1BexBy (where 0<x<20 and 0<y<20) according to the present invention.

[0028]The X-ray diffraction measurements were conducted using a biaxial X-ray diffraction analyzer (made by company RIGAKU, model RINT2000).

[0029]From the powder X-ray diffraction measurement pattern shown in FIG. 1, it is seen that the alloy superconductor of the present invention has a crystallographic structure that is hexagonal and belongs to the space group p6 / mmm. It is also seen that with its a-axis having a length of 3.084 angstroms and its c-axis having a length of 3.5508 angstroms, it is a hexagonal AlB2 type crystallographic structure.

[0030]Also in identifying the che...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com