Liquefied Petroleum Gas For LP Gas Fuel Cell, Method of Desulfurizing the Same and Fuel System

a technology of petroleum gas and fuel cell, which is applied in the direction of gaseous fuel, hydrocarbon oil treatment products, electrochemical generators, etc., can solve the problems of difficulty in complete desulfurization, increased sulfur content of supplied gas, and care for storage and loading of vehicles, so as to achieve the effect of effective desulfurizing agent and enhance desulfurization performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

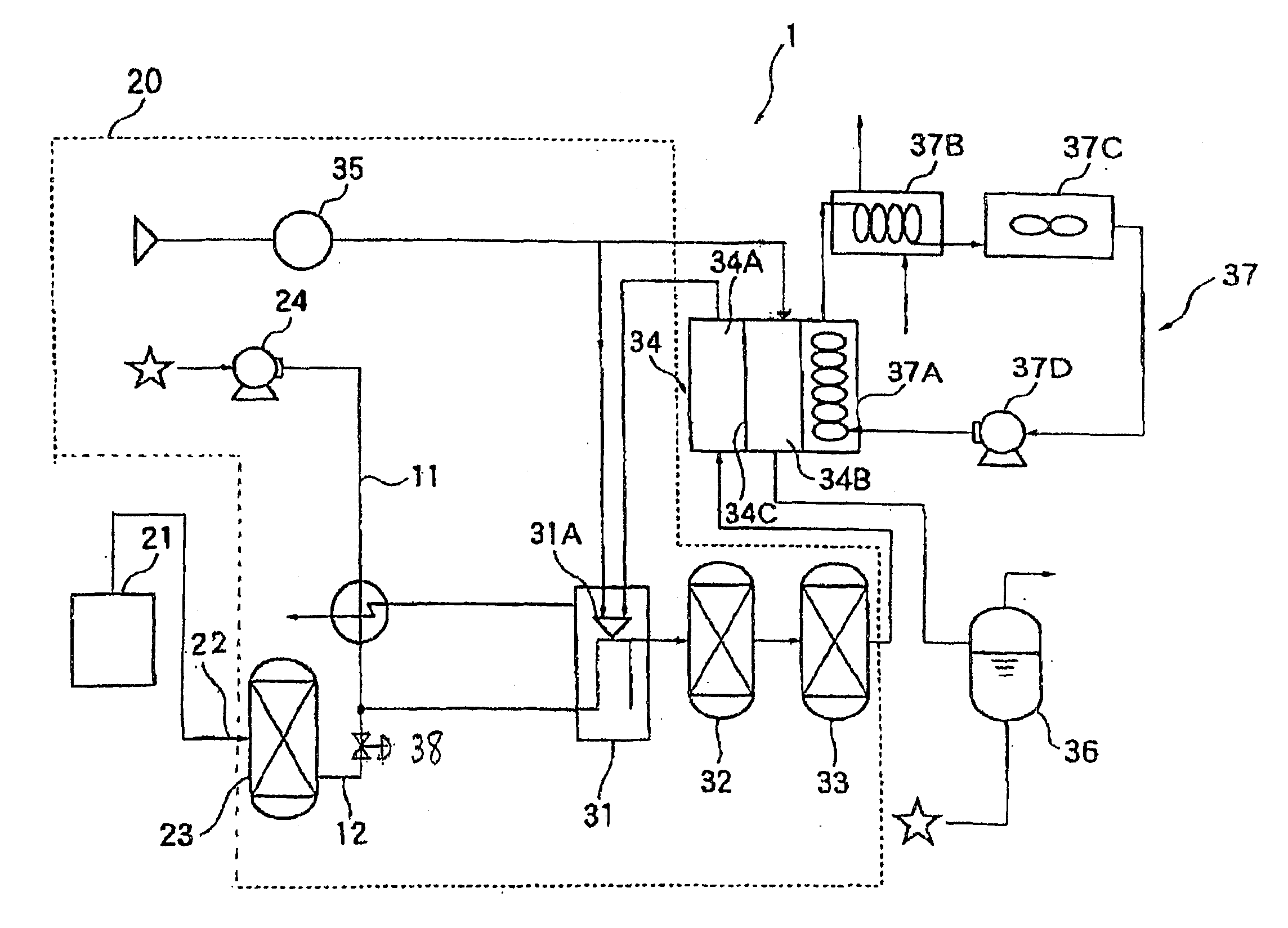

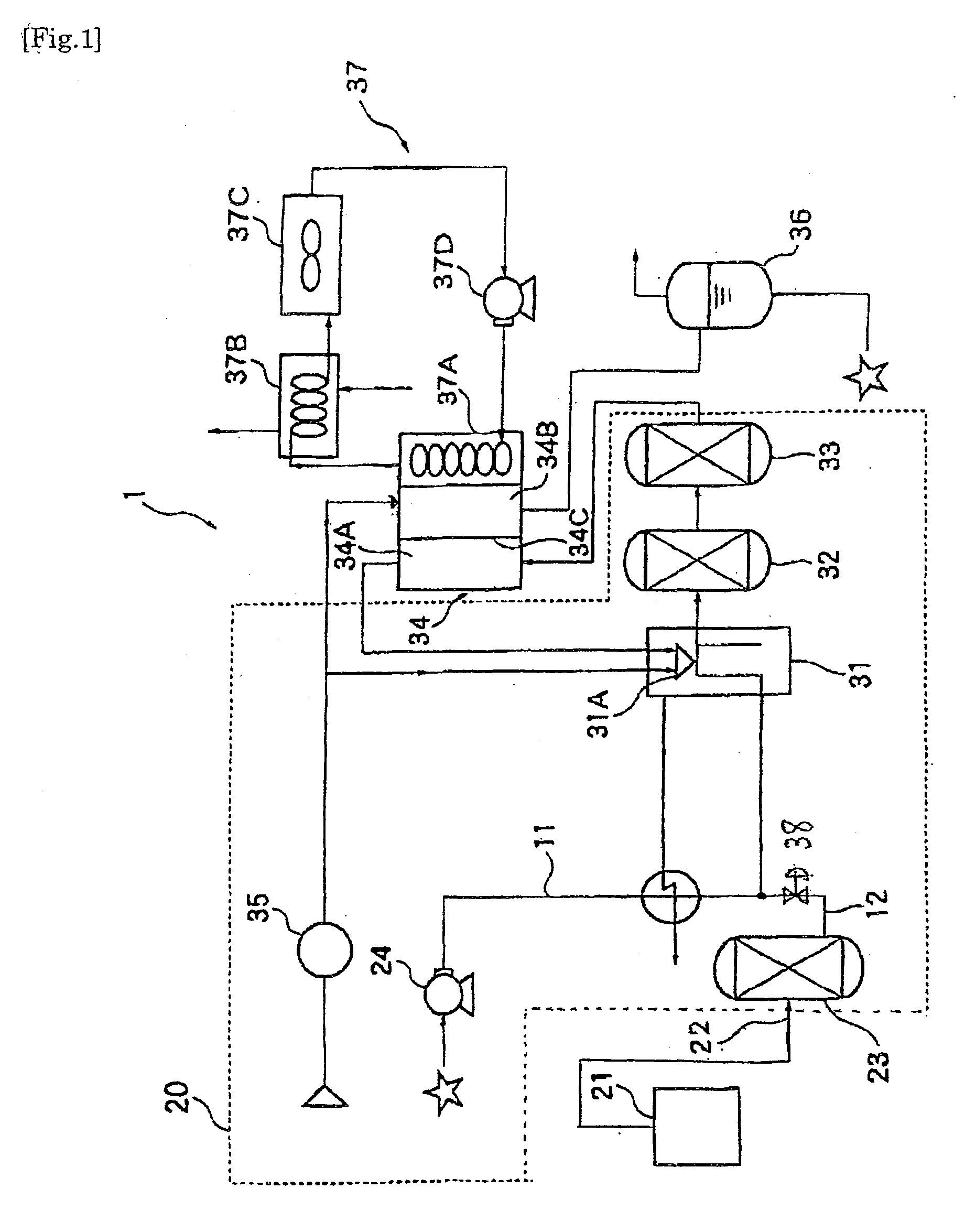

[0102]Liquefied petroleum gas fuel 1 having properties shown in Table 1 hereinbelow was supplied through spontaneous vaporization to a 1-kW polymer electrolyte fuel cell (PEFC) system employing LP gas. The system includes a desulfurizer, a reformer, a fuel cell stack, an inverter, etc. The desulfurizer is formed of a stainless steel container (diameter: 4 cm) in which desulfurizing agent A (300 mL) and desulfurizing agent B (150 mL) are charged. In the reformer, a commercial reforming catalyst (600 mL), a commercial shift catalyst (1 L), and a commercial selective oxidation catalyst (0.25 L) are charged. The liquefied petroleum gas fuel 1 was supplied to a fuel cell system, while the flow rate of liquefied petroleum gas fuel 1 was adjusted to 1.8 L / min by means of a thermal mass-flow controller (product of Ohkura Riken Inc.). Desulfurization was performed at ambient temperature and pressure. The reformer was operated at a reformer outlet temperature and pressure of 700° C. and 0.03 ...

example 2

[0103]The procedure of Example 1 was repeated, except that liquefied petroleum gas fuel 2 shown in Table 1 was employed. When the amount of used liquefied petroleum gas fuel 2 reached 0.5 mass % and 98 mass %, the cell output voltage was determined at a current of 33.3 A. The attained voltages were 39.0 V and 38.3 V, respectively.

example 3

[0105]Desulfurizing agent A (2 mL) was charged in an upstream portion of a desulfurizer (stainless steel, inner diameter: 10 mm), and desulfurizing agent B (2 mL) was charged in a downstream portion of the desulfurizer. Liquefied petroleum gas fuel 1 shown in Table 1 was supplied at 20 L / h to the desulfurizer maintained at 20° C. An automatic sampling port was provided at the outlet of the desulfurizer, and the total sulfur content was determined through gas chromatography by means of a sulfur chemiluminescence detector (SCD). The determination was performed under the following conditions: separation column: DB-1; path: 60 m; membrane thickness: 5 μm; ID: 0.32 mm; split ratio: 1:5; carrier gas: helium; flow rate: 23 mL / min; and temperature profile: 40° C. for 4 min, to 200° C. at 10° C. / min, and 200° C. for 15 min. As a result, after 160 hours from the start of the operation, the total sulfur content at the outlet of the desulfurizer reached 0.05 ppm by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com