Aa stacked graphene-diamond hybrid material by high temperature treatment of diamond and the fabrication method thereof

a technology of graphene and diamond, which is applied in the direction of polycrystalline material growth, after-treatment details, transportation and packaging, etc., can solve the problems of inability to assemble aa stacked graphene, etc., and achieves excellent physical properties, simple process, and maintain flatness in an atomic level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0039]AA stacked graphene-diamond hybrid powder was prepared by using diamond powder (size: 1˜2 μm) as a matrix (refer to FIG. 6a).

[0040]A device used for the high temperature treatment was a multi-cathode direct current power plasma diamond synthesizer. After diamond powder was placed on to a molybdenum substrate, the diamond / substrate set was placed on an anode of the synthesizer for plasma treatment. The conditions of the plasma treatment are as follows: 200 sccm of hydrogen gas, a pressure of 100 Torr, and a molybdenum substrate at a temperature of approximately 1200° C. (Surface temperature of the diamond matrix is expected to be higher than that of the substrate by several tens ° C.). A processing time was 1 minute.

[0041]According to the result of analyzing this sample by X-Ray Diffraction (XRD), as shown in FIG. 7, a (001) peak (2θ=22.9°) of the AA stacked graphene, together with a diamond (111) peak (2θ=43.8°) and a (110) peak (2θ=75.4°) was observed. This indicated epitaxia...

example 2

[0042]A diamond / silicon plate in which diamond having a thickness of 5 μm was deposited on a silicon substrate having a diameter of 4″ and a thickness of 0.5 mm was used as a matrix (refer to FIG. 6b), and was undergone the plasma treatment for 10 seconds under the same condition as Example 1.

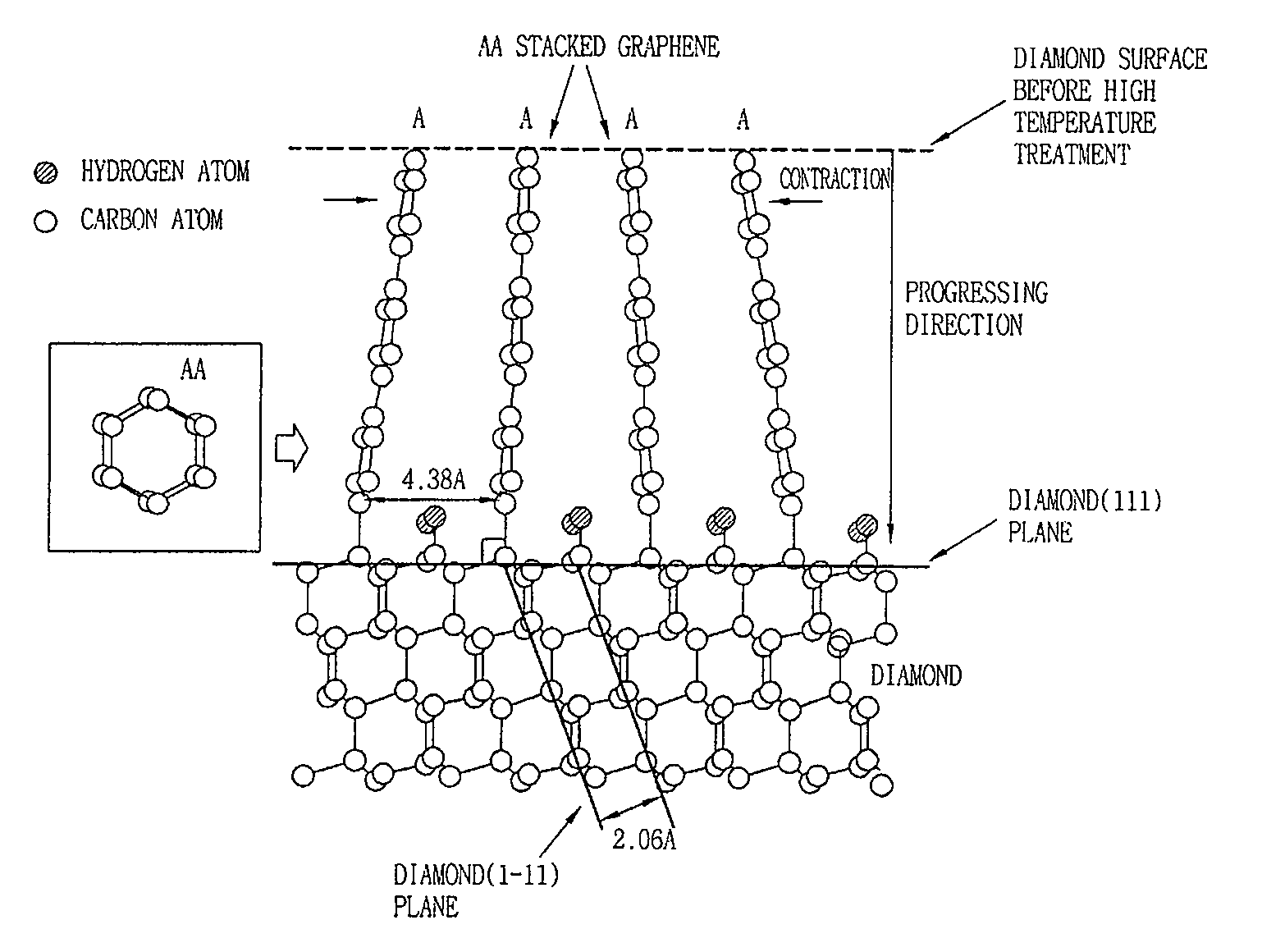

[0043]According to the result of analyzing the sample treated with the plasma by HRTEM, it could be observed that the thickness of the AA graphene layer was several nm, and the 2:1 conversion relationship between the diamond {111} lattice plane and graphene. Accordingly, the AA stacked graphene-diamond hybrid layer could be obtained on the silicon substrate.

example 3

[0044]A polycrystalline CVD diamond film having a ground (abraded, polished) texture (10×10×0.5 mm3T) was used as a matrix, and was undergone the plasma treatment for 10 minutes under the same condition as Example 1 (here, the substrate temperature was 1250° C.).

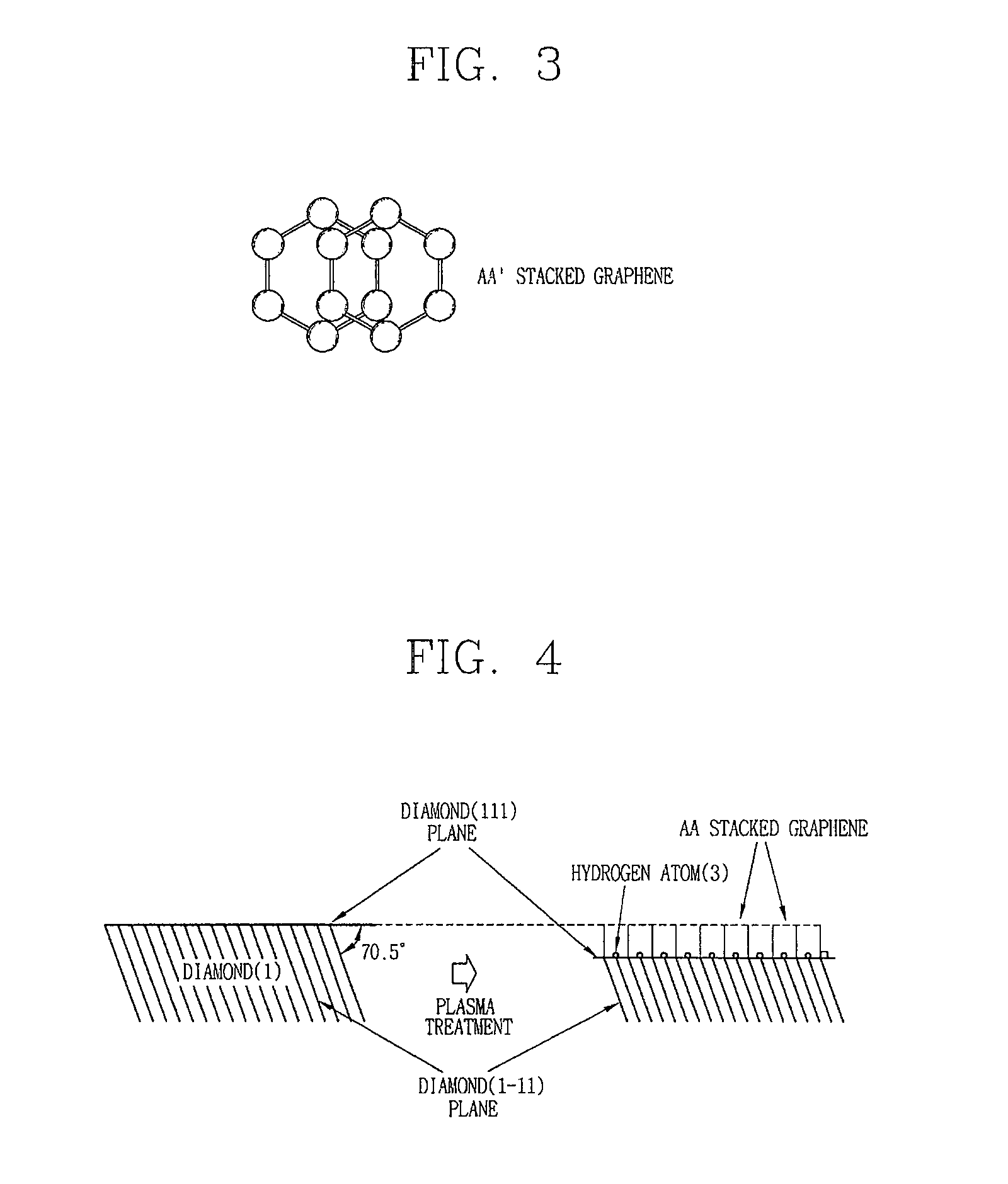

[0045]According to the result of analyzing the treated sample by HRTEM, it was observed that the thickness of the AA graphene layer was several hundreds nm, and the 2:1 conversion relationship between the diamond {111} lattice plane and graphene. According to the result of analyzing this sample by rocking curve XRD, it was observed that graphene was oriented having an angle of 60° with respect to the diamond surface (i.e., (110) plane). This is identical to the schematic diagram as shown in FIG. 5. Accordingly, it could also be checked that the formation angle of AA stacked graphene was changed on the diamond as the surface constituting the diamond surface is changed.

[0046]Meanwhile, due to the structural characteristic of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface temperature | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com