Method for formulating large diameter synthetic membrane vesicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

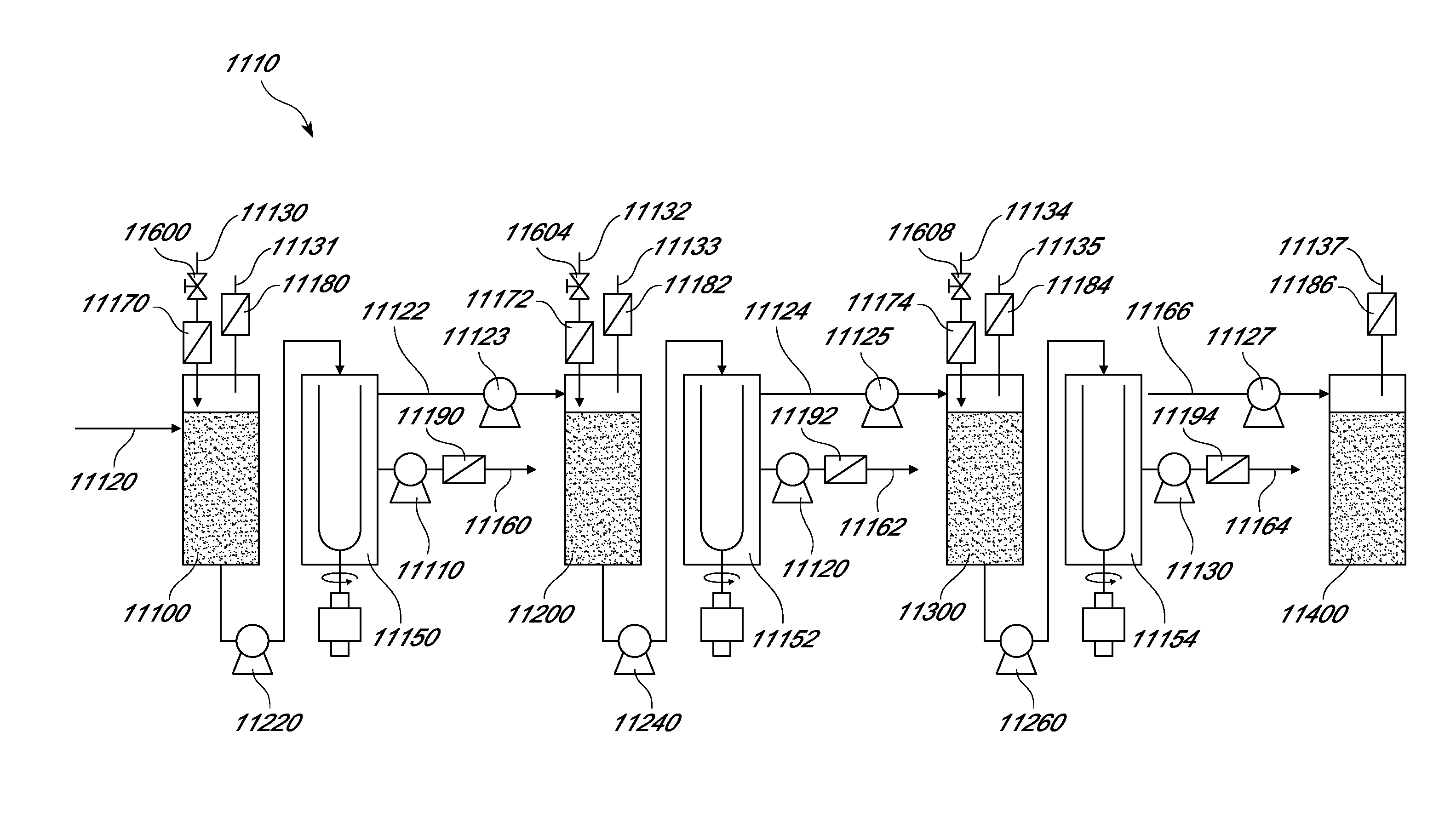

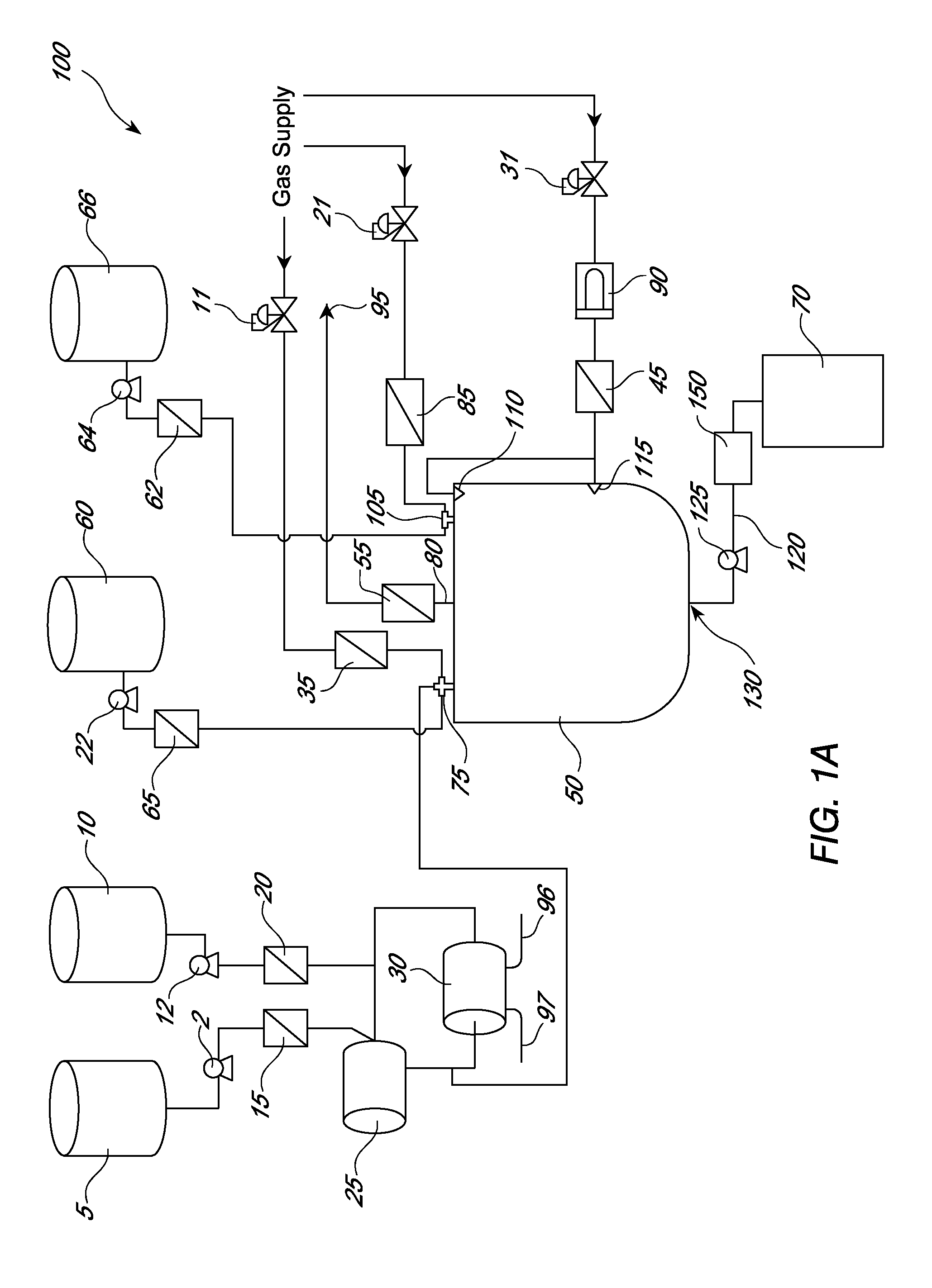

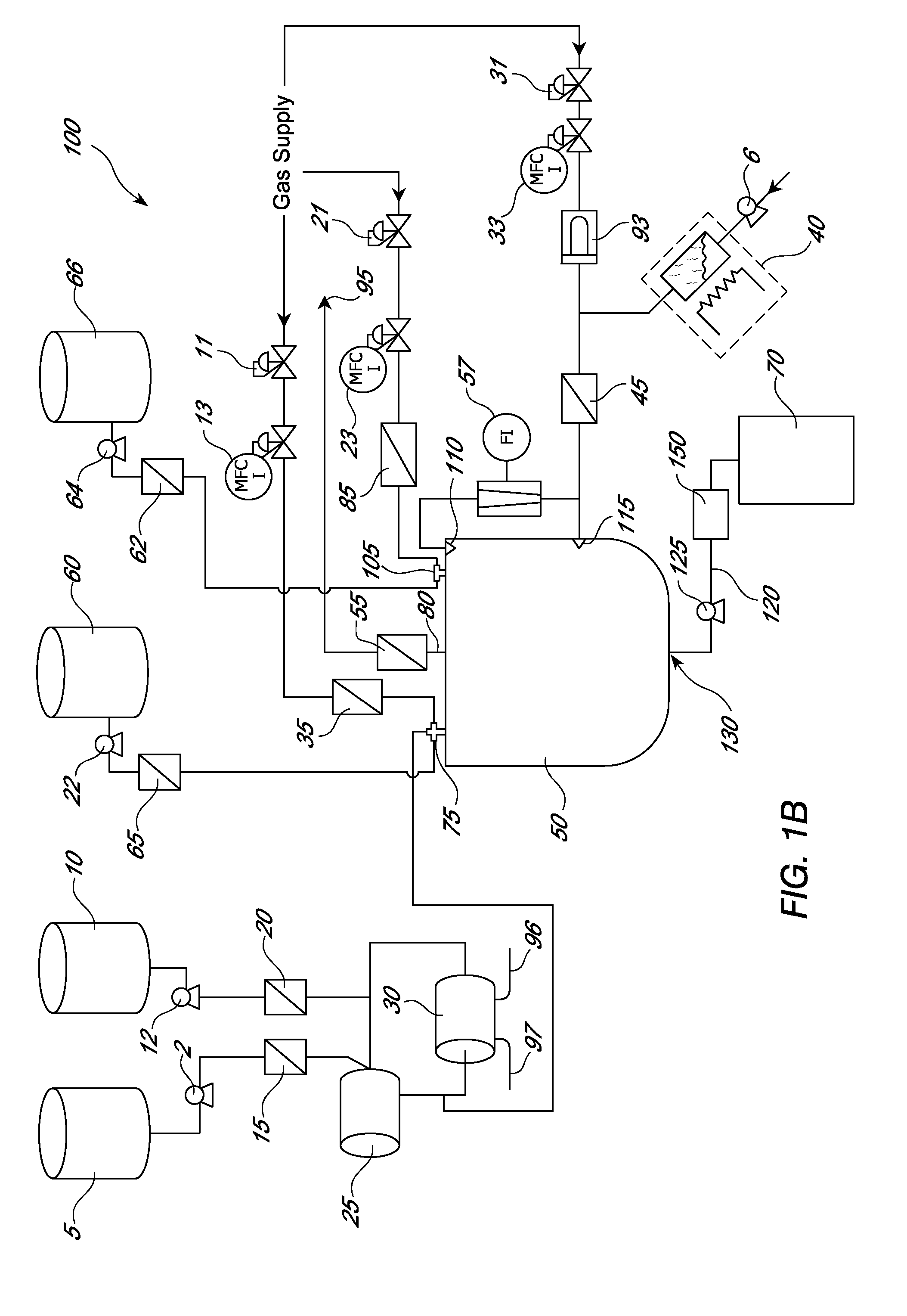

[0319]The following is an example utilizing the process parameters and steps of the devices depicted in the Figures. The three fluids applied to the atomizing nozzle (FIG. 1A and FIG. 1B, component 75; FIG. 3A, component 310; FIG. 7, component 7510) as part of the process of forming multivesicular liposomes have the following compositions per liter.

[0320]The first fluid (FIG. 3A-3L, component 3115; FIG. 5, component 5115; FIG. 7, component 7115) was a first liquid made up of the first component, the first component having two components: an organic phase and a first aqueous phase which are emulsified with equal volumes. The organic phase was composed of 1,2-dierucoyl-sn-glycero-3-phosphocholine (17.78 g), 1,2-dipalmitoyl-sn-glycero-3-phosphoglycerol (1.056 g), cholesterol (10.34 g), tricaprylin (4.32 g), water (0.70 g) and methylene chloride (quantity sufficient to make 1 L total volume of the organic phase. The first aqueous phase was composed of 0.2 molar (200 mM) phosphoric acid ...

example 2

Preparation of First Component

[0333]The recirculation loop connected to the high-shear mixer (FIG. 1A and FIG. 1B, component 25; FIG. 2, component 2130) (Ross Model HSM-703XS-20 Sanitary Inline High Shear Mixer equipped with a 3″ diameter X-5 Series rotor / stator for operation to 14,400 rpm. (11,300 feet / min. tip speed) with gap ring #3) was primed with methylene chloride to ensure that all air was removed from the high-shear mixer. The jacket of the heat exchanger (FIG. 1A and FIG. 1B, component 30; FIG. 2, component 2170) was supplied with 5° C. coolant (water+50% ethylene glycol). The mixer seal lubricant tank, filled with water, was also cooled with 5° C. coolant (water+50% ethylene glycol). The high-shear mixer was started at a setting of 25 Hz (6,000 rpm), 30 Hz approx. (7,200 rpm) or 35 Hz (8,400 rpm).

[0334]After the high shear mixer was primed with methylene chloride, the organic phase and first aqueous phase peristaltic pumps (FIG. 1A and FIG. 1B, components 12 and 2, respec...

example 3

Heat Treatment of MVL Suspension

[0342]The system of FIG. 1B was used with the humidified rotation gas (N2) supplied by combination electric heater and tube-in shell heat exchanger as described for FIG. 1A, component 90. The system was equilibrated for 10 minutes and a 1,000 ml sample of MVL suspension, exiting the drain port (FIG. 1B, component 130) of the solvent removal vessel 50, was collected. The MVL sample was divided into two samples of 500 mL each. The first 500 mL MVL sample was heat treated as follows. The heat treatment was performed by rapidly adding 750 mL of 100° C. dextrose solution to the first sample to raise the mixture temperature up to approximately 63° C. After 30 seconds, 1,750 mL of +5° C. saline was rapidly added to lower the temperature of the mixture to near room temperature (35° C. or below). The sample volume was now 3,000 mL. The second 500 mL multivesicular liposomes sample was not heat treated. The second sample was diluted with the same volumes of dex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com